Insulating Fire Brick - Lightweight Insulating Brick

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t

- Supply Capability:

- 2000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

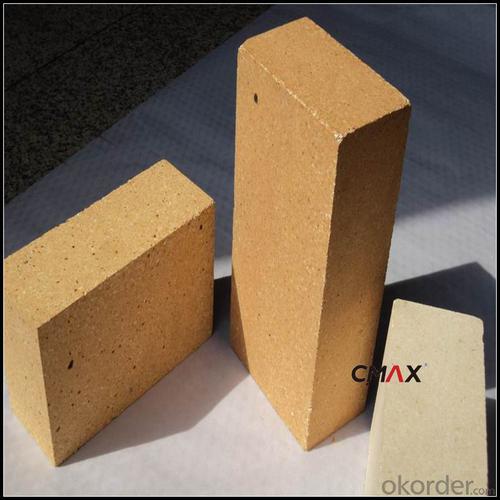

Light Weight Insulating Brick

CMAX insulating firebricks are classified under temperature between 1300℃ to 1700℃, manufactured from high purity alumina clay.

Light Weight Insulating Brick Features

Light weight and low thermal conductivity

Low heat storage

Low iron and impurities

High thermal shock resistance

Light Weight Insulating Brick Application

Hot air duct ling

Shuttle kiln with high gas velocity

Laboratory furnace

Kiln car insulation

Light Weight Insulating Brick Data Sheet

Classification Temperature (℉/℃) | 3000/1650 |

Bulk Density (g/cm3 ) | ≤1.0 |

Thermal Conductivity | |

800℃, W/m.K | ≤0.39 |

1000℃, W/m.K | ≤0.43 |

1200℃, W/m.K | ≤0.48 |

Reheating Linear Change (%) | 1550℃×12h |

≤0.9 | |

Chemical Composition (%) | |

Al2O3 | ≥75 |

Fe2O3 | ≤0.5 |

Packaging & Shipping

Packaging Details:Be packed in fumigated wooden pallets

Delivery Detail: 30 days after order

Our Services

Optimum solution and product supply of refractories for high temperature industries, such as iron steel, non-ferrous, petrochemical and building materials.

Engineering design, contract and consult for refractories, and civil architecture design.

Research, development, manufacture and sale of superhard materials.

R&D, manufacture and sale of special packing materials for export.

Inspection, supervision and arbitration of refractories.

Consultation and services in refractories information.

Training and cultivation of high-level talents in refractories profession

Sales Network

Company Information

CNBM (China National Building Material) Group is the largest comprehensive building materials group in China that in integrate scientific research, manufacturing and logistics into one entity. The largest building materials and equipment specialists in China. Upon State Council approval, today CNBM owned more than 300 subordinate manufacturing factories and servicing companies. There are 6 fully owned public listed companies and 11 partially owned with substantial shares public listed companies. In many of these fields, CNBM is playing the leading role in the building industry in the country.

FAQ

1. Which products do you have?

We have all kinds of refractory brick, castable, mortar, cement, ceramic fiber products, etc.

Or you could browse our products to choose what you need.

2. Can you give me a brief introduction of the application of your products?

We are mainly specializing in the refractory materials in iron and steel, cement, glass, ceramics, petrochemical, electric power Industry, etc.

3. If I need your offer, what information do you need?

In order to choose suitable products, it will be appreciated to provide us the information, such us specification, technical data, order quantity, products application etc. If any question, please contact us freely.

- Q: What is a JQK composite lightweight thermal insulation brick?

- Its characteristic is waterproof and heat insulation, thermal insulation performance, strong decoration, waterproof effect is good, and good weathering resistance, long service life, the whole system of simple construction, low cost, is a new type of inverted waterproof and insulation structure of the current system state key application.

- Q: Are insulating fire bricks suitable for use in autoclaves?

- No, insulating fire bricks are not suitable for use in autoclaves. Autoclaves require materials that can withstand high temperatures and pressure, while insulating fire bricks are designed for insulation purposes and may not have the necessary strength and durability.

- Q: Can insulating fire bricks be painted or coated?

- Insulating fire bricks can be painted or coated, but it is important to use high-temperature paint or coating specifically designed for use with these bricks to ensure durability and fire resistance.

- Q: Do insulating fire bricks require any special insulation blankets or jackets?

- Insulating fire bricks (IFBs) are designed to have excellent insulating properties, so they generally do not require any special insulation blankets or jackets. However, depending on the specific application and environment, additional insulation may be needed. If the IFBs are exposed to high temperatures or extreme thermal conditions, it may be beneficial to use insulation blankets or jackets to further enhance their insulation capabilities and protect them from damage. These additional insulation materials can help reduce heat loss, increase energy efficiency, and extend the lifespan of the IFBs. Therefore, while not always necessary, it is worth considering using insulation blankets or jackets in certain situations to optimize the performance of insulating fire bricks.

- Q: Can insulating fire bricks be used in ladles and tundishes?

- Insulating fire bricks prove to be suitable for ladles and tundishes as they are specifically designed to offer high-temperature insulation and thermal stability. These bricks are essential in applications where heat retention plays a pivotal role. Ladles and tundishes are extensively utilized in the steel and foundry sectors for the transportation and pouring of molten metal. By utilizing insulating fire bricks in these vessels, one can effectively minimize heat loss and maintain the desired temperature of the metal. Moreover, these bricks exhibit resilience towards thermal shock and chemical corrosion, which are common obstacles in such extreme temperature environments. Consequently, the utilization of insulating fire bricks in ladles and tundishes ultimately enhances energy efficiency, reduces heat loss, and improves the overall performance and lifespan of these vital pieces of equipment in the metal processing industry.

- Q: Are insulating fire bricks resistant to alkali attack?

- Insulating fire bricks generally possess resistance to alkali attack. They are composed of high-temperature refractory materials and are engineered to endure extreme temperatures and chemical surroundings. Alkalis typically corrode and deteriorate certain substances, but insulating fire bricks are specifically devised to withstand this form of chemical assault. They possess limited porosity and a compact structure, thereby thwarting alkalis from infiltrating the brick's surface. Furthermore, the refractory materials employed in these bricks possess a high melting point and exhibit chemical inertness, rendering them ideal for situations where exposure to alkali is a concern. However, it is crucial to acknowledge that the resistance of insulating fire bricks to alkali attack may vary depending on the brick's composition, manufacturing process, as well as the concentration and duration of alkali exposure. Thus, it is always advisable to consult the manufacturer or supplier for comprehensive details regarding the alkali resistance of their specific insulating fire bricks.

- Q: Are insulating fire bricks resistant to electrical conductivity?

- Yes, insulating fire bricks are resistant to electrical conductivity. These bricks are made from materials that have low electrical conductivity, such as ceramic fibers or insulating refractory materials. The main purpose of insulating fire bricks is to provide thermal insulation, making them ideal for applications where high temperatures need to be contained. As a result of their low electrical conductivity, insulating fire bricks do not conduct electricity and are used to line electrical furnaces, kilns, and other high-temperature equipment where electrical insulation is required.

- Q: Can insulating fire bricks be used in the construction of boilers for steam generation?

- Yes, insulating fire bricks can be used in the construction of boilers for steam generation. Insulating fire bricks have excellent heat insulation properties, making them suitable for use in high-temperature applications such as boilers. They help to minimize heat loss, improve energy efficiency, and ensure safe and efficient steam generation.

- Q: Can insulating fire bricks be used in the construction of heat exchangers?

- Yes, insulating fire bricks can be used in the construction of heat exchangers. These bricks are designed to withstand high temperatures and have excellent insulating properties, making them suitable for heat exchanger applications where heat retention and insulation are important.

- Q: Can insulating fire bricks be used in the construction of smelters or foundries?

- Yes, insulating fire bricks can be used in the construction of smelters or foundries. Insulating fire bricks have excellent thermal insulation properties and can withstand high temperatures, making them suitable for lining the walls and floors of smelters or foundries. They help to retain heat, improve energy efficiency, and protect the surrounding structures from extreme temperatures.

Send your message to us

Insulating Fire Brick - Lightweight Insulating Brick

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t

- Supply Capability:

- 2000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords