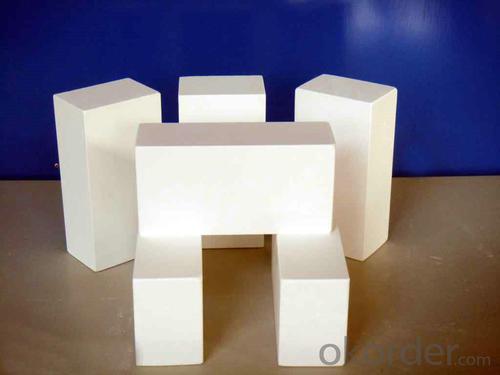

Insulating Fire Brick - High Refractoriness Fire Clay Refractory Heat Insulation Bricks for Heating Furnace

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Thermal Insulation Fire Clay Brick

Refractory brick is a block of refractory ceramic material used in lining furnaces, kilns, fireboxes, and fireplaces.

We provide high quality Refractory Fire Bricks that are used on wide range in the various industries like Cement, Glass and Steel. Refractory Fire Bricks are provided as per the quantity and specifications required by the customers. We provide an extensive range of Refractory Fire Bricks at reasonable prices that depend upon the quantity ordered.

Application

Insulating Fire Brick are used for the lining of converter, alternating current arc furnace, direct Current arc furnace and the ladle slag line, etc.

Company Advantage

(1)Long Insulating Fire Brick manufacture history: 25 years manufacturer

(2)Advanced equipment

(3)Diversification of production standards: ISO ANSI FEPA JIS ASTM

(4)Flexible payment: T/T L/C D/P D/A

(5)Professional marketing team and after-sale service

Insulating Fire Brick main feature:

Equipment

1 unit of Ceramic Abrasive (SG Abrasive) pilot production line

2 units of Compact grain Abrasive pilot production lines

1 unit of high-end coated abrasives (abrasive cloth) production line

2 units of Boron Carbide production lines

3 large flexible crushing and sieving lines for grit production lines

6 units of 5000KVA-10000KVA dumping type electric arc furnaces for Brown Fused Alumina fusion

Q1 What’s the transport method?

A1 FCL delivery goods with wooden pallet or wooden case by sea; If LCL delivery, must with wooden case; Sometimes need open top, flat rack or bulk cargo.

Q2 What’s the required payment term?

A2 Generally 30% TT as the prepayment, 70% TT before delivery. If need, 100% Irrevocable Letter of Credit or negotiation.

Q3 Which country are our products exported to?

A3 Apart from entire Chinese market, the US, Russia, Japan, Korea, Australia and some Southeast Asian Nations.

- Q: Can insulating fire bricks be used for insulation in incinerators?

- Indeed, insulation in incinerators can be achieved by utilizing insulating fire bricks. Constructed from lightweight refractory materials, these bricks possess excellent insulating characteristics, rendering them highly suitable for applications demanding heat containment and energy efficiency, such as incinerators. Due to their low thermal conductivity, these bricks effectively trap and retain heat within the incinerator, thereby preventing heat leakage and enhancing the overall efficiency of the incineration procedure. Furthermore, insulating fire bricks exhibit remarkable resistance to high temperatures and can endure the harsh conditions commonly encountered in incinerators, establishing them as a dependable option for insulation purposes.

- Q: Can insulating fire bricks be painted or coated?

- Insulating fire bricks can be painted or coated, but it is important to use high-temperature paint or coating specifically designed for use with these bricks to ensure durability and fire resistance.

- Q: Are insulating fire bricks resistant to cracking under pressure?

- Insulating fire bricks exhibit resistance to cracking when subjected to pressure. They are specifically engineered to endure elevated temperatures and mechanical strain. Composed of lightweight materials with low thermal conductivity, like ceramic fiber or lightweight aggregates, these bricks maintain their structural integrity even under pressure or thermal expansion. Moreover, insulating fire bricks typically possess a significant alumina content, enhancing their strength and crack resistance. These qualities make them an excellent choice for applications requiring insulation and structural stability, such as furnaces, kilns, and high-temperature industrial processes. Nevertheless, it is crucial to acknowledge that excessive pressure or abrupt temperature changes can still harm insulating fire bricks. Thus, it is essential to adhere to proper installation and maintenance guidelines to ensure their durability and performance.

- Q: Is it possible to repair damaged insulating fire bricks?

- Repairing damaged insulating fire bricks is indeed possible, and the method required will depend on the extent and type of damage. For minor cracks or chips, one can utilize a refractory mortar that is specifically designed to endure high temperatures and create a strong bond. This mortar can effectively fill in the gaps and restore the brick's integrity. However, if a larger section of the brick is damaged or completely missing, it may be necessary to replace the entire brick. In such a scenario, the damaged brick must be cautiously removed, and a new one can be installed with the appropriate refractory mortar. It is crucial to ensure that the repaired or replaced brick adheres to the original specifications and quality to guarantee proper insulation and structural integrity. It is highly recommended to seek advice from a professional or carefully follow the manufacturer's guidelines for the specific repair process.

- Q: Can insulating fire bricks be used in thermal insulation panels?

- Yes, insulating fire bricks can be used in thermal insulation panels. Insulating fire bricks are made from lightweight materials such as clay, alumina, and silica, which have excellent thermal insulation properties. These bricks are designed to withstand high temperatures and provide insulation in various applications, including furnaces, kilns, and industrial equipment. When used in thermal insulation panels, insulating fire bricks can help reduce heat transfer and improve energy efficiency. They can effectively trap and reflect heat, preventing it from escaping or entering the insulated area. This makes them suitable for insulating walls, roofs, and other structures where thermal insulation is required. Moreover, insulating fire bricks are easy to install and can be cut or shaped to fit different spaces and configurations. This flexibility allows for customization and ensures a tight and efficient insulation barrier. It is worth noting that while insulating fire bricks provide excellent thermal insulation, they may not be as effective in sound insulation. Therefore, if soundproofing is also a requirement, additional soundproofing measures may need to be taken. Overall, insulating fire bricks are a reliable choice for thermal insulation panels, offering high insulation performance, durability, and versatility.

- Q: Can insulating fire bricks be used in aluminum furnaces?

- Indeed, aluminum furnaces can utilize insulating fire bricks. These bricks are specifically engineered to possess exceptional thermal insulation characteristics, rendering them ideal for deployment in high-temperature settings like aluminum furnaces. Their capacity to endure the intense heat generated during aluminum melting and their ability to preserve heat within the furnace contribute to enhanced energy efficiency. Moreover, insulating fire bricks offer additional benefits such as shielding against heat dissipation, mitigating the likelihood of overheating, and facilitating a more steady and regulated heating procedure.

- Q: Can insulating fire bricks be used in chimney liners?

- Yes, insulating fire bricks can be used in chimney liners. Insulating fire bricks are designed to withstand high temperatures and provide excellent insulation properties. They are commonly used in applications such as kilns, furnaces, and fireplaces where heat retention is important. When used as chimney liners, insulating fire bricks help to protect the chimney walls from the extreme heat generated by the fire, while also minimizing heat loss. This can improve the efficiency of the chimney and reduce the risk of damage to the surrounding structure. However, it is important to consult with a professional chimney technician or engineer to ensure that the specific type of insulating fire brick being used is suitable for the intended application and meets all relevant safety standards and building codes.

- Q: Can insulating fire bricks be used for pizza ovens?

- Indeed, pizza ovens can make use of insulating fire bricks. These bricks have been specifically crafted to endure extreme heat and offer exceptional insulation, positioning them as an optimal selection for pizza ovens. By possessing low thermal conductivity, insulating fire bricks excel at retaining heat for extended durations, guaranteeing that your pizza is evenly and efficiently cooked. Moreover, their lightweight composition allows for effortless handling and installation in a pizza oven. Ultimately, the utilization of insulating fire bricks within a pizza oven can effectively uphold high temperatures, diminish heat loss, and enhance the overall cooking proficiency.

- Q: Are insulating fire bricks porous?

- Yes, insulating fire bricks are porous. Porosity is a characteristic of insulating fire bricks that allows them to have low thermal conductivity. These bricks are made from ceramic materials and contain a high percentage of tiny air pockets or voids, which trap and slow down the transfer of heat. This porosity also makes the bricks lightweight and resistant to thermal shock. The ability of the insulating fire bricks to retain heat and provide effective insulation is directly linked to their porous structure.

- Q: Do insulating fire bricks require any maintenance?

- Insulating fire bricks, also known as refractory bricks, have been designed to endure high temperatures and offer exceptional insulation properties. One notable advantage of these bricks is their minimal maintenance requirements. These bricks are crafted from specialized materials that exhibit high heat resistance and are not easily prone to cracking or breaking, thereby reducing the need for frequent repairs or replacements. Nevertheless, similar to other materials, insulating fire bricks may accumulate dust or debris over time. To preserve their effectiveness and extend their lifespan, it is recommended to regularly clean them by employing a soft brush or vacuum cleaner to eliminate any loose particles. Additionally, it is crucial to periodically inspect the bricks for any signs of damage, such as cracks or erosion. Promptly addressing any identified issues is vital to prevent further deterioration. In summary, although insulating fire bricks do not demand extensive upkeep, regular cleaning and inspection are essential to ensure their optimal performance and longevity.

Send your message to us

Insulating Fire Brick - High Refractoriness Fire Clay Refractory Heat Insulation Bricks for Heating Furnace

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords