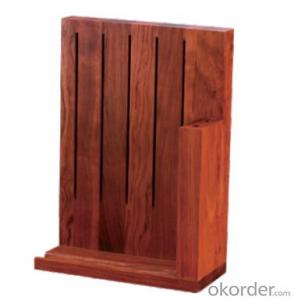

F-KB086 Carbonized bamboo knife seat,your best choice

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

product name:rubber wood knife seat

material:Carbonized bamboo

N.W.:1.218kg

MEAS:23*20*10cm

Product advantage:

How does the bamboo product carbonize?Firstly,put the bamboo or bamboo bag into the high-pressure carbonized boiler of 200 degrees - 300 degrees for vapor carbonization.

And after high temperature and high pressure, so that form a hard carbide particles layer on the surface.At the same time,the bamboo itself will be more harder.

The advantage of carbonized bamboo knife seat:after carbonize,hard carbide particles will form a environment not easy living for bacteria on the surface of bamboo product to achieve the antibacterial effect.

At the same time, because after carbonization the bamboo will be more hard than ordinary paper products, preventing wearing and bamboo thorn problem.

Carbonized bamboo knife seat quantity:

Safety, health, bright color,durable,the everyday necessary good products

Anti-mildew change,anti moth

Environmental protection,no crack,no decay

- Q: The system is a wide number of 980TDb, lathe is the Yunnan machine tool factory. Whether it is a manual tool change or MDI way to enter the specified number of knives, the tool holder always turn around, until the emergence of PLC alarm 1000 change knife time is too long, A0000.0 knife can not reach the designated position. What the problem ah, I did not move the parameters of the machine, ah, this morning is good, work in the afternoon a boot on this.Back to the origin of the machine are abnormal, and can not return to the origin of the machine. Press the corresponding button after the machine does not respond, will not act. It's normal in the morning.

- Note: it is important to ensure the lubrication system

- Q: Numerical control lathe tool holder is a tool to change what is the fault

- It should be blocked to form the motor overload, the method is verified about CNC lathe turret and motor out, if not the normal disc worm that is stuck to the machine, can be disassembled in accordance with the instructions of disassembly tool, check the internal parts to see if there is deformation coupling and so on because, in many cases is mechanical clamping due to collision deformation.CNC lathe: CNC lathe, also known as the CNC lathe, that is, computer numerical control lathe, is China's largest use, the most extensive coverage of a CNC machine tools, accounting for about 25% of the total number of CNC machine tools. A set of mechanical, electrical, hydraulic, pneumatic, microelectronics and information technology as one of the integrated mechanical and electrical products. Has the advantages of high precision, high efficiency, high automation and high flexibility for manufacturing equipment in machine tools.

- Q: CNC lathe turret in place how to do

- This is a bad inquiry, a change to solve the problem

- Q: Why is the number 980 CNC lathe turret always turn and then alarm

- What is the alarm? If the information is only in the parameters of the interface will not be canceled after the pop-up bar. If the alarm is always there must be an alarm number.

- Q: How to use the left side of the knife knife thread?

- With the right angle, X write positive, and with the left deflection angle, the value of X to write negative. Because the coordinates are opposite

- Q: How to do the slide shoe

- Nails can be used as follows.Use a hammer to hammer the bigger one in the mouth, then screw it.In addition, there is a special tool for dealing with sliding wire. You can break a nail.Knife slide wire no way, can only change the tool holder. Even if the wire tapping to do the thread, the diameter is not the same as the original

- Q: What is the difference between the NC lathe and the tool post

- Also, the most important thing is to look at the direction of the knife, there are positive and reverse difference, that is, M3 and M4

- Q: However, No. 2, No. 3, the normal use of potential energy on the knife No. 4 can not be normal use of the rotation has not stopped on the 1.

- 1-2-3 knife is normal? Can't you find the knife on the number four? The 4 line may be broken or bad contact!

- Q: What are the parts of the lathe and tool holder

- A lathe is a device; a tool holder is a lathe.

- Q: 1, CNC horizontal lathe tool holder with front and rear respectively. CNC vertical lathe tool holder how to classify?2, no matter front or rear CNC lathe, cutter movement from right to left (along the Z axis) with G42 compensation?

- In the tip of the compensation bar to enter the radius of the tip of the knife is good, of course, we must first know the radius of the tip of the nose,

Send your message to us

F-KB086 Carbonized bamboo knife seat,your best choice

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches