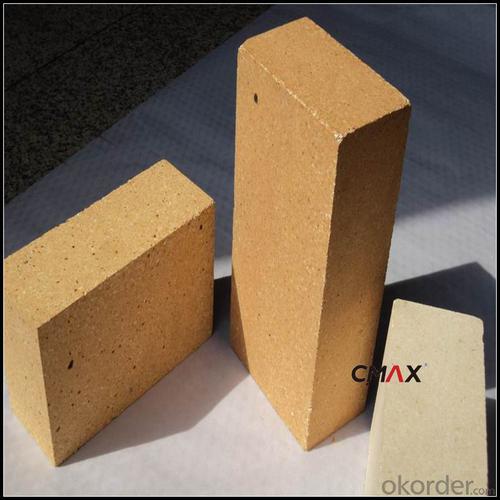

High Temperature Insulating Fire Brick

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t

- Supply Capability:

- 2000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Insulating Brick

CMAX insulating firebricks are classified under temperature between 1300℃ to 1700℃, manufactured from high purity alumina clay.

High strength clay heat insulation refractory brick use high quality hollow drift beads and super clay as the main raw material, through high heat sintering. With the characteristics of high strength, low thermal conductivity, is suitable for industry kiln under 1350 ℃ heat insulation layer and the lining.

Insulating Brick Features

1)Excellent wear resistance

2)Good impact resistance.

3)Good corrosion resistantce.

4)Good adherence

Insulating Brick Application

1)Excellent wear resistance and long working life.

2)Good impact resistance.

3)Good corrosion resistance.

4)Good thermal shock resistance

5)High wear resistantance

6)Smooth surface and good adherence resistance.

Insulating Brick Data Sheet

Classification Temperature (℉/℃) | 3000/1650 |

Bulk Density (g/cm3 ) | ≤1.0 |

Thermal Conductivity | |

800℃, W/m.K | ≤0.39 |

1000℃, W/m.K | ≤0.43 |

1200℃, W/m.K | ≤0.48 |

Reheating Linear Change (%) | 1550℃×12h |

≤0.9 | |

Chemical Composition (%) | |

Al2O3 | ≥75 |

Fe2O3 | ≤0.5 |

Packaging & Shipping

Packaging Details:Be packed in fumigated wooden pallets

Delivery Detail: 30 days after order

Our Services

Optimum solution and product supply of refractories for high temperature industries, such as iron steel, non-ferrous, petrochemical and building materials.

Engineering design, contract and consult for refractories, and civil architecture design.

Research, development, manufacture and sale of superhard materials.

R&D, manufacture and sale of special packing materials for export.

Inspection, supervision and arbitration of refractories.

Consultation and services in refractories information.

Training and cultivation of high-level talents in refractories profession

Sales Network

Company Information

CNBM (China National Building Material) Group is the largest comprehensive building materials group in China that in integrate scientific research, manufacturing and logistics into one entity. The largest building materials and equipment specialists in China. Upon State Council approval, today CNBM owned more than 300 subordinate manufacturing factories and servicing companies. There are 6 fully owned public listed companies and 11 partially owned with substantial shares public listed companies. In many of these fields, CNBM is playing the leading role in the building industry in the country.

FAQ

1. Which products do you have?

We have all kinds of refractory brick, castable, mortar, cement, ceramic fiber products, etc.

Or you could browse our products to choose what you need.

2. Can you give me a brief introduction of the application of your products?

We are mainly specializing in the refractory materials in iron and steel, cement, glass, ceramics, petrochemical, electric power Industry, etc.

3. If I need your offer, what information do you need?

In order to choose suitable products, it will be appreciated to provide us the information, such us specification, technical data, order quantity, products application etc. If any question, please contact us freely.

- Q: Can insulating fire bricks be used in the construction of boilers for power plants?

- Yes, insulating fire bricks can be used in the construction of boilers for power plants. These bricks have excellent insulating properties, which help to retain heat and increase energy efficiency in the boilers. Additionally, their lightweight nature reduces the overall weight of the construction, making them a suitable choice for power plant boilers.

- Q: Can insulating fire bricks be used in high-velocity gas flow applications?

- Yes, insulating fire bricks can be used in high-velocity gas flow applications. Insulating fire bricks are designed to have excellent thermal insulation properties, low thermal conductivity, and high resistance to temperature fluctuations. These characteristics make them suitable for various high-temperature applications, including high-velocity gas flow environments. When exposed to high-velocity gas flow, insulating fire bricks can maintain their structural integrity and insulation properties, providing effective thermal insulation and protection. They are often used in applications such as kilns, furnaces, boilers, and other industrial equipment where high-velocity gas flow is present. However, it is important to consider the specific requirements and characteristics of the gas flow in the application. Factors such as temperature, pressure, and chemical composition of the gas should be taken into account to ensure that the insulating fire bricks are compatible and can withstand the conditions. In summary, insulating fire bricks can be used in high-velocity gas flow applications due to their thermal insulation properties and resistance to temperature fluctuations. However, it is crucial to consider the specific requirements and characteristics of the gas flow to ensure proper compatibility and performance.

- Q: Can insulating fire bricks be used in the construction of hearths?

- Yes, insulating fire bricks can be used in the construction of hearths. These bricks are designed to withstand high temperatures and provide excellent insulation, making them ideal for use in hearth construction. They help to retain heat and prevent the loss of energy, ensuring efficient and effective heating.

- Q: Are insulating fire bricks suitable for use in steel manufacturing plants?

- Insulating fire bricks are a suitable choice for steel manufacturing plants. Their excellent thermal properties, including high heat resistance and low thermal conductivity, make them ideal for high-temperature environments like steel manufacturing plants. These bricks can endure the extreme heat generated during steel production processes such as melting, casting, and forging. Furthermore, they assist in conserving energy by minimizing heat loss, thereby enhancing the overall efficiency of the plant. Additionally, they possess considerable mechanical strength and can withstand the physical stresses and strains associated with steel manufacturing operations. In summary, incorporating insulating fire bricks in steel manufacturing plants can enhance safety, boost productivity, and improve energy efficiency.

- Q: How do insulating fire bricks compare to other types of refractory materials?

- Insulating fire bricks have a higher insulating capability compared to other types of refractory materials. They are lighter in weight, have lower thermal conductivity, and provide better energy efficiency. However, they may have slightly lower strength and durability compared to dense fire bricks or other refractory materials.

- Q: Can insulating fire bricks be used for insulation in aluminum smelters?

- Insulating fire bricks are capable of being utilized for insulation in aluminum smelters. Crafted from unique lightweight materials possessing exceptional insulation properties, these bricks are an optimal choice for high-temperature insulation needs. With aluminum smelters operating at exceedingly elevated temperatures, insulating fire bricks possess the ability to effectively endure and retain heat, thereby averting heat loss and enhancing energy efficiency. Moreover, these bricks exhibit resistance to thermal shock, a prevalent phenomenon in smelting procedures, rendering them highly appropriate for employment in aluminum smelters. Additionally, insulating fire bricks can establish a protective barrier, mitigating the risk of heat damage to neighboring structures and equipment. Consequently, implementing insulating fire bricks for insulation in aluminum smelters can augment thermal efficiency, diminish energy consumption, and guarantee a secure and proficient smelting process.

- Q: Are insulating fire bricks easy to cut and shape?

- Yes, insulating fire bricks are relatively easy to cut and shape. They are made from lightweight refractory materials such as ceramic fibers, which make them easier to handle compared to traditional fire bricks. Insulating fire bricks can be cut and shaped using common tools such as a saw, knife, or chisel. Their lightweight nature also makes them easier to maneuver and position, allowing for more precise cuts and shapes. Additionally, insulating fire bricks can be easily drilled or carved to create openings or specific designs if needed. Overall, their ease of cutting and shaping makes insulating fire bricks a convenient choice for various applications in construction, insulation, and fireproofing.

- Q: Can insulating fire bricks be used in the construction of hearths?

- Yes, insulating fire bricks can be used in the construction of hearths. Insulating fire bricks are designed to withstand high temperatures, making them an excellent choice for hearth construction. They have low thermal conductivity, which helps to retain heat and prevent the transfer of heat to the surrounding areas. This makes them ideal for creating a well-insulated and efficient hearth. Additionally, insulating fire bricks are lightweight and easy to handle, making them convenient for construction purposes. Overall, insulating fire bricks are a reliable and practical option for building hearths.

- Q: What are the sizes of lightweight thermal insulation bricks?

- The production of material ordinary lightweight insulating refractory brick with fireclay and high alumina high strength bead brick

- Q: What is the recommended method for installing insulating fire bricks?

- The recommended method for installing insulating fire bricks is to first prepare the surface by cleaning it thoroughly and ensuring it is dry. Then, apply a thin layer of refractory mortar to the surface where the bricks will be placed. Carefully lay the bricks in a tight, staggered pattern, pressing them firmly into the mortar. Use a level to ensure they are properly aligned. Allow the mortar to dry completely before subjecting the bricks to heat.

Send your message to us

High Temperature Insulating Fire Brick

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t

- Supply Capability:

- 2000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords