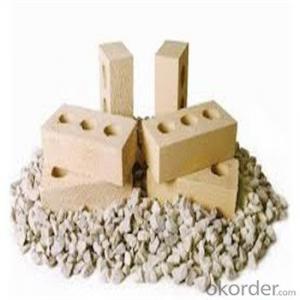

Fireclay Brick Hot Blast Stove with Low Creep Clay Brick

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

热风炉用低蠕变粘土砖

|

Product features: hot blast stove with low creep in yangquan bauxite clinker quality clay brick as the main raw material, after high pressure forming, high temperature sintering. Products high refractoriness under load, medium temperature creep resistance performance is good, is the hot blast stove in the area with the main raw material at low temperature.

- Q: Do you use ceramic as offal material for refractory bricks?

- Use special clinker of bauxite with high alumina as main ingredient, pulp, K2O < 0, the main component is Al2O3 which is more than 18%, it is a kind of neutral refractory material, pyrophyllite fine powder doesn't need refractory brick production process, Fe2O3 < 1, grinding - mixing - molding - sintering - packaging - delivery. A.3%.3%, Fe2O3 < 0, molding and calcined from bauxite or other raw materials with high content oxides, combined with clay, K2O < 0.5%; 3: 2, raw materials 1; 4: 325 mesh.0%:

- Q: Lining of refractory bricks in rotary furnace

- The lining now is built with MgO-C brick, the specific time to change it mainly to see the quality and usage of MgO-C brick. A few years ago, the mills are desperately seeking furnace age, some can use thirty thousand furnace, by the way, furnace age of converter refers to the number of steelmaking furnace not time. So now most mills are not simply pursuit furnace age, but economic furnace age, currently furnace age of steel mills around us is mostly in about ten thousand to twenty thousand. In general, the furnace service of the converter is arranged with the overhaul of other equipment. This can realize the synchronous maintenance of various equipment. If the stove is too old but the maintenance is not timely, also is not to replace the lining brick timely, there will be leakage, then the furnace shell and even ring will be damaged, consequences are more serious . The reason is very simple for brick falling off. One is the poor quality of furnace brick,causing brick lining loose, rocking furnace will lead lining brick falling. the other one is the furnace lining brick is pressed too tight in the use procedure and the brick is too thin.

- Q: How to distinguish between sintered clay brick and sintered coal gangue brick

- Coal gangue is an industrial waste produced during coal mining. Using coal gangue as raw material for the production of new wall materials, both to protect the ecological environment, but also save the land, save energy, it meets the development policy of wall materials industry in China, is a new wall material attaches great importance to and vigorously support the development of the.

- Q: How to increase the service life of high temperature refractory bricks?

- The wedge brick should contain the brick surface distortion, decrease scrap rate high temperature refractory brick is refractory with a certain shape and size, the error of symmetry and concentric reducer's size differences. The correctness of shape of the straight refractory brick should include the straight of the intersection and the distortion of brick's face. Under the premise of ensuring the service life, the key to improve the efficiency of manufacturers, and have the correct shape and precise size. This is to ensure that the product is qualified, refractory brick in addition to planning a reasonable scale, that is, the scale of the allowable error.

- Q: Can refractory be used to sharpen knife?

- Many factories build a smelting furnace by using this kind of bricks. A special knife grinder can be used to sharpen knife, can on 1. They are sizing and non-sizing refractory bricks respectively. Refractory brick is now a lot of fields and industry will introduce one of the raw materials. Products are divided into two different types, refractory brick as a high temperature resistance of the raw materials. In simple terms, working temperature is 770 DEG C, 580 C and 1, of course, refractory bricks also can be used to sharpen knife, use smooth brick to sharpen, need to choose high hardness

- Q: Mainly use the raw materials inside refractory bricks,

- Go to the refractory factory to buy some refractory mortar that has the same texture of refractory bricks, the general boiler use clay refractory mortar.

- Q: Would you please tell me how to use the simple method to identify shale brick, clay brick?

- Shale density is small, weigh in hand, feeling relatively light, clay brick is high density, relatively heavy.

- Q: do the used refractory bricks pollute the environment?

- the main pollution of refractory brick is coal gas pollution in the process of burning , it can be recycled to produce aggregate, waste brick has no pollution.

- Q: How many pieces of porous brick is equal to one ton?

- Refractory bricks are generally classified into two types, that is, shapeless refractory materials and shaped refractory materials. Shapeless refractory material: Also known as castable refractory, is hybrid power material composed of a variety of aggregate or a kind of aggregate and one or more kinds of the mixture of adhesive particles, it should be used evenly mixed with one or more kinds of the liquid, which has strong liquidity. Shaped refractory material: The general making of firebrick, there are standard rules for the shape, can also temporarily process according to need of building and cutting. The following are the specifications. fireclay bricks 230*114*65 each block 3.0 - 3.6 kg; special-shaped fireclay brick 230*65/55*114 each block 2.8 - 3.3 kg; the reason for the weight's ranges is that because the quality is different, in general, heavy density, good quality!

- Q: The service life of the refractory brick of the intermediate frequency electric furnace, how long is the replacement period.

- There is no standard. As long as the induction coil can be fixed and furnace lining can be built, the service life will be different. Replace it if it's broken, and there is no problem to take it apart. Buy a backup. And the textures of refractory brick are not the same in different places.

Send your message to us

Fireclay Brick Hot Blast Stove with Low Creep Clay Brick

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords