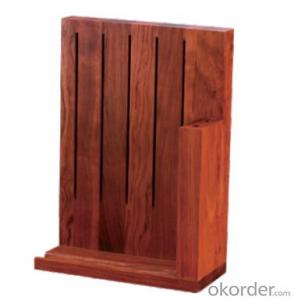

knife seat,F-KB081 Carbonized bamboo knife seat,your best choice

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

product name:rubber wood knife seat

material:carbonized bamboo

N.W.:0.716kg

MEAS:25*28*13cm

Product advantage:

How does the bamboo product carbonize?Firstly,put the bamboo or bamboo bag into the high-pressure carbonized boiler of 200 degrees - 300 degrees for vapor carbonization,and after high temperature and high pressure, so that form a hard carbide particles layer on the surface.In the same time,the bamboo itself will be more harder.

The advantage of carbonized bamboo knife seat:after carbonize,hard carbide particles will form a environment not easy living for bacteria on the surface of bamboo product to achieve the antibacterial effect.At the same time, because after carbonization the bamboo will be more hard than ordinary paper products, preventing wearing and bamboo thorn problem.

Carbonized bamboo knife seat quantity:

Safety, health, bright color,durable,the everyday necessary good products

Anti-mildew change,anti moth

Environmental protection,no crack,no decay

Primary Competitive Advantages:

Brand-name Parts Country of Origin

Distributorships Offered Experienced Staff

Form A Green Product

Guarantee/Warranty International Approvals

Packaging Price

Product Features Product Performance

Prompt Delivery

Main Export Markets:

Eastern Europe North America

Mid East/Africa Central/South America

Asia Western Europe

Australasia

- Q: Numerical control lathe tool holder is a tool to change what is the fault

- It should have been broken. It's the white plastic ring. Seems to forget what

- Q: How to distinguish the CNC lathe turret and turret turret after that car, belonging to the front tool or tool? Before the turret is cylindrical with G42 or inner circle?

- Whether NC or normal car, a knife in the side is the pre processor, or post, either rear or front, when processing with radius compensation are determined according to the post, the outer circle with G42, G41 in the hole.

- Q: Who has any good method or fixture drawings and pictures for younger brother to learn ah, do not be grateful, want to do, but I have not seen this thing, the idea does not come out

- Very simple, find a square on the grinder grinding angle four straight, like a knife, much bit big hole, the drill bit into a wire on the bit in the next attack on the line, but straight shank drill.

- Q: In front of the turret with rear turret in the car to count the G41G42 cutter compensation when there is no difference?

- The turret of the numerical control lathe is the front knife holder in the operator's side.The common lathe is the rear cutter.When the tool head, the G42 tip radius compensation right bias in the car when the hole, when the car is round with G41.

- Q: CNC turret can be turned into 45 degrees ah? Can you turn counterclockwise?

- 8 position of the numerical control turret, each turn 1 knife is 45 degrees, can be positive and negative (that is, clockwise and counterclockwise rotation)

- Q: What are the parts of the lathe and tool holder

- A lathe is a device; a tool holder is a lathe.

- Q: Is the plastic knife holder of roller skate good or metal knife holder good?

- Metal turret. Should not be used to, we do not play a long time just go up the leg will be very tired. Shoes foot is tight, a little sluggish flow of feeling. Good fun.

- Q: Numerical control lathe tool holder does not match the system cutter number

- The turret operation is not in place (sometimes appear suddenly, the mid position stay) is mainly due to signaling disc contact and elastic sheet contact displacement, namely the cutter disc position signal to a fixed offset bakelite. At this point, it should be adjusted to the contact position of the contact plate and the elastic plate. If you still can not rule out the fault, it is possible to send the disk clamping nut loose, resulting in the location of mobile.

- Q: 1, CNC horizontal lathe tool holder with front and rear respectively. CNC vertical lathe tool holder how to classify?2, no matter front or rear CNC lathe, cutter movement from right to left (along the Z axis) with G42 compensation?

- 1: CNC vertical lathe no front and rear points, and it is different in general, the sleeper, knife in the right side of the center of the spindle, convenient use and debugging. The car generally have two knife, one is the vertical tool holder, but also often use the tool holder (according to different parts processing), can move up and down about (X, Z). One is the side of the knife, the general processing parts of the outer circle and the vertical knife can not be processed.2: personal understanding, CNC lathe general rarely used tool about compensation instruction, but to consider the nose arc, arc may result in the instruction of size and the size of the actual processing gap, but it can be in the compensation of tool interface, realize the compensation problem of the arc.

- Q: CNC lathe tool holder clamping bit how to clip

- The drill chuck can be arranged on the knife tower only by processing a drill handle, and a straight shank drill is arranged on the drill chuck.

Send your message to us

knife seat,F-KB081 Carbonized bamboo knife seat,your best choice

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords