Waste Plastic PET Bottle Recycling Line

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 20 Sets Per Month set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Detailed Product Description

waste plastic PET bottle recycling line

1,capacity:300-2000kg/h

2.,CE,ISO

3.Omron tranducer

4.OEM

waste plastic PET bottle recycling line

A.Technical Parameters

1. Belt conveyer

Transporter with frequency control, to adjust speed to requirements of line.

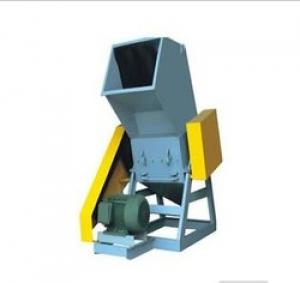

2. Crusher

This crusher is designed for wet crushing. It is equipped with eight rotating and four stationery knives. Crusher is supplied with standard grid size of 16mm and spare grid of 18mm. Input capacity is 1, 000kg/h can be increased with 18mm grid size.

3. Screw conveyer

Transport flakes from crusher.

4. Floating washing tank(3-4 sets)

Flotation/sink tank separate the material according their density. PET sinks to the bottom and is discharged by a screw conveyor. Remains of caps and rings made of PE and labels of PP floats on the top and are moved by rotating shovels to side of washing tank. Small screw conveyor take them out. This machine removes 90% of paper and plastic labels.

5. Friction washing tank

The flakes are efficiently cleaned inside inclining drum with blades on rotor turn

- Q: What plastic material has great impact resistance?

- Plastic raw materials Linai the maximum impact strength is MC nylon, the impact strength was > 500 kg. L cm / cm, nylon 11 cm / cm - 380 kg. The impact strength of polycarbonate, poly (phenol oxide), F-46, poly phenol, Yaan, low pressure polyethylene, polypropylene and nylon 1010 unreinforced is continuous".

- Q: What is the raw material used in the production of plastic products?

- The poisonous and harmful substances produced by plastics of this kind of material come from 2 aspects. One is the single molecule vinyl chloride which is not completely polymerized in the process of production, and the other is the harmful substance in the plasticizer (two). These 2 substances in the high temperature and fat when easy to precipitate, toxic substances enter the human body with food, easy to cause cancer. At present, the containers for this material are less used for packaged food. If the family has this kind of material, don't let it heat.

- Q: Is plastic bucket and plastic bottle the same raw material?

- When the number of the triangle in the bottom of the barrel is "1", the main component of this kind of plastic bucket is polyethylene terephthalate (polyester), which is often called PET. The melting point of this kind of plastic barrel is high, but the heat resistance can only reach 70 degrees centigrade, and it is easy to deform. When the temperature of the plastic barrel is higher than that of the plastic bucket, the possibility of dissolving harmful substances in the plastic barrel is increased, and the material such as wine, oil and the like can be easily twisted and contracted. As China has traditionally been thrifty, people tend to reuse plastic buckets. However, this kind of plastic barrels of repeated use, may release carcinogenic DEHP, if such liquid plastic barrel by people drinking, will may be suffering from cancer, also has toxicity to male testis, its harm should not be overlooked.

- Q: What kind of material is the raw material of plastic pipes?

- Plastic pipe raw material is plastic particles, according to the pipeline production processing performance requirements, with the different requirements of finished products, there are different manufacturers grades, grades and performance differences.

- Q: What are the POE plastic raw materials?

- Poe plastic raw material comes from petroleum or natural gas as the raw material of petroleum chemicals. It is a kind of macromolecule resin obtained by polymerization.

- Q: How to make plastic raw materials?

- polyethyleneFor short, PE is a thermoplastic resin made by the polymerization of ethylene. Industrially, it also includes copolymers of ethylene with a small amount of alpha olefins. Polyethylene is odorless, non-toxic, feel like wax, has excellent resistance to low temperature performance (minimum temperature can reach -70 ~ -100 C), good chemical stability, erosion resistance to most acid-base (not resistant to oxidizing acid), insoluble in common solvents at room temperature, low water absorption, excellent electrical insulation properties; but polyethylene for environmental stress (chemical and mechanical function) is very sensitive, heat aging resistance difference. The properties of polyethylene vary depending on the molecular structure and density. The products of different densities (0.91 ~ 0.96g / cm3) can be obtained by different production methods. Polyethylene can be used as a general thermoplastic forming method (see plastic processing). Widely used, it is mainly used for making films, containers, pipes, monofilament, wires, cables, daily necessities, etc., and can be used as high frequency insulating materials for television, radar and so on. With the development of petrochemical industry, polyethylene production has been developed rapidly, and the output is about 1/4 of the total plastic output. In 1983, the total production capacity of polyethylene in the world was 24.65Mt, and the capacity of the equipment under construction was 3.16Mt.

- Q: What are the raw materials for vest plastic bags?

- Polyvinyl chloride, referred to as PVC, and the formula is (CH2 - CH2) n, is the most important kind of vinyl polymer, is the world's second largest plastic varieties after polyethylene. In China, the yield is the first in plastics. In the printing industry, packaging production of books, folders, tickets and other frequently used PVC calendered film cover color and transparent glazing film.

- Q: PVC what is the difference between raw and recycled raw materials?

- Because the recycled material is a result of high temperature dissolved, it is likely to emit a pungent flavor, this odor may be harmful to humans.

- Q: What is the raw material for producing corn starch plastic film?

- It is corn starch raw materials of corn plant starch is a natural polysaccharide polymer, the molecular weight of up to 3 million Dalton, is a common concern at home and abroad can be used as the ideal material for the direct application of the polymer materials. Plant starch is divided into grain starch (corn starch, sorghum starch, wheat starch, rice starch) and potato starch (tapioca starch, potato starch, konjac starch).

- Q: What are the properties of plastic material PS? What are the advantages and disadvantages?

- The parameters of PS plastic (polystyrene) English Name: Polystyrene weight: 1.05 g / cm3 molding shrinkage rate: temperature: 170-250 degrees 0.6-0.8% molding material properties of electrical insulation (especially high-frequency insulation) excellent, colorless and transparent, light transmittance after organic glass, color of water resistance, good chemical stability, strength, but brittle that is easy to produce stress cracking, no resistance to benzene. Gasoline and other organic solvents. Suitable for production of transparent insulation. Trim and chemical equipment. Optical instrument parts forming performance.

1. Manufacturer Overview

| Location | Suzhou, Jiangsu, China (Mainland) |

| Year Established | 2004 |

| Annual Output Value | US$50 Million - US$100 Million |

| Main Markets | North America; South America; Eastern Europe; Southeast Asia; Africa; Oceania; Mid East; Eastern Asia |

| Company Certifications | ISO 9001:2000; ce |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b) Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | |

Send your message to us

Waste Plastic PET Bottle Recycling Line

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 20 Sets Per Month set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords