GJM 23 Light Dense Mullite Insulating Fire Brick

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Thermal Insulation Fire Clay Brick

Refractory brick is a refractory material used in lining furnaces, kilns, fireboxes, and fireplaces.

We provide high quality Refractory Fire Bricks that are used on wide range in the various industries like Cement, Glass and Steel. Refractory Fire Bricks are provided as per the quantity and specifications required by the customers. We provide an extensive range of Refractory Fire Bricks at reasonable prices that depend upon the quantity ordered.

Application

Insulating Fire Brick are used for the lining of converter, alternating current arc furnace, direct Current arc furnace and the ladle slag line, etc.

Company Advantage

(1)Long Insulating Fire Brick manufacture history: 25 years manufacturer

(2)Advanced equipment and good service

(3)Diversification of production standards: ISO ANSI FEPA JIS ASTM

(4)Flexible payment: T/T L/C D/P D/A

(5)Professional marketing team and after-sale service

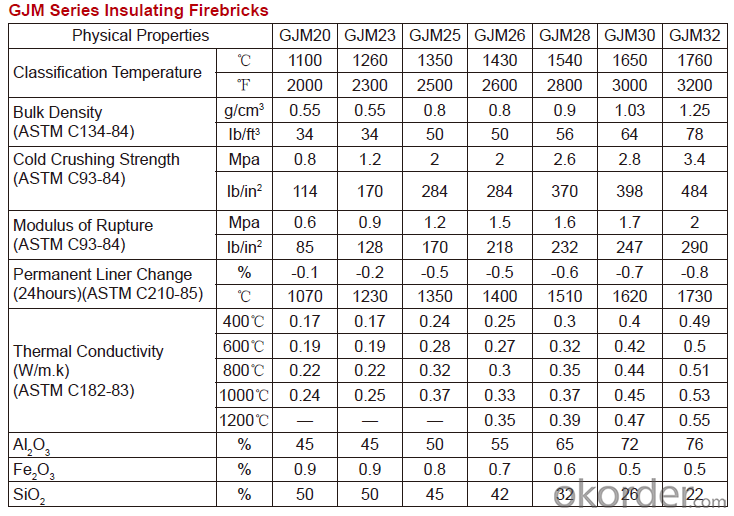

Insulating Fire Brick main feature:

Equipment

1 unit of Ceramic Abrasive (SG Abrasive) pilot production line

2 units of Compact grain Abrasive pilot production lines

1 unit of high-end coated abrasives (abrasive cloth) production line

3 large flexible crushing and sieving lines for grit production lines

6 units of 5000KVA-10000KVA dumping type electric arc furnaces for Brown Fused Alumina fusion

FAQs

Q1 What’s the transport method?

A1 FCL delivery goods with wooden pallet or wooden case by sea; If LCL delivery, must with wooden case; Sometimes need open top, flat rack or bulk cargo.

Q2 What’s the required payment term?

A2 Generally 30% TT as the prepayment, 70% TT before delivery. If need, 100% Irrevocable Letter of Credit or negotiation.

Q3 Which country are our products exported to?

A3 Apart from entire Chinese market, the US, Russia, Japan, Korea, Australia and some Southeast Asian Nations.

- Q: Can insulating fire bricks be used in cryogenic applications?

- Yes, insulating fire bricks can be used in cryogenic applications. These bricks have low thermal conductivity and are capable of withstanding extremely low temperatures, making them suitable for insulation in cryogenic environments.

- Q: How long do insulating fire bricks last?

- Insulating fire bricks have a relatively long lifespan, typically lasting for several decades under normal usage conditions.

- Q: Can insulating fire bricks be used in rocket stoves?

- Insulating fire bricks are indeed suitable for use in rocket stoves. Their high insulation properties make them a popular choice. These bricks are composed of lightweight refractory materials, such as silica, which have low thermal conductivity. As a result, they can endure high temperatures while minimizing heat loss. This makes them an ideal option for rocket stoves. Rocket stoves are designed to burn biomass fuel, like wood or charcoal, efficiently. They do this by creating a combustion chamber with a vertical chimney. Insulating fire bricks can be used to construct the combustion chamber and line the chimney. This ensures that the heat generated by the fire is effectively contained and directed towards the cooking surface. Using insulating fire bricks allows rocket stoves to achieve higher temperatures and maintain them for longer periods. This leads to more efficient and effective cooking, as well as reduced fuel consumption. Furthermore, the insulating properties of these bricks also help protect the surrounding environment from excessive heat, reducing the risk of accidental burns or fires. In conclusion, insulating fire bricks are a suitable choice for rocket stoves due to their ability to withstand high temperatures, minimize heat loss, and improve cooking efficiency.

- Q: Are insulating fire bricks resistant to metal penetration?

- Insulating fire bricks possess a general resistance to the penetration of metal. These bricks are composed of refractory materials with high melting points and are engineered to endure elevated temperatures. Their application is often found in environments subject to extreme heat, such as furnaces and kilns. The thermal conductivity of insulating fire bricks is low, denoting their effectiveness in impeding heat transfer. This characteristic aids in maintaining a cool outer surface for the bricks, even when the interior is subjected to intense heat. Consequently, such bricks exhibit the ability to withstand the infiltration of molten metal. Nonetheless, it is worth noting that the resistance of insulating fire bricks to metal penetration varies according to the individual composition and quality of the bricks. Inferior-grade bricks may not offer the same level of resistance as their higher-quality counterparts. Furthermore, the duration and intensity of exposure to heat can also influence the bricks' resistance. In conclusion, while insulating fire bricks generally exhibit resistance to metal penetration, it is vital to consider the specific attributes and quality of the bricks employed, as well as the conditions under which they are exposed to heat.

- Q: Are insulating fire bricks porous?

- Yes, insulating fire bricks are porous. Porosity is a characteristic of insulating fire bricks that allows them to have low thermal conductivity. These bricks are made from ceramic materials and contain a high percentage of tiny air pockets or voids, which trap and slow down the transfer of heat. This porosity also makes the bricks lightweight and resistant to thermal shock. The ability of the insulating fire bricks to retain heat and provide effective insulation is directly linked to their porous structure.

- Q: Are insulating fire bricks resistant to flame impingement?

- Yes, insulating fire bricks are resistant to flame impingement.

- Q: Are insulating fire bricks resistant to nitric acid?

- Insulating fire bricks usually lack resistance against nitric acid, a highly corrosive substance that can dissolve various materials, including specific types of fire bricks. Although insulating fire bricks are intended for enduring high temperatures and providing thermal insulation, they may not possess the required chemical resilience to withstand the corroding impact of nitric acid. When anticipating exposure to nitric acid, it is recommended to employ materials specifically engineered for acid resistance in such situations.

- Q: Do insulating fire bricks expand and contract with temperature changes?

- Insulating fire bricks do indeed undergo expansion and contraction in response to temperature variations. Similar to all other materials, exposure to heat causes these bricks to expand, whereas cooling leads to their contraction. This expansion and contraction phenomenon arises from the material's thermal expansion coefficient, which dictates the degree of expansion or contraction in relation to temperature changes. It is crucial to acknowledge this characteristic when utilizing insulating fire bricks in situations that involve anticipated temperature fluctuations. Neglecting to account for the expansion and contraction may result in structural harm or the formation of cracks.

- Q: Can insulating fire bricks be used in wastewater treatment plants?

- Indeed, insulating fire bricks have the capability to be utilized within wastewater treatment plants. Specifically engineered to endure extreme temperatures, insulating fire bricks are fitting for a variety of industrial applications, including wastewater treatment plants. They are commonly implemented in constructing kilns, furnaces, and other equipment that operates at high temperatures. Within wastewater treatment plants, insulating fire bricks can be incorporated into the assembly of incinerators, thermal oxidizers, and other systems that necessitate high-temperature insulation. Their exceptional properties, such as remarkable thermal resistance, minimal thermal conductivity, and exceptional insulation abilities, make them an ideal choice for maintaining the desired temperatures in these systems while simultaneously diminishing heat loss. Moreover, insulating fire bricks demonstrate resistance to chemical attacks, a vital characteristic within wastewater treatment plants that handle a plethora of chemicals and corrosive substances. In summary, the utilization of insulating fire bricks in wastewater treatment plants can lead to enhanced energy efficiency, reduced maintenance expenses, and the assurance of longevity for high-temperature equipment.

- Q: There are several construction techniques for exterior wall insulation

- Exterior wall sandwich insulation technologyThe exterior wall sandwich insulation is to place the heat preservation material between the inner and outer wall sheets of the outer wall, and the inner and outer walls can be made of concrete hollow blocks.Advantage:1) to the inner wall piece and the heat preservation material forms the effective protection, to the heat preservation material selection material request is not high (source: Chinese heat preservation net), polystyrene, glass cotton and urea aldehyde field casting material and so on may use;2) the construction season and construction conditions are not very high, and it does not affect the winter construction. In Heilongjiang, Inner Mongolia, northern Gansu and other cold areas have been given some applications.Shortcoming:1) in non cold areas, this kind of wall is thicker than traditional wall;2) the inner and the outer wall pieces need to be connected by connecting pieces, and the structure is more complicated than the traditional wall;3) periphery structure of "bridge" more. In the earthquake zone, building circle beam and constructional column settings, "bridge" more efficiency of thermal insulation materials is still not fully play.4) outside the walls by the outdoor climate, the temperature difference between day and night and the large temperature difference between summer and winter, easy to cause the wall cracking and leakage of rainwater.

Send your message to us

GJM 23 Light Dense Mullite Insulating Fire Brick

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords