Laminated Aluminum Steel Sheets - Prepainted Galvalume for Sandwich Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

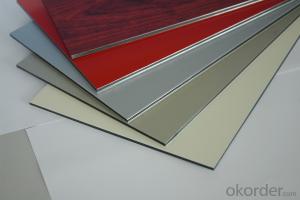

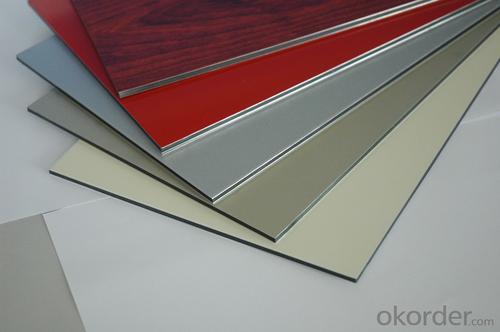

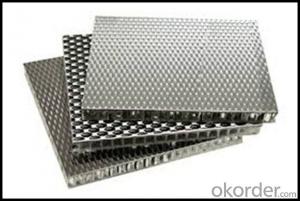

Structure of Aluminium Prepainted Galvalume for Sandwich Pannel Description:

Coated aluminum coil/sheet are of a wide range of colors, which gives wonderful appearance no matter in residential and commercial constructions of great exhibition centers.

The coated aluminum coil/sheet have been widely used in the fields of construction and decoration( garage doors, ceiling etc.), electronic appliances, lighting decoration, air-condition air pipes, sandwich panels and drainages etc.

Main Features of the Aluminium Prepainted Galvalume for Sandwich Pannel:

1) High flexibility

2) Impact resistance

3) Excellent weather-proof durability

4) Anti-ultraviolet

5) High erosion resist

Images of Aluminium Prepainted Galvalume for Sandwich Pannel:

Aluminium Prepainted Galvalume for Sandwich PannelSpecification:

Alloy | A1100,A3003,A1050,A8011 etc |

Temper | H16,H18,H24 |

Thickness | From 0.024mm to 1.2mm |

Width | Standard width:1240mm |

Special width:1300mm,1520mm,1570mm,1595mm | |

Diameter | Standard dia:1200mm |

Interior dia:150mm,405mm,505mm | |

Weight | 2.5 T/coil,3.0 T/coil |

Coating | PE, PVDF, AC |

Surface | Embossed, mill finish, coated |

Color | AS to code RAL |

Gloss | 10-90%(EN ISO-2813:1994) |

Coating Thickness | PE: more than 18 micron |

PVDF: more than 25 micron | |

Coating Hardness (pencil resistance) | More than 2h |

Coating adhesion | 5J(EN ISO-2409:1994) |

Impact Resistance | No peeling or cracking(50 kg/cm,ASTMD-2794:1993) |

Flexibility (T-bend) | 2T |

MEK resistance | More than 100 |

FAQ:

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 2000tons.

b. Now which countries do you export your goods?

---Now we export to South East Asia,Africa, North America,South America ect.

- Q: What is the difference between aluminium plate 5A05 and 5A06?

- The aluminum plate doesn't have this material. Have you made a mistake?Give you a full one,1, pure aluminum: Material: 1050/1060/1070/1100/ 1200/ thickness: 0.1---20mm width: 800---2200mm2, alloy aluminum: Material: 2A21/3003/5052/5083/6061/6082 /8011 thickness: 0.5---260mm width: 800---2800mm3 curtain wall Kaiping aluminum plate: Material: 1060/1100 thickness 0.95, 1.35, 1.85, 2.35, 2.7, 2.85mm, width 0.8---1.5m

- Q: Could induction heating fuenace be packaged with aluminum foil as insulation material?

- Aluminum foil can’t be used for heat retaining, it’s unsafe and hasn’t good efficiency. In this case, advice you use refractory cement to knot the coil and connect porcelain tube in the middle. It will Largely reduce the energy consumption produced by heat radiation.

- Q: Can aluminum sheets be used for decorative ceiling panels?

- Aluminum sheets are indeed suitable for decorative ceiling panels. The versatility of aluminum as a material offers numerous advantages for this purpose. Its lightweight nature, durability, and resistance to corrosion make it an ideal choice for long-lasting use. Moreover, aluminum sheets can be easily molded and shaped into various designs, patterns, and textures, allowing for visually appealing ceiling panels. To enhance their aesthetic appeal and match the desired decor style, these panels can be finished with different coatings or finishes. Additionally, aluminum is a sustainable and eco-friendly material that can be recycled, making it an excellent option for those who prioritize environmental consciousness. In summary, the versatility, durability, and aesthetic potential of aluminum sheets make them an outstanding choice for decorative ceiling panels.

- Q: Can aluminum sheets be formed into seamless tubes or pipes?

- Seamless tubes or pipes can indeed be created from aluminum sheets. This is commonly achieved by employing a technique known as extrusion, in which the aluminum sheet is heated and compelled through a die to acquire the desired form. The extrusion process enables the production of seamless tubes or pipes that possess uniform dimensions and a polished surface. Due to its exceptional versatility and malleability, aluminum is an ideal material for numerous applications necessitating lightweight and corrosion-resistant tubing.

- Q: is aluminum foil spacer poisonous after heating?

- many baked food will use aluminum foil.

- Q: Can aluminum sheets be used for battery casings?

- Indeed, battery casings can be made using aluminum sheets. Aluminum, a metal that is both lightweight and durable, possesses superb corrosion resistance, making it an ideal option for battery casings. Moreover, aluminum exhibits excellent electrical conductivity, a crucial factor for optimizing battery efficiency. Furthermore, aluminum can be easily molded and formed into diverse shapes and sizes, granting flexibility in battery casing fabrication. In conclusion, due to its advantageous characteristics, aluminum sheets are widely employed in battery casing production.

- Q: Can aluminum sheets be polished?

- Yes, aluminum sheets can be polished. Polishing aluminum sheets involves smoothing the surface and creating a reflective finish using abrasive materials or polishing compounds.

- Q: This question asks about the various types of coatings that can be applied to aluminum sheets.

- <p>Aluminum sheets can be coated with various materials to enhance their properties such as corrosion resistance, appearance, and durability. Some common types of coatings include: 1. Anodizing, which creates a protective oxide layer on the surface. 2. Powder coating, a dry coating that is electrostatically applied and then cured at high temperatures. 3. Paint coating, which can be either liquid or powder-based and provides a decorative and protective layer. 4. Vinyl coating, which is a plastic coating applied for a smooth, matte finish. 5. Electrolytic coating, which involves depositing a thin layer of metal onto the aluminum surface. 6. Hot-dip coating, where aluminum is coated with a layer of zinc or other metals by dipping it into a molten bath. Each type of coating serves different purposes and has unique characteristics.</p>

- Q: How does my world Pocket Monster mod aluminum plate synthesize?

- To dig the Elven blood machine at the Pocket Monster Center

- Q: Hi guys. I was just wondering if you can give me some tips or information on what you know about painting on metal. The metal that is of concern is aluminium and I would like to put a stencil over this aluminium and just blast it with a can of krylon. Of course...this aluminium piece is actually part of the housing for my cell phone so doing it like this would probably not be right and the paint would probably wear out. I am mainly interested in finding out what kind of paint to use, what tools i need, and how to achieve an extremely! durable! matte finish because this phone is thrown around and going in and out of my pocket the paint will have to withstand getting rubbed down everyday by my pockets.That was a very long question, thanks for bearing with me and thanks in advance for those who provided me with an answer/thought. THANKS!

- Krylon is a very tough metal medium and the newer product they have at wal-mart in the paint section is fantastic. I don't know about rustoleum, other than another brand, but you could use a coat of polyutherine matte varnish. You can get this at wal-mart in the paint section or a hardware store. It will seal anything.

Send your message to us

Laminated Aluminum Steel Sheets - Prepainted Galvalume for Sandwich Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords