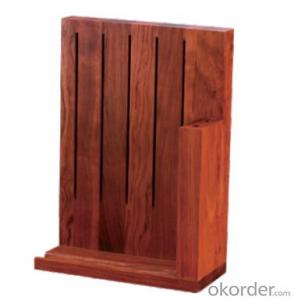

knife seat,F-KB083 Carbonized bamboo knife seat,your best choice

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

product name:rubber wood knife seat

material:Carbonized bamboo

N.W.:1.286kg

MEAS:22*16.5*15cm

Product advantage:

How does the bamboo product carbonize?Firstly,put the bamboo or bamboo bag into the high-pressure carbonized boiler of 200 degrees - 300 degrees for vapor carbonization.

And after high temperature and high pressure, so that form a hard carbide particles layer on the surface.At the same time,the bamboo itself will be more harder.

The advantage of carbonized bamboo knife seat:after carbonize,hard carbide particles will form a environment not easy living for bacteria on the surface of bamboo product to achieve the antibacterial effect.

At the same time, because after carbonization the bamboo will be more hard than ordinary paper products, preventing wearing and bamboo thorn problem.

Carbonized bamboo knife seat quantity:

Safety, health, bright color,durable,the everyday necessary good products

Anti-mildew change,anti moth

Environmental protection,no crack,no decay

- Q: How to distinguish the CNC lathe turret and turret turret after that car, belonging to the front tool or tool? Before the turret is cylindrical with G42 or inner circle?

- Whether NC or normal car, a knife in the side is the pre processor, or post, either rear or front, when processing with radius compensation are determined according to the post, the outer circle with G42, G41 in the hole.

- Q: Why is the number 980 CNC lathe turret always turn and then alarm

- What is the alarm? If the information is only in the parameters of the interface will not be canceled after the pop-up bar. If the alarm is always there must be an alarm number.

- Q: The development trend of numerical control tool holder

- Vertical tool holder has four, six stations in the form of two, mainly for simple CNC lathe; horizontal tool holder has a position of eight, ten, twelve, can be positive and opposite direction rotation, the nearest election knife for the full function CNC lathe. In addition, the horizontal tool holder is provided with a hydraulic tool holder and a servo driving tool holder.

- Q: What are the parts of the lathe and tool holder

- A lathe is a device; a tool holder is a lathe.

- Q: The difference between the tool holder and the electric tool holder

- Methods with 980 for example: the first knife in the knife up one page T0010 for the input of X0Z0 cutter compensation in T0020 dabbler cutter compensation second page cutter compensation input X0Z0, the rest of the line.

- Q: CNC lathe tool holder clamping bit how to clip

- The drill chuck can be arranged on the knife tower only by processing a drill handle, and a straight shank drill is arranged on the drill chuck.

- Q: For what parts of the process, what is the difference between the installation

- When turning slender shafts, the central frame can be used to increase the rigidity of the workpieceWith the tool holder fixed on the bed saddle, there are generally two supporting claws, with the tool holder can follow the movement of the tool to offset radial cutting can increase the stiffness of the workpiece, reduce deformation. So as to improve the shape precision and reduce the surface roughness.

- Q: What is the material of the cutting tool

- One, the tool holder commonly used materials:High carbon steel is often referred to as tool steel, mainly used in the manufacture of cutting tools, etc.. The characteristics of its carbon content from 0.60% to 1.70%. is hard and brittle, can be quenched. Hammers, crowbars and other by carbon 0.75% steel; cutting tools such as drills, taps, reamers, made of carbon steel 0.90% to 1%. High hardness (HRC60 65) and good wear resistance can be obtained after heat treatment. 2, under the condition of annealing hardness is moderate, has good machinability. 3, easy access to raw materials, low production costs.Two, blade commonly used materials:1, high speed steel (also known as Feng Steel, Bai Gang): is a kind of tungsten, chromium, vanadium, molybdenum and other high alloy tool steel more elements.2, tungsten carbide hard alloy by high hardness and melting point, titanium carbide and cobalt cemented metal made by powder metallurgy method, the hardness and wear resistance are good, hot hardness is very high, so the cutting speed is higher than high speed steel several times or even several times, can cut material of high speed steel no processing method, but the bending strength and impact toughness of high speed steel much worse than.3, ceramics: alumina powder sintered at high temperature and the ceramic blade, the hardness, wear resistance and heat resistance are higher than the cemented carbide.

- Q: The difference between the turret and the rear turret NC lathe

- The classification processing example scope advantages and disadvantages of different composition of 2.3 ordinary lathe and CNC lathe CNC lathe uses a directory of the two introduction 2.1 CNC lathe 2.2 CNC lathe 2.4 CNC lathe 2.5 CNC lathe CNC lathe CNC lathe 2.6 three 3.1 NC turning process and tooling 3.2 CNC lathe programming 3.3 part four references

- Q: CNC lathe turret and turret turret that good

- First of all, to meet your needs, such as1) you are the object of processing, a fixture may be used to the maximum number of tools, if it is possible to more than four, then the square knife is not appropriate.2) you do not work in the workpiece, drill, tap a class of tools. Or a tail frame, and the tail can be installed on the drill bits and other tools, then you can consider the use of square knife.3) frame structure, different cutter positioning form different tool installation precision, repeated installation accuracy, with the knife and machine are different, if you have this requirement, in the choice of when it is necessary to consider the.

Send your message to us

knife seat,F-KB083 Carbonized bamboo knife seat,your best choice

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords