Hygienic Green PVC Conveyor Belts In Food Industry

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hygienic Green PVC Conveyor Belts In Food Industry

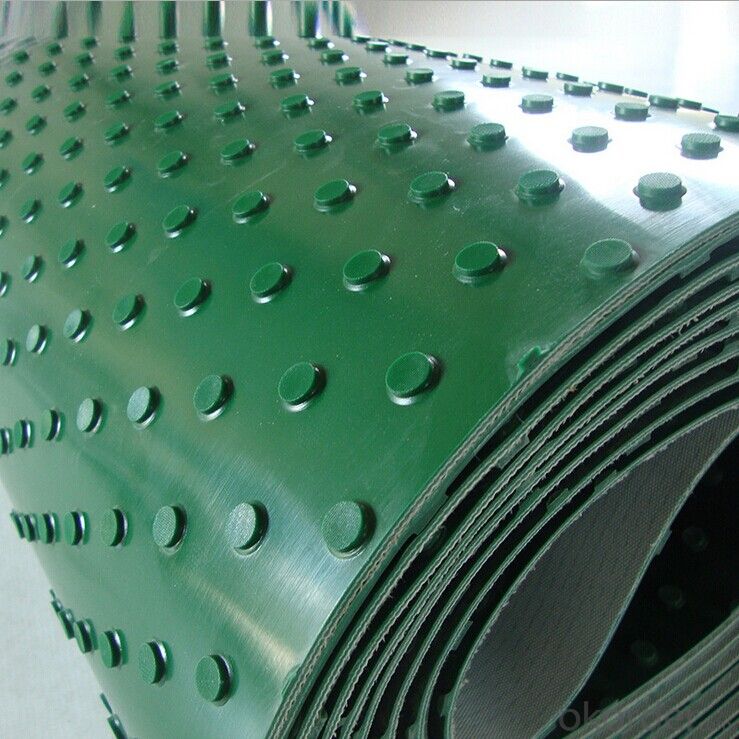

Descriptions of PVC Food Conveyor Belt

We are a highly reputed organization engaged in manufacturing and distribution of hygienic conveyor belts and food conveyor belts. Fabricated from FDA approved polymers, these food conveyor belts are available in high abrasion resistant, anti-static and oil resistant cover grades. Complying with ISO standards, these food belts are dimensionally accurate and available in standard as well as customized specifications.

These hygienic conveyor belts do not stain and odorize the materials to be conveyed and widely used in the food industries for appropriate handling of food stuffs. Our range of hygienic belts is stringently quality checked to ensure that they are free from any kind of defect.

Features of PVC Food Conveyor Belt

Non-conductive

Anti-static

FDA and HACCP standards

Resistant to fats, chemicals, oil fat and abrasion

Various surfaces with high, medium, and low coefficient friction

Dimensional stability

Less noise

Application areas of PVC Food Conveyor Belt

Most popular application include operations in the Sugar IndustryFood Products Organizations mainly use Hygienic Belts for their bulk handling packed materials.

Tea Estates are major users of Hygienic Belts for conveying of various varieties of Green Tea Leaves and forward conveying the same towards Drier Sections, and finally for the packed products.

Pharmaceutical Sectors are major user of Hygienic Belts in their manufacturing units for medicines and packing departments.

Sepcifications of PVC Food Conveyor Belt

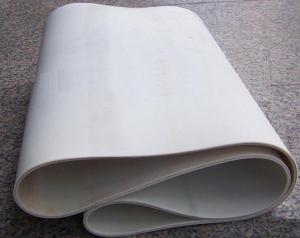

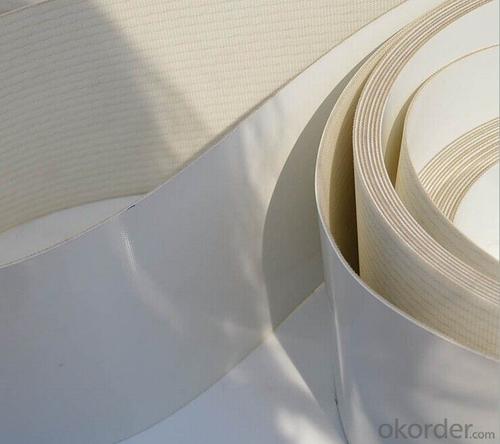

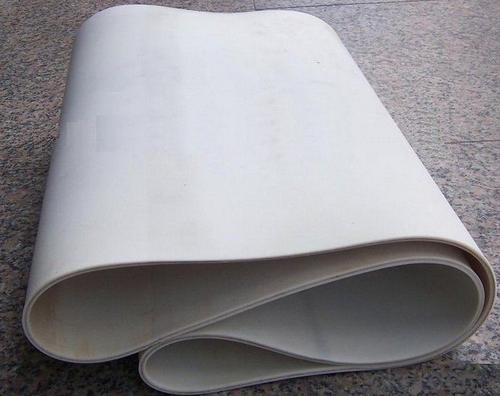

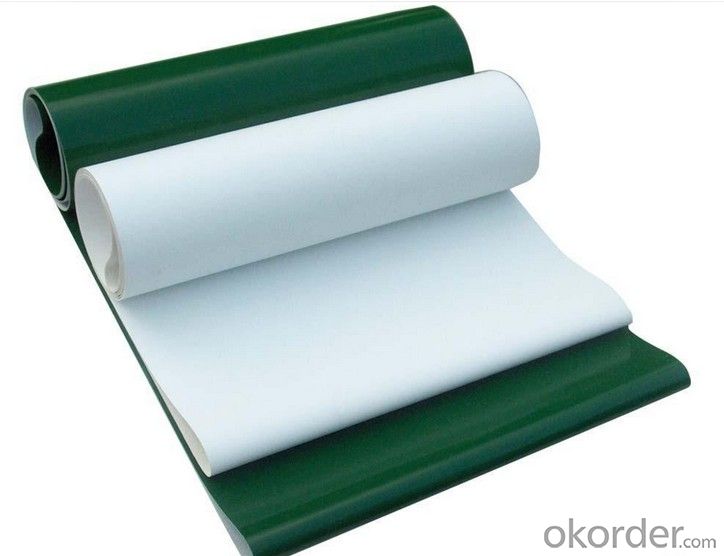

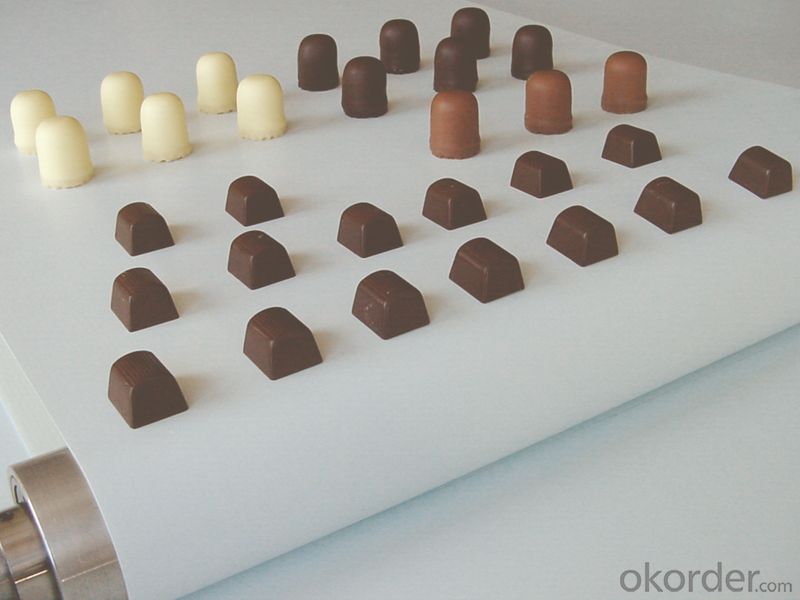

Pictures of PVC Conveyor Belt

RFQ:

Q: Can you do OEM?

A: Yes, we can do OEM products. It's no problem.

Q: How can I get some samples?

A: 1, We are honored to offer you samples. New clients are expected to pay for the courier cost, the samples are free for you, this courier cost charge will be deducted from the payment for formal order.

2, Regarding the courier cost: you can arrange a RPI (remote pick-up) service upon Fedex, UPS, DHL, TNT, etc. to have the samples collected; or inform us your DHL collection account. Then you can pay the freight direct to your local carrier company.

Q: How do you do regarding quality control?

A: Quality is priority? We always attach great importance to quality controlling from the very beginning to the very end:

1).All raw material we used are environmental-friendly;

2).Skilful workers care every details in handling the producing and packing processes;

3).Quality Control Department specially responsible for quality checking in each process.

Q.What are your payment terms?

A: Standard payment terms are 30%T/T,and balance upon the B/L copy .

L/C at sight is acceptable

Other payment terms can be negotiable.

If you want to find more details about the PVC treadmill conveyor belt, you could make an Inquiry in

okorder.com. Okorder.com provides you the products with best price and quality!

- Q: Why is rubber resistant to compression and wear better than metal?

- Rubber crane seen, never seen Iron Hanging

- Q: What advantage does ethylene propylene rubber with three yuan compare to two yuan ethylene propylene rubber?

- Propylene rubber can be divided into two yuan ethylene propylene, three yuan ethylene propylene, modified ethylene propylene and thermoplastic ethylene propylene. Ethylene propylene rubber in olefin copolymerization of ethylene and propylene as binary ethylene propylene rubber; prepared three EPDM with ethylene, propylene and a small amount of non conjugated diene monomer copolymerization. The molecular chain of ethylene propylene rubber, ethylene and propylene monomer showed irregular arrangement, lost the regularity of polyethylene or polypropylene structure, thus becoming the elastomer, because three EPDM diene in the side chain, so the three rubber can be used not only sulfur curing also maintained, various characteristics of two yuan rubber.

- Q: What is rubber material?

- Rubber (Rubber): highly elastic polymeric material with reversible deformation. It is elastic at room temperature and can produce great deformation under very little external force. It can be restored to original state after removing external force. Rubber is completely amorphous polymer, its glass transition temperature (T, g) is low, the molecular weight is often large, more than hundreds of thousands.

- Q: What are the rubber parts for the car?

- Filter rubber parts, cloth (diaphragm), injection pump sealing ring, car frame sealing strip, door seal..... There are many, the car inside the big, small, a lot of rubber products. Watch more and you'll see.

- Q: How to make white rubber products do not yellow or delay yellowing time?

- 1, raw material itself yellow degeneration, for example, NR aging resistance than SBR and BR difference.2, the matching of accelerant system. The accelerator can use DM and M to achieve yellow change 4, but the whole system needs to be adjusted. The use of anti yellowing enhancers such as two dithiocarbamate on yellow Bianyou benefits, but at the expense of great property and operation. The faster the sulfidation rate, the less the chance of breaking the chain, and the aging degree is restrained. But at the same time sacrificing the comprehensive nature. The cross-linking bonds generated by rapid vulcanization and slow vulcanization are different. For example, tension, tear and so on, are greatly affected. But the elasticity brittleness will increase.

- Q: Comparison of physical properties of HNBR rubber material with other rubber materials

- HNBR has a high temperature resistance of 130~180 degrees, cold resistance of -55 ~ -38 degrees, and good mechanical properties, compared with other polymers, can meet the requirements of the automotive industry. HNBR with ZnO/ methacrylate (MAA) can be used to make V-belt, triangular V-belt, multi base rubber, vibration isolator and so on. It can also prepare sealing ring, sealing element, heat resisting tube and so on. In oil drilling, rubber products are required to withstand high temperature, high pressure, acid, amines, H2S, CO2, CH4 and other tests of steam. The products prepared by HNBR can be acid resistant, oil resistant and solvent resistant. With the ZnO/MAA HNBR reinforcement can be used for the production of drilling mud pump piston and protection box. In addition, the beating method HNBR can be used as a sealing washer washer made of paper oil industry and automobile industry. HNBR heat and radiation resistance properties than silicon rubber, fluorine rubber, poly four vinyl chloride is better, suitable for all kinds of rubber seals for power station, is also used as a hydraulic pipe, hydraulic seals, power station for cable sheath, can also be used for printing and fabric roller, weapons components and aerospace seals, cover, fuel capsule; HNBR latex can be used as a surface coating (painting), textile, paper, leather, metal, ceramic fiber, non-woven adhesive, and foam rubber, latex impregnated products etc.. In addition, with ZnO/MAA, peroxide and high wear furnace HNBR, its comprehensive performance is better than ordinary HNBR.

- Q: I do rubber products, I would like to ask what metal accessories are rubber products, the specific name is what, good, then points

- Silica gel tube, other rubber tube, clip fabric hose, braided hose, oil resistant hose, special hose, winding hose, industrial rubber, rubber products, insulating sleeve

- Q: What kind of rubber does TPE belong to?

- TPE does not belong to rubber.Although TPE has a tensile resilience similar to that of ordinary rubber, TPE is thermoplastic and rubber is thermosetting. Rubber needs cross-linking. It can not be reprocessed after molding. TPE can be processed repeatedly.

- Q: Which kind of rubber has the best wear resistance?

- Main useNitrile rubber is mainly used for the production of oil products, such as the oil pipe, tape, rubber diaphragm and large oil sac, commonly used in the production of various types of oil resistant molded products, such as O ring, oil seal, rubber bowl, diaphragm, valve, bellows, is also used to make blankets and wear parts.

- Q: How is the temperature range of rubber determined?

- Vulcanized rubber is related to vulcanizing reagents, fillers and so on! The low temperature limit generally refers to the glass transition temperature. Of course, the finished rubber also has the physical properties required by the customer for the low temperature dynamic work!

Send your message to us

Hygienic Green PVC Conveyor Belts In Food Industry

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords