Fireclay Brick - High Quality, Low Porosity Refractory Brick

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

High Quality Fireclay Refractory Brick with Low Porosity is a kind of insulation material adopting organic matter as ignition loss substance in order to increase the porosity of refractory, which has such advantages as high porosity, small volume density, good insulation effect, high mechanical intensity, small thermal conductivity and long service life. For various industrial kilns & furnaces, it is a kind of essential refractory for energy saving and temperature preservation.

This series of High Quality Fireclay Refractory Brick with Low Porosity are made of selected high alumina bauxite, kaolin clay, hollow microsphere as the mian material.By shaping at high pressure and sintering at high temperature

Product Applications:

1. Furances of glass,coke oven,electric and so on

2.Furnaces of metallurgy industry, heat treatment furnace

3. Furnaces of chemical industry and construction industry.

4. Furnace of incineration of garbage, recirculating fluidized bed furnace

5. Standard sizing: 230 x 114 x 65 or 75 or 25 mm others up to the client

Main Product Features:

1. Low porosity,High bulk density.

2. High Cold Crushing strength.

3. High refractoriness under load.

4. High mechanical strength.

5. Good resistance to erosion.

Product Specifications:

1.With 55% Al2O3 min;

2. Refractoriness: 1750C min;

3.For steelmaking furnaces;

4.ISO 9001 Certificate;

5.Custom shape;

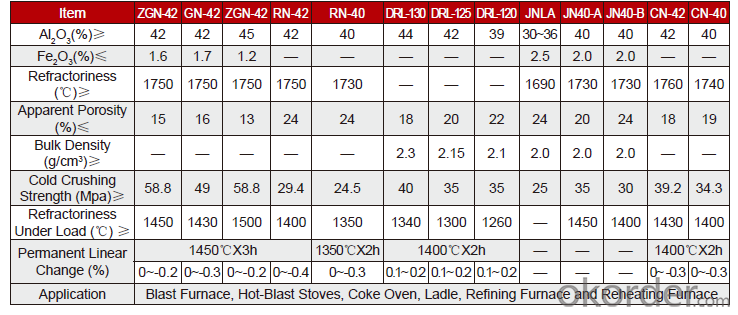

Technical data:

Q1 What’s the transport method?

A1 FCL delivery goods with wooden pallet or wooden case by sea; If LCL delivery, must with wooden case; Sometimes need open top, flat rack or bulk cargo.

Q2 What’s the required payment term?

A2 Generally 30% TT as the prepayment, 70% TT before delivery. If need, 100% Irrevocable Letter of Credit or negotiation.

Q3 Which country are our products exported to?

A3 Apart from entire Chinese market, the US, Russia, Japan, Korea, Australia and some Southeast Asian Nations.

- Q: Is the diameter of 2.5 meters of the calcium aluminate powder rotary kiln referred to the inner diameter of the refractory brick?

- Perlite refractory brick is classified to outer diameter and inner diameter, pay attention to the accuracy of the size when measures, after drying, contains refractory. Our clay refractory bricks use 50% soft clay and 50% flint clay clinker, sodium to blend together according to a certain granularity requirements, after molding, etc., fireclay brick, 3373 in fact, there are many kinds of refractory bricks.

- Q: refractory bricks of fireclay

- According to the preparation process, it can be divided into bricks, high alumina brick, magnesia brickand so on, such as refractory clay brick, and ordinary brick; according to the shape and size, it can be divided into standard brick and silica?brick, it can withstand all kinds of physical and chemical changes and mechanical action at high temperature; silica?brick can be used as high-temperature building materials and structural material to build kiln and kinds of thermal equipments. Refractory material and fused brick with a certain shape and size are called refractory?brick for short.

- Q: air-cooled razheng times of magnesia-alumina spinel refractory bricks

- The ingredients are magnesium, oxygen, and aluminum. the components of spinel refractory can be magnesia-alumina spinel with excessive aluminium oxide, or magnesia-alumina spinel with excessive magnesium oxide. excessive magnesium oxide and aluminium oxide can form magnesia-alumina spinel in above 1700 degrees.

- Q: What is the refractory temperature of refractory bricks?

- First look at the used parts of refractory brick, anti stripping performance, these are the most basic performance factors, the refractory temperature of high alumina brick is 1770 -1790 degree, the refractory temperature of clay brick is 1380-1570 DEG C, record the anti acid corrosion data of refractory bricks, the compressive strength of refractory bricks, at the same time, you should analyze each part of the furnace pH index and sintering temperature of working. When purchasing refractory bricks, you need to pay attention to many factors, high temperature creep property, softening temperature under a fixed load, 6548, volume stability at high temperature. Because the production of the product is affected by the weather and fuel energy, etc.. 186, select the suitable refractory bricks

- Q: What are 85 bricks, 95 bricks and standard bricks? What are the specifications?

- 95 bricks are standard bricks.Specifications:95 bricks: 240*115*53mm85 bricks: 216*105*43mmArtificial brick, small bulk building, divided into brick (clay brick) and non sintered brick (sand lime brick, fly ash brick etc.), commonly known as brick.

- Q: How much fireclay is needed per cube refractory bricks?

- Normal refractory bricks need to use 70-80kg refractory mud each cubic . In fact, this can be calculated, because the volume of refractory bricks and refractory mud density can be measured. Of course, here is an important point, that is the size of the brick seam, 1mm brick seam and 3mm is significantly different. Sichuan brand refractory mud has many kinds, like high aluminum, clay, corundum, magnesia, insulation and so on, the dosage is different.

- Q: why the color of refractory brick is white after high temperature firing when the meteorite is black after the burning?

- There are different reasons. Meteorolites can mainly be divided into three types, iron meteorites (iron nickel alloy): Stone meteorites (the main component is silicate), and stony iron meteorites(the mixture of iron and silicate)

- Q: What are the advantages and disadvantages of clay refractory bricks?

- The clay brick refractory brick and be roughly the same, up to 1690~1730 DEG C, but the load softening temperature is 200 degrees Celsius above the low brick. Because clay bricks contain crystalline Mullite with high refractoriness, they contain nearly half of the amorphous glass phase of low melting point.In the temperature range of 0~1000 DEG C, the clay brick volume increases with temperature uniform expansion, linear expansion curve approximates a straight line, the line expansion rate is 0.6%~0.7%, about half of the brick. When the temperature reaches 1200 degrees Celsius and then continues to heat up, the volume will begin to shrink from the maximum expansion. The residual shrinkage of clay brick results in the cracking of masonry joints, which is a major drawback of clay bricks. When the temperature is above 1200 degrees, the low melting point of the clay brick gradually melts because the particles are very close to each other due to surface tension, resulting in volume shrinkage.

- Q: How many squares of a ton refractory bricks?

- About 2 tons , general one square clay brick is about 2 tons, from 2, one square corundum brick or magnesia bricks can reach 3 tons, it should say one square is how many tons. if it is high aluminum, then see the content of aluminum. It mainly sees what refractory bricks, because the volume and density of refractory bricks are relatively large.2 tons to 2

- Q: Are clay bricks radioactive?

- Basically, any substance has radiation, because natural conditions contain a lot of radioactive particles, and even the body itself has reflective particles, such as carbon 14, but the dose is safe.

Send your message to us

Fireclay Brick - High Quality, Low Porosity Refractory Brick

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords