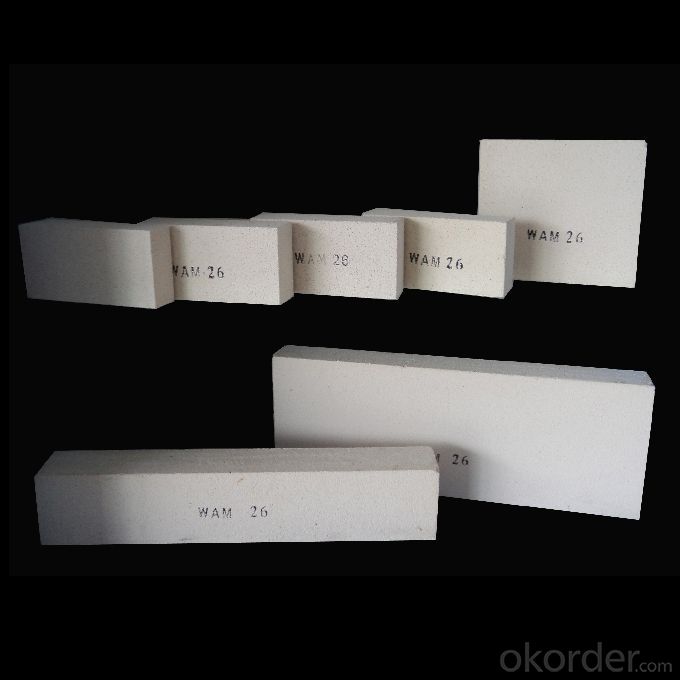

Insulating Fire Brick - Refractory Mullite GJM32

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information

CMAX insulating firebricks are classified under temperature between 1300℃ to 1700℃, manufactured from high purity alumina clay.

1. Lower content of iron, alkaline and impurities, good high temperature properties.

2. Homogeneous structure, light weight, energy saving because lower heat storage in the furnace during cooling cycles.

3. High strength, good thermal shock resistance under high temperature.

4. Precise sizes due to grinding and shaping after sintering, which meets the requirement of construction.

5. Max service temp: Up to 1730C (3160F)

Feature

Light weight and low thermal conductivity

Low heat storage

Low iron and impurities

High thermal shock resistance

Application

CMAX insulating firebricks can be used as a hot face lining directly exposed to the heat or as a backup insulation layer in iron and steel mills, non-ferrous foundries, petrochemical, ceramic, glass.

ITEM | GJM30 | GJM28 | GJM26 | GJM23 |

Classification Temperature, ℉/℃ | 3000/1650 | 2800/1540 | 2600/1430 | 2300/1260 |

Bulk Density,g/cm³ | ≤1.0 | ≤0.9 | ≤0.8 | ≥0.5 |

Reheating Linear Change, % | ≤0.9 (1550℃,12 h) | ≤0.8 (1510℃,12 h) | ≤0.7 (1410℃,12 h) | ≤0.5 (1230℃,12 h) |

Al2O3 Content, % | ≥75 | ≥65 | ≥55 | ≥45 |

Fe2O3 Content, % | ≤0.5 | ≤0.6 | ≤0.7 | ≤1.0 |

Thermal Conductivity: | ||||

800℃, w/m.k | ≤0.39 | ≤0.37 | ≤0.35 | ≤0.18 |

1000℃, w/m.k | ≤0.43 | ≤0.41 | ≤0.39 | ≤0.20 |

1200℃, w/m.k | ≤0.48 | ≤0.46 | ≤0.43 | --- |

- Q: How long do insulating fire bricks typically last?

- Insulating fire bricks typically last for several years, with an average lifespan of 10 to 20 years.

- Q: Are insulating fire bricks resistant to spalling?

- Insulating fire bricks exhibit resistance to spalling. These bricks are specially engineered to endure elevated temperatures and thermal shock, rendering them highly immune to spalling. Spalling indicates the fracturing and fracturing of bricks owing to exposure to extreme heat. Composed of superior refractory materials with low thermal conductivity, insulating fire bricks restrict heat transmission and diminish spalling hazards. Moreover, these bricks boast a remarkable melting point, rendering them excellently suited for applications demanding high temperatures. Consequently, insulating fire bricks find widespread application in furnaces, kilns, and other environments characterized by elevated temperatures, where spalling poses a significant concern.

- Q: Can insulating fire bricks be used in the construction of melting furnaces?

- Insulating fire bricks can indeed be utilized in the construction of melting furnaces. These bricks are specifically designed to withstand high temperatures while possessing excellent thermal conductivity. Their primary purpose is to minimize heat loss and conserve energy, rendering them highly suitable for melting furnaces. Additionally, these bricks are lightweight and easily manageable, providing convenience during construction. They are also capable of effectively retaining heat and maintaining a steady furnace temperature, thus ensuring efficient melting and casting processes. Moreover, insulating fire bricks exhibit resistance to chemical corrosion and mechanical stress, showcasing their durability and reliability for long-term use in melting furnaces. In conclusion, considering their thermal properties, ease of use, and durability, insulating fire bricks are a fitting choice for constructing melting furnaces.

- Q: Can insulating fire bricks be used in biomass boilers?

- Yes, insulating fire bricks can be used in biomass boilers. These bricks are designed to withstand high temperatures and provide excellent insulation, making them suitable for use in biomass boilers where heat retention is crucial for efficient combustion.

- Q: Can insulating fire bricks be used in the construction of refractory coatings?

- Yes, insulating fire bricks can be used in the construction of refractory coatings. Insulating fire bricks are designed to have low thermal conductivity, making them suitable for insulating applications. When used as a component in refractory coatings, they can help to enhance the insulation properties and provide thermal protection.

- Q: Can insulating fire bricks be used in rotary kilns?

- Rotary kilns can indeed utilize insulating fire bricks. These bricks are specifically designed to possess low thermal conductivity, enabling them to withstand high temperatures while minimizing heat loss. Consequently, they are well-suited for employment in rotary kilns, which are utilized across various industries for processes like calcination, sintering, and roasting. The application of insulating fire bricks within rotary kilns effectively contains the internally generated heat, resulting in enhanced energy efficiency and cost savings. Moreover, these bricks' insulating properties aid in reducing the temperature on the kiln's outer surface, thereby ensuring a safer working environment for operators. Ultimately, insulating fire bricks serve as an ideal choice for rotary kilns, offering remarkable thermal insulation and contributing to the kiln's overall performance and durability.

- Q: Can insulating fire bricks be used in boilers for residential heating?

- Insulating fire bricks can indeed be utilized for residential heating boilers. These bricks are specifically engineered to endure elevated temperatures and offer superior thermal insulation properties. Their utilization in boiler and furnace construction is widespread due to their remarkable heat retention capabilities and ability to prevent heat dissipation. Consequently, the incorporation of these bricks aids in enhancing the energy efficiency of the boiler system by minimizing heat transfer to the surroundings, resulting in more effective heating and reduced energy consumption. Furthermore, the durability and resistance to thermal shock exhibited by insulating fire bricks make them ideal for withstanding the intense temperatures and rapid temperature fluctuations typically encountered in boilers. Consequently, their implementation in residential heating boilers serves to enhance both performance and energy efficiency.

- Q: Can insulating fire bricks be used in crucibles?

- Crucibles do not allow the use of insulating fire bricks. Insulating fire bricks are primarily meant for insulation purposes in kilns, furnaces, and fireplaces, where low thermal conductivity is desirable. On the other hand, crucibles necessitate materials with high thermal conductivity and resistance to endure the intense heat and chemical reactions involved in processes like metal melting or refining, conducting high-temperature experiments, or performing chemical reactions. Consequently, crucibles are generally constructed using materials like graphite, clay, or ceramic, which can withstand the extreme conditions and facilitate efficient heat transfer.

- Q: Can insulating fire bricks be used in thermal oxidizers?

- Insulating fire bricks are indeed applicable for thermal oxidizers. These bricks are specifically designed to possess low thermal conductivity, enabling them to effectively diminish heat transfer and conserve energy in high-temperature scenarios. Thermal oxidizers, on the other hand, are utilized as devices for treating industrial exhaust gases through the process of oxidizing pollutants at elevated temperatures. By incorporating insulating fire bricks into the construction of thermal oxidizers, the system can confine heat within, ensuring efficient combustion while minimizing heat loss to the surrounding environment. Consequently, this not only enhances the overall thermal efficiency of the thermal oxidizer but also aids in decreasing energy consumption and operational expenses. Furthermore, insulating fire bricks possess remarkable resistance against thermal shock and display exceptional insulating properties, rendering them suitable for the challenging and rigorous conditions commonly encountered in thermal oxidizers.

- Q: Can insulating fire bricks be used in the construction of hot water boilers?

- Indeed, hot water boilers can utilize insulating fire bricks for their construction. These bricks are specifically engineered to endure extreme temperatures and offer exceptional thermal insulation. Their low thermal conductivity effectively minimizes heat dissipation, thereby enhancing the overall energy efficiency of the boiler. Furthermore, these bricks exhibit remarkable resistance to thermal shock, rendering them suitable for the intense heat generated within hot water boilers. Moreover, their lightweight composition facilitates effortless handling and installation in the boiler, rendering them a favored option for insulation in the construction of hot water boilers.

Send your message to us

Insulating Fire Brick - Refractory Mullite GJM32

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords