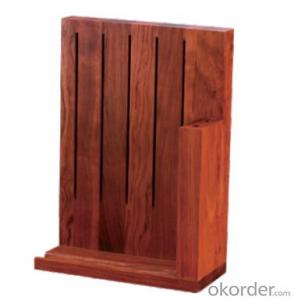

knife seat,F-KB087 Carbonized bamboo knife seat,your best choice

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

product name:rubber wood knife seat

material:rubber wood

N.W.:0.568kg

MEAS:24.5*22.11cm

Product advantage:

How does the bamboo product carbonize?Firstly,put the bamboo or bamboo bag into the high-pressure carbonized boiler of 200 degrees - 300 degrees for vapor carbonization,and after high temperature and high pressure, so that form a hard carbide particles layer on the surface.At the same time,the bamboo itself will be more harder.

The advantage of carbonized bamboo knife seat:after carbonize,hard carbide particles will form a environment not easy living for bacteria on the surface of bamboo product to achieve the antibacterial effect.At the same time, because after carbonization the bamboo will be more hard than ordinary paper products, preventing wearing and bamboo thorn problem.

Carbonized bamboo knife seat quantity:

Safety, health, bright color,durable,the everyday necessary good products

Anti-mildew change,anti moth

Environmental protection,no crack,no decay

- Q: How to install CNC machine tool

- Vertical turret mounting(1) open the guide strip and press plate on the cutter holder, clean the guide rail and the processing surface, check the guide rail surface should be intact without rust.(2) the left and right vertical turret respectively with lifting beam, with oil on the rail surface, the gear transmission is to mobile tool beam assembly hole, mounted on the plate, strip, slide clearance adjustment.(3) the vertical shaft of the vertical cutter head is installed, and the compression member of the balance hammer is removed, so that the counterweight is balanced.

- Q: How to distinguish the CNC lathe turret and turret turret after that car, belonging to the front tool or tool? Before the turret is cylindrical with G42 or inner circle?

- The turret of the numerical control lathe is the front knife holder in the operator's side. The common lathe is the rear cutter. When the tool head, the G42 tip radius compensation right bias in the car when the hole, when the car is round with G41.

- Q: CNC lathe turret in place how to do

- Tool change:1, the machine tool holder after the knife, the knife is a mechanical problem, the center of high deviation2 turret Rihall element, proximity switch, encoder, damage. Or poor contact, or 24 volt supply knife is not normal.3 according to the different types of tool holder, check the tool manual, with the electrical schematic diagram and ladder diagram to find out the cause of the fault.

- Q: In front of the turret with rear turret in the car to count the G41G42 cutter compensation when there is no difference?

- The operator is standing in front of the numerical control lathe, the cutter head is located between the main shaft and the operator. When the tool spindle is rotating, the tool head is turned upward, and the cutter head is rotating. The front and rear turret turret programming is the same, clockwise and counterclockwise circular interpolation G02 interpolation G03 direction is right according to the Descartes coordinate system, first determine the positive direction of the Y axis, and then from the positive direction of Y in the negative direction seems to determine the positive direction of the X axis, and then determine the G02 and G03 in the direction of the XZ plane can be, in front of the turret Y positive axis down, rear turret Y positive axis upward. No matter what the system is the same, if you in the right direction according to the right to see Descartes coordinate system can determine G02 and G03 in the front and rear turret style the same, the Y axis is a virtual axis lathe, there is practically no Y axis.

- Q: Tool holder S solution

- Vertical typeThe wheel frame, in fact, is a parallel steel frame structure.Than S, there are many advantages.For example, solid, DIY, modification, etc.

- Q: What is the difference between the tool holder of the CNC machine tool and the horizontal lathe

- Lathe is generally more than a knife, a good point of the lathe is also used 8 knife turret, machining center with a knife library

- Q: What is the difference between numerical control tool holder and power tool holder

- Seems to be a thing. The knife of CNC machine tool CNC turret should refers to the (for the realization of automatic tool change in the process), can be divided knife straight row knife, disc knife, knife and other bamboo hat.

- Q: The difference between the tool holder and the electric tool holder

- The difference is that there is only one knife library, is T0101, if you want to use a few knives, that is, 02 or more behind the T01 can do it!To row knife knife, if you want to T0101 the knife, you put a knife to a knife or light near the end, directly in the 01 hit patch which according to the Z0 input, the outer circle you have, what is the volume of just the tool compensation which according to the X.. Input, you want to second third or more knife is the same; but you must take the time to fill in to lose in the digital knife to a knife, or otherwise useless.The tool holder is four knife library, you want to use a knife is T0101 or T0202.T0303.T0404. The two is not mixed with the. Hope to help you.

- Q: The first reason is that the cutter shaft of the motor shaft is broken for a shaft / how long it will not be able to die!

- Adjust the parameters, the tool change time and lock time, try!

- Q: What are the advantages and disadvantages of CNC lathe turret

- CNC lathe in the use of the process, the common fault of the tool holder, spindle, thread processing class, the system display class, drive class, communications and other failures, and the tool holder fault occupies a large proportion. After the failure of the machine can not be used temporarily, resulting in a waste of manpower and material resources in time. If we can do some basic maintenance, we can save costs, save time and create a certain economic benefits.

Send your message to us

knife seat,F-KB087 Carbonized bamboo knife seat,your best choice

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords