Insulating Fire Brick - High Temperature Insulation Fireclay Refractory Brick

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t

- Supply Capability:

- 2000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Insulating Brick

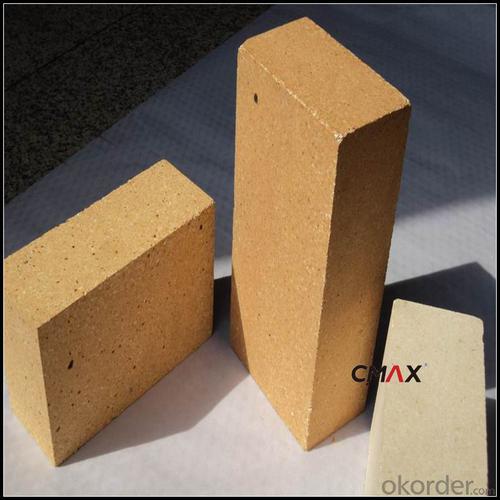

CMAX insulating firebricks are classified under temperature between 1300℃ to 1700℃, manufactured from high purity alumina clay.

Insulating fire brick with light weight, has high mini-porosity arranged in average,

keep furnace wall low radiation and depress the charges of fuels.

Light weight for IFB means the lowest thermal storage, it’s quicker to heat and cool, and permit rapid cycle work.They are used for 900℃ -1650℃ customer can select the most economical products according to service temperature.

Insulating Brick Features

1. Good price

2. Raw material from China, Australia and Germany

3. Certificate of Quality for each parcel

4. Many sizes in stock ; Making tiles accroding to your drawings

5. Resistance: Excellent

6. Quick delivery& Professional service

Insulating Brick Application

High-temperature kiln and furnace hot face’s lining

Insulating backup

Infra red element support

Glass tank side and end wall & port neck insulation

Nuclear insulation application

Industrial combustion chamber construction

Insulating Brick Data Sheet

Classification Temperature (℉/℃) | 3000/1650 |

Bulk Density (g/cm3 ) | ≤1.0 |

Thermal Conductivity | |

800℃, W/m.K | ≤0.39 |

1000℃, W/m.K | ≤0.43 |

1200℃, W/m.K | ≤0.48 |

Reheating Linear Change (%) | 1550℃×12h |

≤0.9 | |

Chemical Composition (%) | |

Al2O3 | ≥75 |

Fe2O3 | ≤0.5 |

Packaging & Shipping

Packaging Details:Be packed in fumigated wooden pallets

Delivery Detail: 30 days after order

Our Services

Optimum solution and product supply of refractories for high temperature industries, such as iron steel, non-ferrous, petrochemical and building materials.

Engineering design, contract and consult for refractories, and civil architecture design.

Research, development, manufacture and sale of superhard materials.

R&D, manufacture and sale of special packing materials for export.

Inspection, supervision and arbitration of refractories.

Consultation and services in refractories information.

Training and cultivation of high-level talents in refractories profession

Sales Network

Company Information

CNBM (China National Building Material) Group is the largest comprehensive building materials group in China that in integrate scientific research, manufacturing and logistics into one entity. The largest building materials and equipment specialists in China. Upon State Council approval, today CNBM owned more than 300 subordinate manufacturing factories and servicing companies. There are 6 fully owned public listed companies and 11 partially owned with substantial shares public listed companies. In many of these fields, CNBM is playing the leading role in the building industry in the country.

FAQ

1. Which products do you have?

We have all kinds of refractory brick, castable, mortar, cement, ceramic fiber products, etc.

Or you could browse our products to choose what you need.

2. Can you give me a brief introduction of the application of your products?

We are mainly specializing in the refractory materials in iron and steel, cement, glass, ceramics, petrochemical, electric power Industry, etc.

3. If I need your offer, what information do you need?

In order to choose suitable products, it will be appreciated to provide us the information, such us specification, technical data, order quantity, products application etc. If any question, please contact us freely.

- Q: Can insulating fire bricks be used in the construction of flue gas ducts?

- Insulating fire bricks have the capability to be utilized in the construction of flue gas ducts. These bricks are specifically engineered to endure high temperatures and offer exceptional thermal insulation. This makes them an apt choice for lining flue gas ducts as they aid in reducing heat loss and enhancing energy efficiency. Moreover, insulating fire bricks exhibit resistance to chemical corrosion and can withstand the harmful impacts of flue gases. Nevertheless, it is crucial to guarantee that the insulating fire bricks employed are specifically designed for flue gas duct applications and fulfill the required safety and regulatory standards. Seeking advice from a professional engineer or a specialist in this field is advised to ensure the accurate selection and installation of insulating fire bricks in flue gas ducts.

- Q: Are insulating fire bricks suitable for use in kilns?

- Yes, insulating fire bricks are suitable for use in kilns. Insulating fire bricks are specifically designed to withstand high temperatures and provide excellent insulation properties. They are made from lightweight materials that have low thermal conductivity, allowing them to retain heat efficiently and reduce heat loss. This makes them ideal for lining kilns as they help to maintain consistent and controlled temperatures, improving energy efficiency and reducing fuel consumption. Additionally, insulating fire bricks have good resistance to thermal shock, meaning they can withstand rapid and extreme temperature changes without cracking or breaking. Overall, insulating fire bricks are a reliable and effective choice for kiln linings, ensuring optimal performance and prolonging the lifespan of the kiln.

- Q: Can insulating fire bricks be used for insulation in ovens and kilns?

- Yes, insulating fire bricks can be used for insulation in ovens and kilns. Insulating fire bricks are specifically designed to withstand high temperatures and provide excellent thermal insulation. They are made from lightweight materials like clay and other refractory materials that have low thermal conductivity. This means that they can effectively retain heat and prevent it from escaping, making them ideal for use in ovens and kilns where heat retention is crucial. Additionally, insulating fire bricks are resistant to thermal shock, meaning they can withstand rapid changes in temperature without cracking or breaking. Overall, insulating fire bricks are a reliable choice for insulating ovens and kilns, ensuring efficient heat distribution and energy conservation.

- Q: Do insulating fire bricks have a high insulation efficiency?

- Yes, insulating fire bricks have a high insulation efficiency. These types of bricks are specifically designed to provide excellent thermal insulation properties. They are made from lightweight materials with low thermal conductivity, such as various types of refractory clay or alumina. This composition allows them to effectively minimize heat transfer through conduction, making them highly efficient at retaining heat within a structure or appliance. Insulating fire bricks also have a high porosity, which further enhances their insulation capabilities. The presence of numerous small air pockets within the bricks reduces heat transfer by convection, as the air acts as an insulating barrier. This unique structure helps to maintain a consistent and stable temperature, whether it is in a furnace, kiln, or any other high-temperature environment. Furthermore, insulating fire bricks have high resistance to thermal shock, meaning they can withstand rapid changes in temperature without cracking or deteriorating. This property is crucial in applications where temperature fluctuations are common, as it ensures the longevity and effectiveness of the insulation. Overall, insulating fire bricks are known for their high insulation efficiency. They provide excellent thermal insulation, prevent heat loss, and contribute to energy savings. Whether used in industrial settings or residential constructions, these bricks offer reliable insulation performance and contribute to the overall energy efficiency of the system they are employed in.

- Q: Can insulating fire bricks be used in textile industry kilns?

- Insulating fire bricks are indeed applicable in the textile industry kilns. These bricks are specifically designed to endure extreme temperatures while providing exceptional insulation, rendering them appropriate for kiln usage. Within the textile industry, kilns are utilized for multiple procedures including fabric dyeing, drying, and curing. Implementing insulating fire bricks in these kilns guarantees the maintenance of a consistent and regulated temperature, resulting in efficient and uniform dispersion of heat. Furthermore, these fire bricks aid in minimizing heat loss, thereby leading to energy conservation and enhanced operational effectiveness. Hence, due to their thermal insulation properties and ability to endure high temperatures, insulating fire bricks are an ideal choice for textile industry kilns.

- Q: Do insulating fire bricks require any special anchors or supports for installation?

- Special anchors or supports are necessary for the installation of insulating fire bricks in certain applications. These bricks are lightweight and have low thermal conductivity, making them suitable for high-temperature environments like furnaces, kilns, and fireplaces. However, their lightweight nature can cause them to move or shift under certain conditions. To ensure the stability and integrity of the insulating fire bricks, it is important to use special anchors or supports during installation. These anchors or supports are typically made of metal, such as stainless steel, and are designed to securely hold the bricks in place. They prevent the bricks from shifting or falling out, especially when exposed to vibrations, thermal expansion/contraction, or other external forces. The specific type and design of the anchors or supports depend on the application and installation requirements. Common types include V anchors, U anchors, and L anchors, which can be embedded into the surrounding refractory material or attached to a structural frame. The anchors or supports should be spaced and installed correctly according to the manufacturer's guidelines to ensure sufficient support and stability of the insulating fire bricks. In conclusion, although insulating fire bricks offer excellent thermal insulation properties, they require special anchors or supports for installation to prevent movement or displacement. These anchors or supports are crucial for maintaining the structural integrity and longevity of the insulating fire brick system.

- Q: Is it possible to recycle broken insulating fire bricks?

- Yes, it is possible to recycle broken insulating fire bricks. These bricks can be crushed and used as aggregate in the production of new bricks or other construction materials. Additionally, they can be ground into a fine powder and used as a raw material in the manufacturing of refractory products. Recycling broken insulating fire bricks helps reduce waste and conserve resources.

- Q: Is it possible to repair damaged insulating fire bricks?

- Repairing damaged insulating fire bricks is indeed possible, and the method required will depend on the extent and type of damage. For minor cracks or chips, one can utilize a refractory mortar that is specifically designed to endure high temperatures and create a strong bond. This mortar can effectively fill in the gaps and restore the brick's integrity. However, if a larger section of the brick is damaged or completely missing, it may be necessary to replace the entire brick. In such a scenario, the damaged brick must be cautiously removed, and a new one can be installed with the appropriate refractory mortar. It is crucial to ensure that the repaired or replaced brick adheres to the original specifications and quality to guarantee proper insulation and structural integrity. It is highly recommended to seek advice from a professional or carefully follow the manufacturer's guidelines for the specific repair process.

- Q: Are insulating fire bricks easy to cut and shape?

- Indeed, cutting and shaping insulating fire bricks proves to be relatively simple. These bricks consist of lightweight refractory materials like ceramic fibers, enabling them to be more manageable when compared to traditional fire bricks. Common tools such as saws, knives, or chisels can be employed to cut and shape these insulating fire bricks. Due to their lightweight composition, they can be easily maneuvered and positioned, facilitating more accurate cuts and shapes. Moreover, if necessary, openings or specific designs can be effortlessly drilled or carved into these bricks. Overall, the convenience of cutting and shaping insulating fire bricks makes them an ideal choice for various applications in construction, insulation, and fireproofing.

- Q: Can insulating fire bricks be recycled?

- Yes, insulating fire bricks can be recycled. These bricks are often made from materials such as clay, shale, or kaolin, which can be crushed and reused to make new bricks. Additionally, some manufacturers offer recycling programs where old or damaged fire bricks can be returned and repurposed. Recycling insulating fire bricks is an environmentally-friendly solution that helps reduce waste and conserve resources.

Send your message to us

Insulating Fire Brick - High Temperature Insulation Fireclay Refractory Brick

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t

- Supply Capability:

- 2000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords