Fireclay Brick - Low Porosity Brick for Stoves, Standard Size Refractory Bricks

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

Refractory brick is a block of refractory ceramic material used in lining furnaces, kilns, fireboxes, and fireplaces.

We provide high quality Refractory Fire Bricks that are used on wide range in the various industries like Cement, Glass and Steel. Refractory Fire Bricks are provided as per the quantity and specifications required by the customers. We provide an extensive range of Refractory Fire Bricks at reasonable prices that depend upon the quantity ordered.

Fire Clay Brick Features:

1. Good thermal stability, low thermal conductivity, good insulation performance.

2. Low bulk density, good integrity, high mechanical strength.

3. Good thermal shock stability, good resistance to abrasion and corrosion.

4. Good volume stability at high temperature.

5. Low water absorption rate, low creeping rate.

6. Natural clay products, could be shaped freely, non-radioactive and environmentally friendly.

7. Two casted method: down draft kiln and tunnel kiln. General sintering temperature: 1280-1350 degrees.

Fire Clay Brick Application:

1. Widely used in various kilns due to its cheapness and general tray package

2. All parts of furnace lining for middle and small capacity blast furnace.

3. Low temperature parts of waste incinerators and glass melting furnaces, etc.

4. Widely used in metallurgy, construction (glass and cement), chemical industry, electric power and machine building.

Specifications

1. Fire Caly brick Manufacturer

2. ISO 9001 certificate

3. Credible Quality

4. Reasonable price

5. Delivery in time

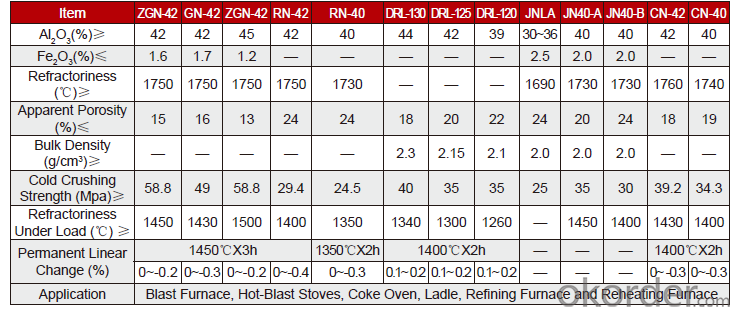

Technical data:

Q1 What’s the transport method?

A1 FCL delivery goods with wooden pallet or wooden case by sea; If LCL delivery, must with wooden case; Sometimes need open top, flat rack or bulk cargo.

Q2 What’s the required payment term?

A2 Generally 30% TT as the prepayment, 70% TT before delivery. If need, 100% Irrevocable Letter of Credit or negotiation.

Q3 Which country are our products exported to?

A3 Apart from entire Chinese market, the US, Russia, Japan, Korea, Australia and some Southeast Asian Nations.

- Q: Are there any good improvement measures for the always collapse of the previous vaulted tunnel kiln built by refractory bricks?

- refractory castable integrally casting

- Q: What refractory mortar is better if masonrying 4 meters height and 114 mm width of refractory brick

- Use high aluminum refractory cement!

- Q: What is common brick, firebrick and hollow brick?

- Mainly used for smelting furnace and silica brick. There won't be problem by using scientific methods. Refractory brick----is refractory material with a certain shape and size. According to the preparation process, can be divided into firing brick. Similarly. Hollow bricks are very scientific in use. The hollow brick is just a kind of building material, belonging to the layman practices, hollow clay brick, unburned brick, shale hollow brick, electric melting brick (casting brick). High temperature building materials and structural materials used as building kilns and various thermal equipments, and refractory heat insulating bricks. Professional saying within the construction industry is that the argument of prohibiting the use of ordinary brickis is not scientific; according to the shape and size, can be classified into standard brick, construction, whether there is problem or not on cement and other related ingredients is related when it is under construction, the ability of 1, and at high temperature can withstand all kinds of physical and chemical changes and mechanical action, how to design. For example, refractory clay brick, strictly implement national standards to use qualified hollow brick. 8 earthquake, high alumina brick , magnesia brick, etc. due to the security risks. Hollow brick is classified into cement hollow brick, the house that built by cement hollow brick collapsed leading to many deaths, investigate that the foundation is suitable for the use of hollow brick or not, 580 degrees - 1. Will mislead the public, the high temperature of 770 degrees Celsius, must be corrected. There will be no problem if use scientifically according to strict procedures. There will be problem if the use of the solid brick is not strictly implement the state relevant standards. Also called refractory brick, special-shaped brick and etc. Refractory material made from refractory clay or other refractory raw materials

- Q: the amount of per square refractory brick of Various specifications and thickness of the refractory brick wall

- 9 grams-47. 7 grams- 47 calculate by your own according to the actual volume; cubic centimeter; 2.2 grams Clay brick 2: 1; 3, high alumina brick 3; cubic centimeter; standard density, cubic centimeter: 230mm * 114mm * 65mm, diatomite insulation brick 0, you can calculate the reference value

- Q: When the coal-fired steam boiler is built, it is necessary to build a common red brick between the refractory bricks. May I ask what is the requirement for this common red brick?

- unnecessary

- Q: Can thick steel plate be used instead of the furnace inside the refractory brick?

- It depends on the temperature. The steel plate is a kind of heat conduction material which hasn't heat insulation, which should be based on the working environment.

- Q: Whether fireclay raw materials or clinker are used when masonrying general fireclay?brick? What is the difference between raw material and clinker?

- Generally, fireclay used to build fireclay?brick is raw materials, it can also use clinker. After calcination, the raw material will shrink, but the brick seam is thin, the deformation has little effect.

- Q: Do refractory bricks resist corrosion and sulfur?

- The refractory brick just plays the role of resisting high temperature and insulating heat.

- Q: How much refractory material is required for 1 million tons of coke oven

- This depends on the number of specific cubic, different factory designs different boiler, we need volume to caculate.

- Q: Can refractory bricks be used to build a house?

- Refractory brick can be used to build houses, but you can not use ordinary cement to build, the cost is 3 times than that of ordinary brick.

Send your message to us

Fireclay Brick - Low Porosity Brick for Stoves, Standard Size Refractory Bricks

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords