Fireclay Brick for Hot Blast Stove

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details for Fireclay Bricks for Hot Blast Stove

| Place of Origin: | China (Mainland) | Shape: | Brick | Material: | superfine burned flint clay/high quality combined clay/ additives |

| Brand Name: |

Packaging & Delivery

| Packaging Details: | manner of packing:Fumigation wooden pallets+paper angle bead+PET strap+stretch film. Wooden pallet size:930*930mm load weight of each pallet:1.5-2.0 tons |

| Delivery Detail: | within 30 days after signing the contract |

Specifications

1.Lower creep

2.To maintain the service life of the kiln

![]()

Such product selected superfine burned flint clay and high quality combined clay as main raw materials, and also selected materials which not easy to shrink and react with minerals at high temperature as additive . After high pressure shaping and high temperature firing , we can get this product.So the product has high strength,high density and low creep rate,and it can better applied to the hot blast furnace,glass furnace and chemical furnaces,etc.

![]()

| Product Item | XX | X | N43 | N42 | N41 | DRN-125 | DRN-120 | DRN-115 | DRN-110 |

| Fe2O3 % | ≥42 | ≥39 | ≥40 | ≥40 | ≥42 | ≥45 | ≥42 | ≥40 | ≥36 |

| Refractoriness °C | ≥1750 | ≥1730 | ≥1730 | ≥1730 | ≥1750 | ||||

| Apparent Porosity % | ≤20 | ≤22 | ≤24 | ≤24 | ≤24 | ≤22(24) | ≤22(24) | ≤22(24) | ≤22(24) |

| Bulk density g/cm3 | ≥2.15 | ≥2.10 | ≥2.10 | ≥2.15 | ≥2.25 | ≥2.25 | ≥2.15 | ≥2.10 | ≥2.10 |

| Cold crushing strength Mpa | ≥35 | ≥35 | ≥30 | ≥30 | ≥30 | ≥40 | ≥35 | ≥30 | ≥25 |

| Refractoriness under load KD,°C | ≥1450 | ≥1400 | ≥1400 | ≥1450 | ≥1450 | ||||

| Permanent Linear Change % | 1400°C×4h ±0.2 | 1400°C×4h ±0.2 | 1300°C×2h ±0.2 | 1350°C×2h ±0.2 | 1400°C×2h ±0.2 | 1400°C×2h -0.4~0.1 | 1350°C×2h -0.4~0.1 | 1300°C×2h -0.5~0.1 | 1300°C×2h -0.5~0.1 |

| creep rate(0.2Mpa*50h)% | 1250°C *(20-50) ≤0.2 | 1200°C *(20-50) ≤0.2 | 1150°C ≤0.8 | 1200°C ≤0.8 | 1250°C ≤0.8 | 1250°C ≤0.8 | 1200°C ≤0.8 | 1150°C ≤0.8 | 1100°C ≤0.8 |

| Application | Regenerative chamber walls and the grid of hot air stove, and the combustion chamber and air chamber of mixed contact tube and various burner brick | ||||||||

![]()

It is widely used in hot blast furnace,glass furnace and chemical furnaces,etc.

![]()

1.Strong professional:

A:The manager of our company has 50 years working experience in refractory product, technology and trading. He has professional function on a various refractory’ s production materials, process control, quality supervision and package delivery.

B: .Company staff are very familiar with refractory and professional knowledge is very good .

C:Company staff are all college culture level.

2. .Annual supply:

Our company has a dozen cooperative production factories which are better in productive technology and quality management. All the factories has passed ISO9001 quality management system certification. And the annual supply of dense shaped and unshaped refractory product is 100,000-200,000 tons.

3. Annual exports:

Now we have exported more than ten countries , such as Asia ,Europe and South America.The average annual export amount is 10 million Yuan , about $1.6 million.

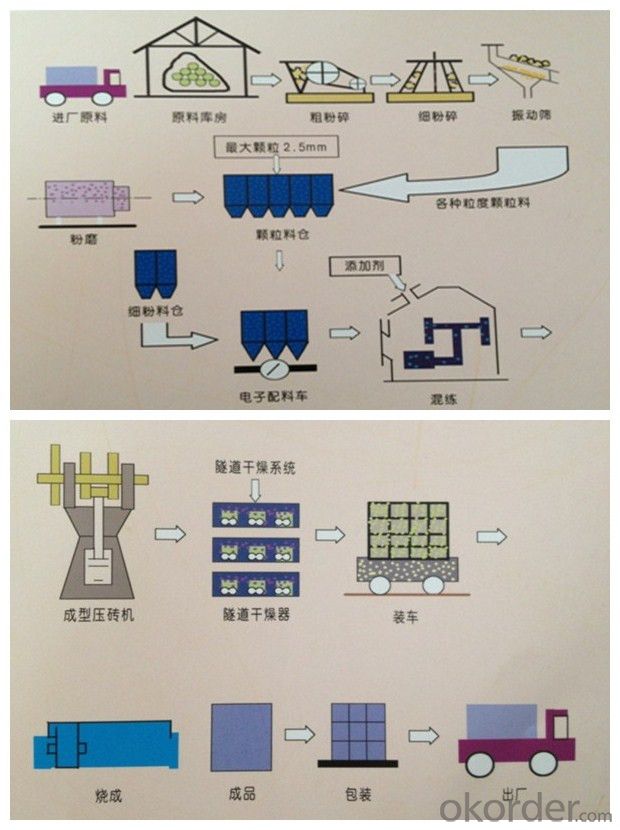

4. Production equipment:

Production and testing equipments are new, complete and automated or semi- automated. Such modern facilities and equipments have provided the fine technical guarantee for the production and testing.

5. Process flowdiagram:

6. Order processing:

After the contract is signed, the relevant responsible person tracked production progress, product quality and product packing aperiodically. During the term of contract sent on time with quantity and quality guaranteed.

Why choose us?

1.Competitive price and stable quality to be offered Our refractory materials has export to South America,Australia,Malaysia,UK,etc for many country.

2.Our company provide customer with satisfactory products and services

3.Maybe our price is not the lowest, but our Brick quality is the most trusted

4.we are the real maker and supplier in China, not the middleman.

If you have any questions, we will try our best to satisfy your requirements

Welcome to visit our factory.

- Q: The furnace refractory bricks are burnt into ash, what material can resist higher temperature than the refractory brick

- refractory bricks, common clay brick, clay brick, high alumina brick and corundum brick

- Q: Are sintered brick concrete bricks?

- Sintered brick: brick made of clay, shale, coal gangue or fly ash, made by molding and roasting at high temperature. Bricks used for masonry, load-bearing and non load bearing walls are collectively called sintered bricks.According to the raw materials, they are divided into sintered clay brick, sintered fly ash brick, sintered coal brick and so on.A sintered brick with a solid or void ratio of less than 25% is called a sintered ordinary brick.The production and use of ordinary clay brick has been in China for more than 3000 years. Nowadays, ordinary clay bricks still dominate the wall materials used in construction projects. Although the ordinary clay brick has many disadvantages, due to its low cost, simple process, design and construction technology is mature and people's inertia and other reasons, the ordinary clay brick for quite a long period of time, especially in rural areas, is still one of the main wall materials.

- Q: What is the refractory brick in silicious model?

- Adding appropriate amount of mineralized agent to promote the transformation of quartz in the body into phosphorus quartz. Smaller coefficient of thermal expansion. Also used in high temperature bearing part of hot blast stove and acid open hearth furnace, refractory materials and ceramic kiln, kiln vault and other load-bearing parts, thermal shock resistance variation. High temperature strength. the glass furnace is burnt in 1430 to 1350 degrees Celsius in the reducing atmosphere. use natural silica as raw materials. True density 2. more than 93% of silica content. generally there is no crystal type transformation above 600 degrees celsius. With acid slag erosion and sediment chamber regenerator performance, soaking furnace, open hearth furnace. there is more crystal type transformation below 600 degrees celsius. mainly used in coking chamer of coke oven and partition of firebox. acid refractory material made of high thermal shock resistance, large volume change, square quartz and a small amount of residual quartz and glass box . Long term use at high temperature without deformation

- Q: How aluminium oxide becomes a entity from the the form of powder (such as a ball, a stone, or a refractory brick)?

- Just like the process of making steamed bun from flour. Ball milling ---in the auxiliary material to make the slurry --- suppress the body --- high temperature calcination

- Q: Can you direct the clay brick walls embryo

- Must not。 Not damp, damp, air tight, poor pressure bearing, bad adhesion between bricks and bricks

- Q: The harm of wet bricks used in refractory bricks

- Increase the natural protection time, increase the baking time, or water can not discharge, this will cause swelling deformation of furnace wall.

- Q: what is the ratio of refractory mortar and refractory bricks, such as how much refractory mortar is needed for a ton of refractory bricks?

- Go to the refractory factory to buy some refractory clay that is of the same material as refractory bricks, generally boiler uses clay refractory mortar.

- Q: What is the difference between the refractory bricks, hand-made bricks and the machine pressure bricks?

- The density of hand-made is not enough, it's light, while the density of machine pressure is high, it's heavy, each has their own benefits

- Q: Why is there cracks in the use of refractory bricks?

- Several reasons for the emergence of cracks: (1) temperature difference stress (2) mechanical stress (3) crystal type change stress

- Q: Why are clay bricks used when buildings are below zero? Frost heaving, water absorption, or something?

- The clay brick has a certain strength, and has better heat insulation and sound insulation performance, and the interior wall of the winter can not appear condensation phenomenon, and the price is low. Although a variety of new wall materials are emerging, clay bricks will still be used as a main material for masonry work in the future

Send your message to us

Fireclay Brick for Hot Blast Stove

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords