Fireclay Brick Corundum Brick of Refractory Brick for Steel Industry

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details for Refractory Fireclay Brick For Steel Industry

| Place of Origin: | China (Mainland) | Shape: | Block | Material: | Alumina Block |

| Al2O3 Content (%): | 40 | Refractoriness (Degree): | Common (1580°< Refractoriness< 1770°) | Model Number: | JN40-B |

| Brand Name: | CMAX | Refactories(℃): | 1730 | Bulk Density(g/cm3): | 2.0 |

| Apparent Porosity(%): | 24 | C. C. R. Strength(MPa): | 30 | Refractories Under Load(℃): | 1400 |

| Al2O3(%): | 40 | Fe2O3(%): | 2 | Reheating Linear Change(%): | \ |

Packaging & Delivery

| Packaging Details: | Pallet |

| Delivery Detail: | 25 days |

Price for Fireclay Brick Corundum Brick of Refractory brick Made in China

Product Description

High alumina fireclay Brick for Heating Furnace is a kind of insulation material adopting organic matter as ignition loss substance in order to increase the porosity of refractory, which has such advantages as high porosity, small volume density, good insulation effect, high mechanical intensity, small thermal conductivity and long service life. For various industrial kilns & furnaces, it is a kind of essential refractory for energy saving and temperature preservation.

This series of High Alumina fireclay Brick for Heating Furnace are made of selected high alumina bauxite, kaolin caly, hollow microsphere as the mian material.By shaping at high pressure and sintering at high temperature.

Fireclay brick is shaped refractory product.It is made from flint clay clinker and binder , Through high heat sintering. The Al2O3 content range from 28% to 48%.The refractoriness range from 1580°C to 1750°C(SK-30.SK-32.SK-34.SK-35).

Product Applications:

High alumina fireclay Brick are ideal for use in the below applications

Furnaces of metallurgy industry, heat treatment furnace

Furnaces of chemical industry and construction industry.

Furnace of incineration of garbage, recirculating fluidized bed furnace

Standard sizing: 230 x 114 x 65 mm others up to the client

Product Advantages:

CNBM has success in its Fireclay brick due to their cost-effectiveness and excellent insulating properties. CNBM also has experience in ceramic fiber blankets application and would like to assist you in product selection, system design, and installation techniques.

Main Product Features:

High refractoriness,High-temperature endurable .

Good corrosion resistance.

Good spalling resistance and wear resistance.

Good thermal shock resistance.

High mechanical strength.

High-temperature creep rate is low.

Good volume stability at high temperature.

Product Specifications:

ITEM | UNF42 | UNF46 | ZGN42 | RN40 | TDL45-12 |

Refractoriness, ℃ | 1730 | 1750 | 1750 | 1730 | 1760 |

Bulk Density, g/cm3 | 2.15 | 2.25 | 2.3 | 2.15 | 2.37 |

Apparent Porosity, % | 22 | 20 | 15 | 24 | 12 |

C.C.S, Mpa | 30 | 35 | 58 | 28 | 68 |

Refractories Under Load (0.2Mpa),℃ | 1400 | 1420 | 1450 | 1430 | 1500 |

Reheating Linear Change, % | 1400℃x2h 0.1~-0.4 | 1430℃x2h 0~-0.1 | 1450℃x2h 0~-0.2 | 1350℃x2h 0~-0.3 | 1450℃x2h -0.1~+0.05 |

Al2O3 Content , % | 42 | 46 | 42 | 40 | 45 |

Size :

Common sizes

Straight type | Arch type | Wedge type |

L×W×H (mm) 230×114×65 230×114×75 230×114×32 220×110×60 220×110×50 220×110×40 220×110×30 | L×W×H/h (mm) 230×114×65/55 230×114×65/45 230×114×65/59 220×110×65/50 220×110×75/65 220×110×60/40 | L×W×H/h (mm) 230×114×65/55 230×114×65/45 220×110×75/65 220×110×60/40 |

Other sizes according to customer requirements | ||

![]()

1.Strong professional:

A:The manager of our company has 50 years working experience in refractory product, technology and trading. He has professional function on a various refractory’ s production materials, process control, quality supervision and package delivery.

B: .Company staff are very familiar with refractory and professional knowledge is very good .

C:Company staff are all college culture level.

2. .Annual supply:

Our company has a dozen cooperative production factories which are better in productive technology and quality management. All the factories has passed ISO9001 quality management system certification. And the annual supply of dense shaped and unshaped refractory product is 100,000-200,000 tons.

3. Annual exports:

Now we have exported more than ten countries , such as Asia ,Europe and South America.The average annual export amount is 10 million Yuan , about $1.6 million.

4. Production equipment:

Production and testing equipments are new, complete and automated or semi- automated. Such modern facilities and equipments have provided the fine technical guarantee for the production and testing.

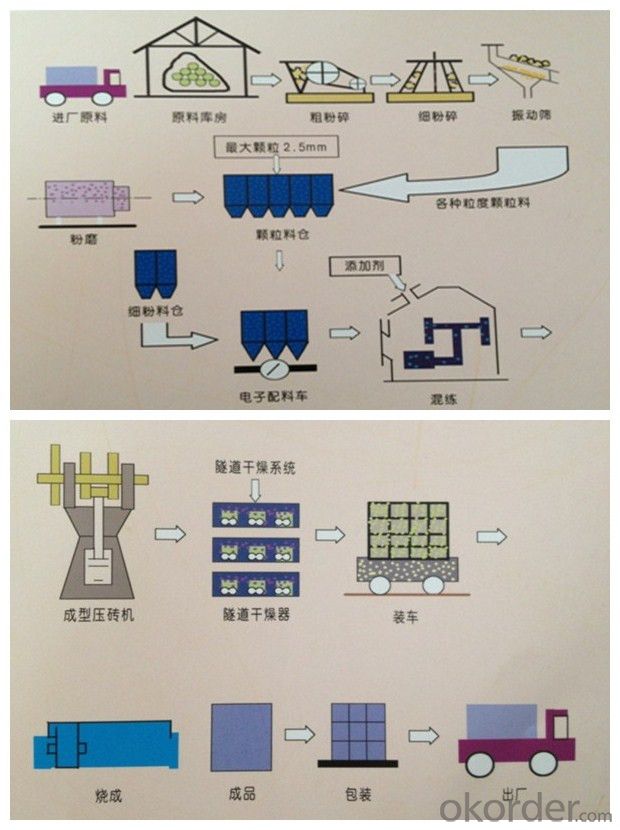

5. Process flowdiagram:

6. Order processing for Refractory Fireclay Brick For Coke Oven:

After the contract is signed, the relevant responsible person tracked production progress, product quality and product packing aperiodically. During the term of contract sent on time with quantity and quality guaranteed.

Why choose us?

1.Competitive price and stable quality to be offered Our refractory materials has export to South America,Australia,Malaysia,UK,etc for many country.

2.Our company provide customer with satisfactory products and services

3.Maybe our price is not the lowest, but our Brick quality is the most trusted

4.we are the real maker and supplier in China, not the middleman.

If you have any questions, we will try our best to satisfy your requirements

Welcome to visit our factory.

- Q: What's the reason of cracks in refractory bricks?

- This is inorganic nonmetallic material

- Q: There are various refractory materials inside many kilns such as refractory brick, what is the role of masonry of these refractory materials?

- When the steel is made, and wear) to complete the purpose of steelmaking, the liquid inside the kiln is melted liquid steel (1550 DEG C), erosion, only the masonry of refractory brick (melt above 1550 DEG C and has a certain strength) can resist various effects of molten steel (melting

- Q: What are 85 bricks, 95 bricks and standard bricks? What are the specifications?

- Clay to clay (including shale, coal gangue powder) as the main raw material, through mud processing, molding, drying and roasting and.

- Q: What kind of refractory brick is suitable for clinker production line of 2,500 tons?

- High alumina brick;

- Q: What are the reasons for the production of waste in the formation of fireclay bricks?

- The reasons for the production of waste when form fireclay bricks: Tile size is unqualified. This is due to the mold installation is not firm, the template transfers when molding; if the amount of material being added fluctuates largely, also can cause the body size changing. Ji Yangon Chi lie charge generation layer containing decyl poke pull and crack. The molding operation does not according to the principle of the light first and the thick later. At the initial pressure, the air doesn't releases, which causes the elastic aftereffect by repressing. Too much mud water, uneven mixture and inequal template all can make the body produce layer crack or crack. Twist. The template is used for too long, the template deforms, so raw brick deforms, the amount of water is too large, brick naturally deforms, causing the body twist. Miss edge and angle. Because of poor plasticity of mud, particles segregate, feeding back corner is not real, the body will appear side missing and angle modulation phenomenon. Bias voltage. Due to the deflection of the die head or the uneveness of mold bottom. Loose。 Due to insufficient feeding amount or insufficient pressure times.

- Q: What are needed to make refractory bricks with micro silica?

- Micro silicon powder is used in mortar and concrete, the ore-smelting electric furnace produces a large amount of strongly volatile gases SiO2 and Si, bridges, seaports. It is ferroalloy. When smelt ferrosilicon and industrial silicon (metallic cilicon), micro silicon power is also called silica fume or condensed silica fume, dam, gas emissions and air condensate and deposit by rapid oxidation, water conservancy, airport runway, tunnel, high-rise buildings, subway, railway, highway and culvert. Application fields of silicon power are cement concrete pavement and mine roadway anchor reinforcement and etc.

- Q: is there any requirement for radioactive materials in refractory materials.

- they all do not cause radiological hazards to the environment, so no requirements! analyze rom the element , magnesia. Do not know if it is useful, but material used by refractory materials, firstly any chemical elements are radioactive, human beings can not close, then, such as silicon dioxide: If it is radioactive. analyze from use, such as bauxite, does not have the use value

- Q: How to use the firebrick to build crucible furnace? How to calculate its furnace's width and depth?

- 1, classify according to the smelting method : Open-hearth?furnace steel: Including carbon and low-alloy steel. According to the different lining material, there are acidic and basic open hearth steel two types. Converter steel: Including carbon and low-alloy steel. According to different positions of blowing oxygen, there are bottom blowing, side blowing and BOF steel three types. Electric furnace steel: Mainly alloy steel. According to the different types of electric furnace and electric arc nail fixed Li modified cool boat to raise spending whale steel, induction furnace...

- Q: What are the physical and chemical properties of refractory bricks

- The thermal shock stability, linear?change?on?reheating, softening temperature under a fixed load, compressive strength under normal strength refractoriness

- Q: The application of wasted refractory bricks

- Refine waste copper, and waste refractory bricks can be used again, shoot two hawks with one arrow

Send your message to us

Fireclay Brick Corundum Brick of Refractory Brick for Steel Industry

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords