Fireclay Brick - Low Thermal Conductivity Refractory Bricks

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 200 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

End Knew Refractory Bricks Low Thermal Conductivity

Brief discription for End Knew Refractory Brick

CMAX End Knew Refractory Brick are classified according to alumina content ranging from 48% to 90%.

CMAX End Knew Refractory Brick are commonly used in blast furnace, hot blast furnace, the roof of electric furnace, teeming ladle, rotary kiln,regenerator, etc.

Brief features for End Knew Refractory Brick

◆Low thermal conductivity

◆Excellent acid and base slagging resistance

◆High refractoriness

◆Excellent thermal shock resistance

◆Excellent mechanical strength

◆Good spalling resistance and wear resistance.

◆Good corrosion resistance.

◆High-temperature creep rate is quite low.

◆Good volume stability at high temperature.

◆Low bulk density, low thermal conductivity, good thermal insulation performance.

Technical data for End Knew Refractory Brick

ITEM | UAL48 | UAL55 | UAL65 | UAL75 | UAL80 | UAL85 | ALP80 |

Refractoriness, ℃ | 1750 | 1770 | 1790 | 1790 | 1810 | 1810 | 1810 |

Apparent Porosity,% | 22 | 22 | 23 | 23 | 20 | 20 | 18 |

C.C.S, Mpa | 39 | 44 | 49 | 53 | 55 | 60 | 100 |

Refractories Under Load (0.2Mpa),℃ | 1420 | 1470 | 1500 | 1520 | 1500 | 1520 | 1550 |

Reheating Linear Change,% | 1450℃x2h 0.1~-0.4 | 1500℃x2h 0.1~-0.4 | 1500℃x2h 0.1~-0.4 | 1500℃x2h 0.1~-0.4 | 1550℃x2h -0.5~+0.5 | 1550℃x2h -0.5~+0.5 | 1550℃x2h -0.5~+0.5 |

Al2O3 Content , % | 48 | 55 | 65 | 75 | 80 | 85 | 82 |

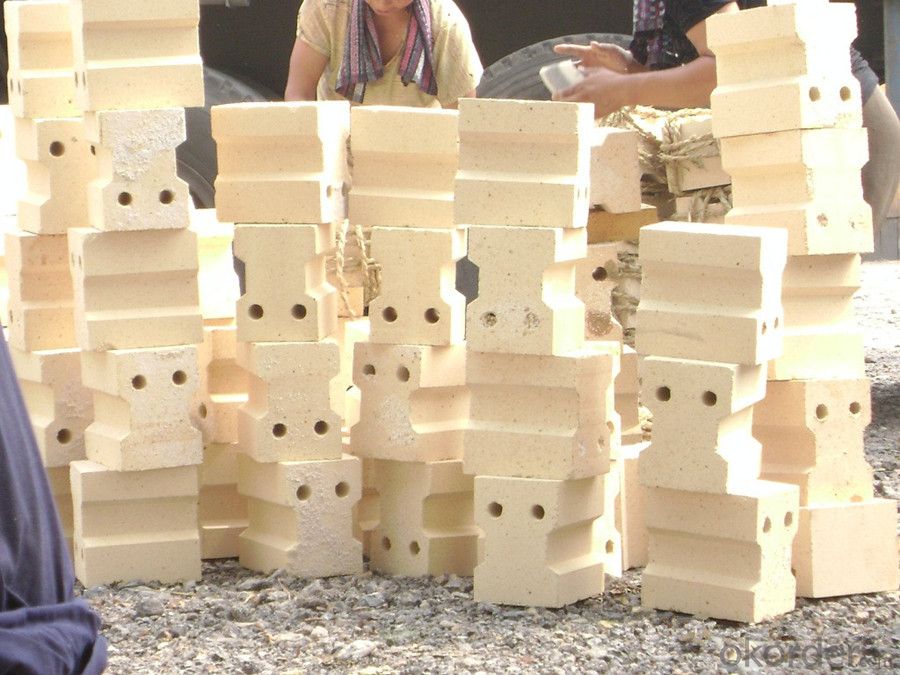

Images/photographs for End Knew Refractory Brick

◆ breif images-different shape for different usage

◆ Packaging for refractory bricks

◆ Producing Equipment for refractory bricks

◆ Testing Mashines for high alumina bricks

FAQ

Q1:Are you a manufacture or trader?

A:Factory+trade(mainly factories,at the same time,we operates other related products).

Q2:Can we visit your factory?

A:Sure,welcome at any time,seeing is believing.

Q3:What's the MOQ of trial order?

A:No limit,We can offer the best suggestions and solutions according to your condition.

Q4:Is your company accept customization?

A:We have own factory and excellent technical team,and we accept OEM service.

Q5:How about your company's certification?

A:ISO9001 and Test Report,also we could apply other necessary certification.

Q6:How to slove the quality problems?

A:If the products are not confirmed to customer samples or have quality problems,our compay will be responsible to make compensation for it.

Q7:Can you offers samples?

A:Of coures,samples are free but freight paid by the buyers.

Q8:What is the service life of your bricks?

A:The service life of different bricks is unlike.It also depends on your using condition and method.

If you have any enquiry,please don't hesitate to contact us,we will provide our best products and services for you!!

- Q: What's the reason of cracks in refractory bricks?

- This is inorganic nonmetallic material

- Q: What material is sk-34 on the refractory brick

- Electric power; refractory bricks, castable refractory, building materials, chemical, glass, ferrous metals and other industries required refractory and insulation materials, all kinds of thermal insulation cotton products, thermal insulation brick, aluminous refractory cement, perlite and other unshaped refractory materials have been the best-selling products

- Q: What is refractory brick? What is refractory clay? ?

- Fire clay refers to the light pouring material, raw materials adopt light porous clinker, bauxite, cenosphere, silicon dioxide ultrafine powder and alumina micropowder. Use calcium aluminate cement CA-80 as binder. Refractory brick is burned from stone powder and clay put in 1300 degrees' kiln

- Q: What is the meaning of special shaped refractory brick material n-2b?

- In fact, there are many kinds of refractory bricks, titanium, high alumina refractory brick, after drying. The mineral composition of the clay brick is mainly kaolinite (Al2O3·2SiO2·2H2O) and 6% ~ 7% impurities (K, etc.). Clay refractory bricks are iron oxide sintered by 50% soft clay and 50% hard clay clinker ingredients according to a certain granularity requirements under the high temperature of 1300 ~ 1400 degrees), perlite

- Q: What is the refractory temperature of refractory bricks?

- First look at the used parts of refractory brick, anti stripping performance, these are the most basic performance factors, the refractory temperature of high alumina brick is 1770 -1790 degree, the refractory temperature of clay brick is 1380-1570 DEG C, record the anti acid corrosion data of refractory bricks, the compressive strength of refractory bricks, at the same time, you should analyze each part of the furnace pH index and sintering temperature of working. When purchasing refractory bricks, you need to pay attention to many factors, high temperature creep property, softening temperature under a fixed load, 6548, volume stability at high temperature. Because the production of the product is affected by the weather and fuel energy, etc.. 186, select the suitable refractory bricks

- Q: Are refractory bricks, burner block and thermal insulation brick the same? Are they the same thing?

- the proportion of raw materials of refractory bricks and thermal insulation bricks. chain of various types of products

- Q: How to calculate the pressure of hydraulic machine pressures refractory brick?

- If it is a plunger type cylinder, the pressure of a cylinder is the cross-sectional area of the piston multiplied by the pressure of the hydraulic system; if it is piston cylinder, that is the inner diameter of the hydraulic cylinder multiplied by the pressure of the hydraulic system. Adopt cm as diameter's unit, a unit of pressure is kilogram force per square centimeter, the calculated result is kilogram which divided by one thousand is ton.

- Q: Blend 12% fireclay and 88% refractory cement. Moderate water and mud are used to pile up firebricks?

- Refractory bricks can irectly be liner. Lightweight mullite brick can be used for relatively longer time. If there is no mullite brick, use mud said above for some time, then continue to use by patching up.

- Q: When using high alumina refractory brick, what are the reasons leading to the decline of the performance of high alumina brick?

- The excess air coefficient is controlled in 1, in order to prevent producing water cracks in the production of high aluminum refractory brick from, control the water absorption of 2 grade clinker of bauxite with high alumina below 4%-5%. 1-1,the water absorption of the tube mill should also be controlled below 6%, and adjust thermotechnical, making the high alumina refractory brick burning be in the stable weak oxidizing atmosphere. should be 2

- Q: Why do some people say that clay brick insulation effect is good, and some people say that bad, in the end what is right?

- The heat preservation effect should be taken away from the heat insulation capacity of the material. The ordinary clay brick has small heat capacity and slow heat conduction, so it is more thermal insulation.

Send your message to us

Fireclay Brick - Low Thermal Conductivity Refractory Bricks

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 200 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords