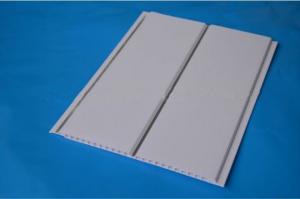

interior board

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 120000pcs pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

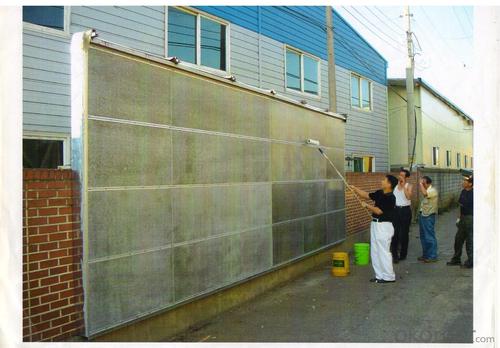

1,LUTAI Fiber cement board is a stable performance and light weight building &decoration board used cement as major and natural reinforced, with the process of pulping,emulsion,forming,pressurization,autoclaving,

drying and surface treatment.

Thickness : 4.5mm-30mm

Size :1200*2400mm, 1220*2440mm, any size that u need .

Surface : 40#-120# sanding surface , polished surface , tapered edge .

2,Product characteristics :

Density : 1.2-1.5G/CM3

Fire-proof Rate : A-Class incombustible (GB8624-1997)

Incombustibility(min): 240 minutes (GB/T9978-1999)

Water content : ≤30% Swelling ratio: ≤0.4%

Anti-bending Strength: ≥16MPA Frost resistance : Don’t appear cracking and delamination after 25 cycles of freezing and thawing . (GB/T7019-1997)

Radioactivity: standard of GB6566-2001 (A-class Decoration Materials)3,Recommed application:

Partition board , exterior wall cladding , panel, suspended ceilings ,lightweight grouting panel, interior dry wall decoration board ,interior wall after painting and coating .

- Q: Is the cement board a cement pressure plate? What's the difference?

- Cement board and cement pressure plate is a product of the two names, in fact, no difference. Plate of cementitious materials are cement

- Q: Is it a decoration material? What's the difference?

- Wood and Miyan cement board is a decoration material, like a large piece of gypsum board, the size is 1220X2440 (MM), wood grain cement board is more delicate, more beautiful rock.

- Q: I am laying a new tile floor over plywood subfloor. I have Durock cement backerboard. The area I'm covering is only 4'3 x 6'8. I don't really want to put the money out for power saws ($60+) so I am planning to use a hand saw. What kind is most appropriate? Can I use a small utility knife for the smaller details?

- score with a razor knife and then break. you can use a hand saw also, the board should actually have printed on it to cut this side . good luck

- Q: or add visquine on top of the plywood and then put on the backer board

- That is the proper way to do it. You need the thin set to act as a filler so there are no voids at all between the ply and the cement board. 1/4x1/4 notched trowel is the required trowel. This is according to tile installation ( both ATC and TCA tile guide line codes) and the cement board manufactures way to do it. Any questions you can e mail me through my avatar and check my qualifications there. GL

- Q: How to choose the external wall of fiber composite insulation board fire isolation zone

- Different regions can choose different foam thickness of the insulation decorative plate. The bottom of the different needs of customers moisture, insulation, fire-retardant aluminum foil, high-quality steel plate protective layer.

- Q: What is the use of fiber cement board

- Fiber cement board, also known as fiber reinforced cement board, is based on fiber and cement as the main raw material for the production of cement cement plate. ?????? Fiber cement board is mainly used in construction ceiling, partition wall and other parts, can also be used for steel structure and steel floor and other parts of the floor. Often used in various types of domestic power plants, chemical companies and other electricity-intensive places of the cable project fire retardant. But also large shopping malls, hotels, hotels, documents Hall, closed clothing market, light industry market, theaters and other public places, interior decoration fire retardant project the best fire retardant materials.

- Q: I've already got the cement board down, taking it back up would mean messing with the toilet flange, which means plumbing, and that sucks. Plywood was in pretty good condition. Thanks in advance!

- Just use a bunch of screws to hold the cement board in place. If you do this it will be just fine.

- Q: How to fix the cracks in the ceiling

- In the cast-in-place concrete slab cracks at the cracks will be 15cm wide surface layer to wear, and clean up, after the use of carbon fiber special glue will be 10cm wide carbon fiber ride stitch paste, and other plastic dry putty scraping;

- Q: I've done the hard way - bunches of expensive special screws. I found that to be expensive and time consuming (and therefore back breaking). It seems like it takes just as long to do the backer board as it does to do all the remaining steps with the tile. Can I use nails? If so, what kind? Thinset and nails? The subfloor is plywood with old vinyl tiles, I have no intention of remove the old vinyl tiles first. Please reply if you have personal experience with an alternative. Thanks!

- If you want it to last you should thin set AND screw the cement board down. Cement board is not just used in wet areas. It is a dimensionally stable product and properly installed it will keep your tile and grout from cracking and/or coming loose. If you try to scimp on the prep then you will be wasting your time and money. Some installers do nail it down but bare in mind that this will void any warranty. Don't forget to tape the joints too. If the vinyl tiles are down tight and height room to room is not an issue then leave it in place and go over top.

- Q: Gypsum board and cement board decoration room difference

- Cement pressure plate is a glass fiber and cement as raw material, by the pulp, forming, cutting, pressure, steamed from a new type of building plate. With light, high strength, waterproof, anti-corrosion, fire, good processing and so on. In the interior decoration, the general when the wall needs to tile, with cement board hanging, can withstand greater weight, to avoid wall off.

Send your message to us

interior board

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 120000pcs pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords