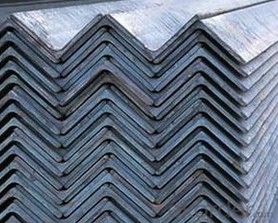

A70*70*7 galvanized angle steel for construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Angle steel is widely used in various building structure and engineering structure.

a.) beam, bridges, ship;

b.) transmission tower, reaction tower;

c.) lifting transportation machinery;

d.) industrial furnace;

e.) container frame, warehouse goods shelves, etc.

Standard | AISI, ASTM, BS, DIN, GB, JIS, etc mild angle steel |

Grade | Q235, Q345, SS400, A36, S235JR,S355JR, ST37-2,ST52, etc |

Equal Angle steel | Type: 2.5#-20# Size: 25-200mm Thickness: 3.0-20mm Weight: 0.597-71.168kg/m |

Unequal Angle steel | Type: 2.5/1.6-20/12.5 Long Side: 25-200mm Short Side: 16-125mm Thickness: 3.0-18mm Weight: 1.687-43.588kg/m |

Length | 5.8-12.0m OR according to client's request |

Element Contect | C<0.22% Si:<0.16% Mn: 0.30—0.65% P<0.060% S<0.060% |

1.Q:how long the goods will be ready for ?

A:some of goods we have stock and normal delivery time is 15-25d ays after received the deposit .

2.Q:How can we get more discount for the order ?

A:first ,T/T payment is much cheaper ,then the more you want the more discount you will be get

3.Q:Can your company provide unequal type angle steel ?

A:Yes , We provide equal angle steel 20*20*3/4 - 200*200*14/16/18/20 and unequal angle steel 25*16*3/4-200*125*12/15/16/18 specification

Protect horn tape is different from the traditional paper tape, using two plating steel to enhance, can protect the corner edge wear does not harm the increasingly into a corner. Protect horn tape more convenient than traditional metal construction. Our corner tape roll is packing, convenient construction and reduce waste. Customers can according to the length of the need to cut, and protect horn tape can be widely used in arch, arc and other edges does not exceed 90 °. Used to form Yang Angle bead surface to withstand shocks, the use of a typical in the Windows and doors mouth department.

The advantages of our products

1) professional mature production line

2) large production capacity.

3)Strict quality testing

4) factory price and best quality

5) fast delivery

6) high efficient after-sales service

7) emergency stockpile

8) we promise all of the queries and emails will get our reply within 24 hours.

- Q: Can steel angles be used in marine applications?

- Indeed, one can utilize steel angles for marine purposes. Given their exceptional strength and durability, steel angles are frequently employed in shipbuilding, offshore platforms, and various marine structures. They serve to offer structural reinforcement and assist in the dispersion of weight and stress within the marine setting. When coated with protective substances or galvanized, steel angles exhibit resistance to corrosion. Nevertheless, it remains crucial to carefully select the appropriate grade of steel angle that is explicitly designed for marine use, guaranteeing optimal performance and longevity in the demanding and corrosive saltwater environments.

- Q: How do you prevent buckling of steel angles under compressive loads?

- To prevent steel angles from buckling under compressive loads, there are several steps that can be taken: 1. Increasing the section modulus: By broadening or thickening the steel angle, its ability to resist bending can be improved, thus enhancing its resistance to compressive loads without buckling. 2. Increasing the moment of inertia: The moment of inertia, which determines a cross-sectional shape's resistance to bending, can be increased by either adding more material or using a different shape with a greater moment of inertia. This makes the steel angle stiffer and less prone to buckling. 3. Providing lateral support: Lateral support can be provided by incorporating bracing or stiffeners into the steel angle. This helps distribute the compressive load and prevents buckling. The bracing or stiffeners should be designed to withstand the applied loads and prevent any local distortions or deformations. 4. Using thicker or higher strength steel: Thicker steel has a higher resistance to bending, while higher strength steel can bear greater stresses before reaching its yield point. By utilizing thicker or higher strength steel, the steel angle can withstand higher compressive loads without buckling. 5. Properly designing and installing connections: The connections between the steel angle and other structural components should be carefully designed and installed. Sufficient connection details should be provided to ensure proper transfer of the compressive load and adequate support for the steel angle. 6. Taking the effective length factor into consideration: The effective length factor is a parameter that considers the buckling behavior of a member. By accurately incorporating the effective length factor into design calculations, the risk of buckling can be minimized. 7. Conducting a comprehensive structural analysis: It is crucial to conduct a structural analysis to determine the expected compressive loads and potential buckling modes. By utilizing appropriate software or calculations, the necessary measures can be implemented to prevent buckling. In conclusion, preventing buckling of steel angles under compressive loads requires a combination of design considerations, material selection, and proper installation techniques. By following these measures, the structural integrity and safety of steel angles can be ensured in various applications.

- Q: Can steel angles be used for framing or supporting suspended ceilings?

- Yes, steel angles can be used for framing or supporting suspended ceilings. Steel angles are commonly used in construction for their strength and durability. They provide structural support and stability, making them suitable for framing and supporting suspended ceilings. Steel angles can be attached to walls or ceilings to create a framework for the suspended ceiling system. They are often used in conjunction with other materials such as hangers, wires, and channels to create a secure and stable structure for the suspended ceiling. Additionally, steel angles can be customized and cut to specific lengths and sizes, making them versatile for various framing and supporting applications.

- Q: Can steel angles be used for framing or supporting mezzanines or elevated platforms?

- Framing or supporting mezzanines or elevated platforms can indeed be achieved with the use of steel angles. In construction projects, steel angles are widely employed due to their structural strength and versatility. They serve as reliable supports or braces in various applications, including the framing of mezzanines or elevated platforms. By providing stability and structural integrity, steel angles prove to be an excellent option for bearing heavy loads and establishing a sturdy framework. Their L-shaped design facilitates easy installation and ensures exceptional resistance against bending and shearing forces. Moreover, steel angles can be effortlessly welded or bolted together, allowing for flexibility in design and construction. All in all, steel angles emerge as a dependable and efficient choice when it comes to framing or supporting mezzanines or elevated platforms.

- Q: How do steel angles contribute to energy-efficient construction?

- Steel angles contribute to energy-efficient construction in several ways. Firstly, steel angles are commonly used as structural components in buildings, such as in the framing of walls, roofs, and floors. Their high strength-to-weight ratio allows for the creation of lighter and more efficient structures. This means that less steel is needed to support the building, reducing the overall weight and material usage, which in turn reduces the energy required for construction and transportation. Secondly, steel angles can be easily prefabricated off-site, allowing for faster construction times and reduced labor costs. This not only saves time and money but also minimizes energy consumption during the construction process. Moreover, steel is a highly durable and long-lasting material, which reduces the need for frequent maintenance and repairs. This durability translates into energy savings over the life cycle of the building, as less energy is required for ongoing maintenance and replacements. Additionally, steel angles can be recycled at the end of their life cycle, reducing the demand for virgin materials and minimizing the environmental impact of construction. The recycling process requires less energy compared to the production of new steel, resulting in energy savings and reduced greenhouse gas emissions. Lastly, steel angles can be integrated into energy-efficient building systems, such as insulation, HVAC ductwork, and renewable energy installations. The versatility of steel allows for the creation of systems that optimize energy performance, such as efficient heating and cooling systems or solar panel installations. In conclusion, steel angles contribute to energy-efficient construction by providing strength and stability while reducing material usage, enabling faster construction times, minimizing maintenance needs, facilitating recycling, and integrating with energy-efficient building systems.

- Q: What is the minimum thickness for a steel angle?

- The specific application and requirements determine the minimum thickness for a steel angle. Typically, steel angles come in various thicknesses, beginning at approximately 1/8 inch (3.175 mm) and extending to multiple inches thick. Nevertheless, it is crucial to consider factors like the load it will support, the structural design, and any applicable building codes or industry standards when determining the minimum thickness for a steel angle. Seeking advice from a structural engineer or referring to relevant guidelines can offer more precise information on the minimum thickness necessary for a steel angle in a particular scenario.

- Q: What are the maintenance requirements for steel angles?

- The maintenance requirements for steel angles typically involve regular cleaning and inspection for signs of corrosion or damage. It is important to remove any dirt or debris that may accumulate on the surface of the steel angles, as they can potentially lead to corrosion. Additionally, it is advisable to apply a protective coating or paint to prevent rusting. Routine inspections should be conducted to identify any signs of wear or structural issues that may require repairs or replacements.

- Q: What is the typical size range for steel angles?

- The typical size range for steel angles varies, but commonly, they range from 1/2 inch to 8 inches in width and thickness.

- Q: Can steel angles be used as reinforcing bars in concrete structures?

- Yes, steel angles can be used as reinforcing bars in concrete structures. However, it is important to ensure that the steel angles meet the required specifications for reinforcement, such as having the necessary strength and ductility. Additionally, proper design and detailing considerations must be taken into account to ensure effective anchorage and bonding between the steel angles and the surrounding concrete.

- Q: What do you mean by "corner steel plate pull knot"?

- The angle iron can be made up of different force components according to the different structure, and can also be used as the connecting piece between the components. Widely used in a variety of architectural and engineering structures, such as beams, bridges, towers, hoisting and conveying machinery, ships, industrial furnace, reaction tower, container frame and warehouse.

Send your message to us

A70*70*7 galvanized angle steel for construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords