Insulating Fire Brick - Lightweight for Steel Pipe

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

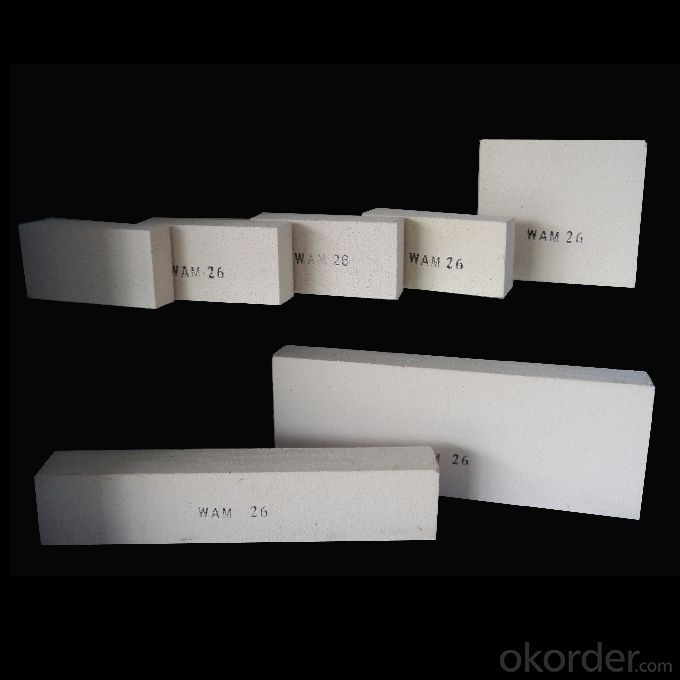

Insulating Fire Brick with Light Weight are high performance insulation products manufactured with unique shot removing and vacuum forming process, provide excellent high temperature stability, extra low thermal conductivity and compressive strength.

Advantages of Insulating Fire Brick:

Low thermal conductivity.

High strength and resistance to corrosion.

Low heat capacity.

Low shrinkage after heavy firing.

High insulation

High refractoriness.

Low density.

Applications:

Insulating Fire Brick is highly applied in below:

Steel furnaces

Iron making furnaces

Glass kiln

Ceramic tunnel kiln

Cement kiln

FAQ:

Payment term:T/T 30 deposit after order confirmed,the balance after goods ready before shipping,or L/C, or Western Uninon for small amount.

Lead time:Normally in 5-10 days after deposit received

Sample apolicy:Sample are always available for each modle

Shipping port: Tianjing

Technical Data Sheet:

Item | Insulating Fire Brick with Light Weight | |||

0.6 | 0.8 | 1.0 | 1.3 | |

Al2O3 (%) | 40 | 40 | 40 | 40 |

Fe2O3 (%) | 1.5 | 1.5 | 1.2 | 2 |

SiO2 | 55 | 55 | 55 | 55 |

Bulk Density (g/cm3) | 0.6 | 0.8 | 1.0 | 1.2 |

Apparent Porosity % | 70 | 60 | 55 | 50 |

Cold Crushing Strength (Mpa) ≥ | 2.0 | 2.5 | 3.0 | 4.0 |

Reheating Linear Change (%)°C X 12H ≤ | 1300℃ -0.5 | 1350℃ -0.5 | 1350℃ -0.9 | 1350℃ -0.9 |

Thermal Conductivity((W/m.k)(1000°C) | 0.33 | 0.60 | 0.45 | 0.80 |

Max Service Temperature (°C) | 1200 | 1280 | 100 | 1350 |

- Q: Are insulating fire bricks suitable for insulation in heat treatment furnaces?

- Insulation in heat treatment furnaces can be effectively achieved by using insulating fire bricks. These bricks have been specifically engineered to endure high temperatures while offering exceptional thermal insulation. Their low thermal conductivity aids in reducing heat loss and ensuring a consistent temperature within the furnace. Furthermore, insulating fire bricks are lightweight, facilitating easier handling and installation. Moreover, they exhibit considerable resistance to thermal shock, enabling them to withstand sudden temperature variations without sustaining any cracks or fractures. To sum up, opting for insulating fire bricks proves to be a trustworthy and efficient solution for heat treatment furnace insulation.

- Q: Can insulating fire bricks be used as a lining for kiln cars?

- Indeed, insulating fire bricks exhibit remarkable thermal insulation qualities, rendering them appropriate for utilization as linings in kiln cars. These bricks are specifically engineered to withstand elevated temperatures without experiencing any fractures or disintegration, thereby establishing them as an optimal option for securing kiln cars. Furthermore, their lightweight composition facilitates convenient handling and installation, thereby diminishing the overall weight and energy consumption of the kiln. Consequently, insulating fire bricks effectively supply insulation and safeguard kiln cars, significantly enhancing their efficiency and longevity.

- Q: Can insulating fire bricks be used to build pizza ovens?

- Yes, insulating fire bricks can be used to build pizza ovens. Insulating fire bricks are known for their high heat resistance and low thermal conductivity, making them a suitable material for constructing pizza ovens that require high temperatures for efficient cooking. These bricks can help retain heat and distribute it evenly, resulting in a well-insulated and efficient pizza oven.

- Q: Are insulating fire bricks suitable for use in cement plants?

- Yes, insulating fire bricks are suitable for use in cement plants. They are commonly used in high-temperature applications, such as kilns and furnaces, due to their excellent thermal insulation properties and ability to withstand extreme heat. Insulating fire bricks can help optimize energy efficiency, reduce heat loss, and provide a more controlled and stable environment in cement plants.

- Q: Are insulating fire bricks resistant to flame impingement?

- Yes, insulating fire bricks are resistant to flame impingement.

- Q: What's the price of lightweight refractory bricks?

- In addition, general price comparisons are meaningless and need to be based on the use of demand = quality of products. After all, good quality is the driving force of continuous production.

- Q: Can insulating fire bricks be used in residential applications?

- Yes, insulating fire bricks can be used in residential applications. They are commonly used in residential fireplaces, wood-burning stoves, and pizza ovens to provide insulation and increase energy efficiency. Their high heat resistance and insulating properties make them suitable for these applications.

- Q: Can insulating fire bricks be used in high-temperature insulation panels?

- Yes, insulating fire bricks can be used in high-temperature insulation panels. Insulating fire bricks are designed to withstand high temperatures and provide excellent thermal insulation. They are made from lightweight refractory materials that have low thermal conductivity, allowing them to effectively reduce heat transfer. These bricks can be used in various applications, including furnaces, kilns, and high-temperature insulation panels. They are capable of withstanding temperatures up to 3000°F (1650°C) and can effectively retain heat, making them an ideal choice for high-temperature insulation panels.

- Q: Why does the water drop first and then rise when the boiler fires?

- This is the reason for the zero water level gauge line below the center line of the drum. Under normal conditions for water and evaporation is balanced, after the fire, reduce the amount of steam water mixture into the drum in the evaporation decreased rapidly, reduce the volume of water bubbles, sudden contraction, drum water level decreased rapidly. But not to water change or increase (automatic), water balance is broken, the water level will rise rapidly.

- Q: Can insulating fire bricks be used in combination with other insulation materials?

- Yes, insulating fire bricks can be used in combination with other insulation materials. They can be used as a primary insulation layer or in conjunction with other materials such as ceramic fiber insulation or refractory coatings to enhance insulation efficiency and achieve higher temperature resistance. This combination of insulation materials can provide better thermal insulation properties and increased energy efficiency in various applications such as furnaces, kilns, and high-temperature industrial processes.

Send your message to us

Insulating Fire Brick - Lightweight for Steel Pipe

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords