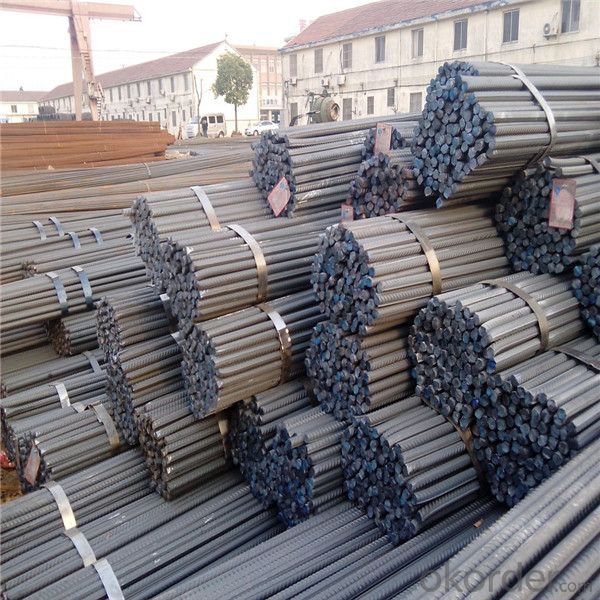

Iron rods of 6-25MM HRB400 HRB500 for building

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 18000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Deformed Steel bar is a common steel reinforcing bar, used in reinforced concrete and reinforced masonry structures.

It is formed from mild steel, and is given ribs for better frictional adhesion to the concrete. The Deformed Steel bar is an

iron rod , a weldable plain reinforcing steel bar, and can be used as well for steel meshes.

To prevent workers from accidentally impaling themselves, the protruding ends of steel rebar are often bent over or covered

with special plastic "mushroom" caps.

Our Advantage: High quality steel products from 1 class mills in China

Reasonable price

Professionalism of the products

On-time delivery

Complete documents and certificates

Sincere service to meet our clients' requirements

Product Description :

Chemical composition (%): | Steel | C | Si | Mn | P | S | Ceq | ||||

HRB335 |

0.25 |

0.80 |

1.60 |

0.045 |

0.045 | 0.52 | |||||

HRB400 | 0.54 | ||||||||||

HRB500 | 0.55 | ||||||||||

Mechanical properties | Steel | Rel/ MPa | Rm/ MPa | A/ % | Agt/ % | ||||||

≥ | |||||||||||

HRB335 | 335 | 455 | 17 |

7.5 | |||||||

HRB400 | 400 | 540 | 16 | ||||||||

HRB500 | 500 | 630 | 15 | ||||||||

Package: | Standard export packing or as customer's request | ||||||||||

Application: | Construction, building, bridge, road. ect | ||||||||||

Payment terms | 1).100% irrevocable L/C at sight. | ||||||||||

Delivery time | 15-30 days after receipt of L/C or deposit by T/T | ||||||||||

Packing:

In bundles, each bundle weight 3.5 tons. Load by container or by bulk verssel.

Our service

(1) We cooperate with famous factories with advanced equipment and well trained workers.

(2) We can provide factory price with trading company service.

(3) We continuously work on the improvement of our processes, guaranteeing consistently high standards

of quality to keep none compensation.

(4) We guarantee 24 hours response and 48 hours solution providing service.

(5) We accept small order quantity before formal cooperation.

(6) We deliver the agreed quality at the agreed time, reacting to changes in customer wishes in a flexible way.

(7) Due to our volume and selling power, we have excellent freight rates with shipping lines.

(8) We strive to always be fair and honest in our dealings with customers.

(9) We strive to work together with customers to achieve much more than we can achieve alone.

(10) Through our passion and commitment we aim to be a market leader in all our key markets. To maintain

our position as market leader we must continue to add value in all that we do.

FAQ:

1.Q: What's your MOQ(minimum order quantity)?

A: One full container, mixed acceptable .

2. Q: What's your packing methods?

A: Packed in bundle or bulk ..

3. Q: How can I buy CNBM products in my country?

A:Please send us an inquiry or email ,we will reply to you if there is distributor in your country

4. Q: Can we visit your factory?

A: Warmly welcome. Once we have your schedule, we will arrange the professional sales team to follow up your case.

5. Q: How long does it take to get the product if i place an order?

A:With the process of your requirements,we will pack and deliver in 3-7 days. If it is by sea shipment,it will take 15-45 days depending on different locations

- Q: What are the guidelines for the proper lap splicing of steel rebars?

- The guidelines for the proper lap splicing of steel rebars include ensuring that the rebars are clean and free from rust, dirt, or any other contaminants. The spliced rebars should have appropriate overlapping lengths as specified by the design engineer. The lap splice should be made using mechanical splicing methods or approved splice connectors to ensure proper load transfer. The spliced rebars should be securely positioned and aligned to maintain the required concrete cover. It is essential to follow the specific codes and standards set by the construction industry for lap splicing to ensure the structural integrity and safety of the reinforced concrete structure.

- Q: What are the factors to consider while calculating the required number of steel rebars in a project?

- Some factors to consider while calculating the required number of steel rebars in a project include the structural design and requirements, the load-bearing capacity needed, the dimensions and layout of the structure, the type and grade of steel rebar being used, and any applicable building codes and regulations. Additionally, factors such as the spacing between rebars, the concrete cover thickness, and any potential corrosion protection measures may also need to be considered.

- Q: How are steel rebars stored and handled on construction sites?

- Steel rebars are typically stored in designated areas on construction sites to ensure easy access and organization. They are often stacked horizontally and secured with supports to prevent them from rolling or falling. When handling rebars, workers wear appropriate protective gear and use equipment such as cranes or forklifts to lift and move them safely. Additionally, rebars are carefully inspected for any defects or damages before being used in construction projects.

- Q: Can steel rebars be used in stadium construction?

- Steel rebars are indeed applicable for stadium construction. These reinforcing steel bars are frequently utilized in concrete construction to confer robustness and stability. In the realm of stadium construction, steel rebars are extensively incorporated into reinforced concrete structures like columns, beams, slabs, and foundations. They are strategically positioned within the concrete to augment its capacity to bear loads and avert cracking or failure amidst substantial burdens and vibrations. By employing steel rebars, the stadium's structural integrity and longevity are ensured, granting it the ability to endure the tremendous pressures and forces exerted during sporting events and gatherings of a considerable audience.

- Q: Are there any specific guidelines for storing and handling steel rebars?

- Specific guidelines exist for the storage and handling of steel rebars. Take note of the following essential points: 1. Storage: To prevent corrosion, it is necessary to store steel rebars in an area that is clean, dry, and well-ventilated. Place them on timber or other suitable materials to keep them elevated and away from moisture. 2. Handling: Exercise caution when handling steel rebars to avoid any damage or bending. It is advised to use appropriate equipment like cranes, forklifts, or sturdy hooks for lifting and moving rebars. Dragging or dropping them should be avoided as it may cause deformations and compromise their structural integrity. 3. Bundling: Properly bundle and secure rebars together using steel wires or straps to prevent rolling or shifting during storage or transportation. This ensures stability and reduces the risk of accidents. 4. Separation: Keep different sizes and types of rebars separate and clearly labeled to prevent confusion during construction. This facilitates easy identification and utilization of the required rebar according to the structural plans. 5. Protection: Guard rebars against exposure to moisture, rain, snow, and other weather elements. When storing rebars outdoors, utilize waterproof covers or tarps to shield them and prevent the formation of rust. 6. Inspection: Regular inspections should be conducted to identify signs of corrosion, damage, or bending. Any defective or compromised rebars must be promptly removed and replaced to maintain the structural integrity of the construction project. 7. Transportation: During transportation, ensure that rebars are securely fastened and loaded onto appropriate vehicles to prevent movement or falling off. Employ sufficient padding and tie-downs to protect rebars from damage and ensure safe transportation. Adhering to these guidelines is crucial in upholding the quality, durability, and safety of steel rebars throughout their storage and handling process.

- Q: What is the role of steel rebars in load-bearing walls?

- The role of steel rebars in load-bearing walls is to provide reinforcement and strength to the structure. These rebars are embedded within the concrete to enhance its tensile strength and prevent cracking or collapsing under heavy loads. By distributing the load evenly throughout the wall, steel rebars help ensure the wall's stability and durability, making it capable of supporting the structure's weight and resisting external forces.

- Q: How are steel rebars coated with epoxy?

- Steel rebars are coated with epoxy through a process called fusion bonding. In this process, the rebars are first cleaned and preheated, and then a layer of epoxy powder is applied to their surface. The rebars are then heated to a high temperature, causing the epoxy powder to melt and fuse with the steel, creating a durable and protective coating.

- Q: How are steel rebars manufactured and processed?

- Steel rebars are manufactured and processed through a series of steps. Firstly, the raw materials like steel billets or scrap metal are melted in a furnace to create molten steel. This molten steel is then poured into molds of desired shapes and sizes to form billets. These billets are further processed through a rolling mill, where they are heated and passed through a series of rollers to shape them into long, thin bars. The bars are then cooled, straightened, and cut into desired lengths. To enhance their strength, rebars are often subjected to heat treatment or alloying processes. Finally, they undergo surface treatment, such as corrosion-resistant coatings, to protect against rusting. The finished steel rebars are then ready for use in construction and reinforcing concrete structures.

- Q: Can steel rebars be used in underground structures?

- Yes, steel rebars can be used in underground structures. Steel rebars are commonly used in construction, including underground structures such as tunnels, basements, and foundations. The high strength and durability of steel rebars make them suitable for reinforcing concrete structures in underground environments, providing enhanced structural integrity and ensuring long-term stability and safety.

- Q: What is the process of removing steel rebars from concrete structures?

- The process of removing steel rebars from concrete structures typically involves several steps. First, the concrete surface around the rebar is often chipped away using pneumatic tools or jackhammers to expose the steel. Then, an oxyacetylene torch or a cutting disc is used to cut the rebar into smaller, more manageable pieces. If the rebar is embedded deep within the concrete, a core drilling machine may be used to create a hole around the rebar, allowing for easier removal. Finally, once the rebar is cut or loosened, it can be extracted using heavy machinery or manual labor, depending on the size and weight of the rebar.

Send your message to us

Iron rods of 6-25MM HRB400 HRB500 for building

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 18000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords