Insulating Fire Brick - Refractory JM Mullite Insulation Brick ZDC-32

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Refractory Mullite Insulating Fire Brick JM 23

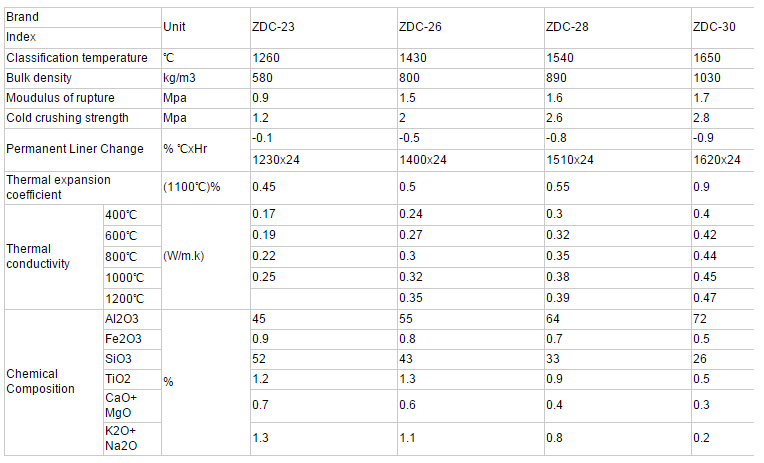

OKORDER Series Insulating Bricks

OKORDER series insulating bricks are a kind of highly efficient, energy saving, low-carbon, environmental protection advanced products which are manufactured according to ASTM standard. OKORDER series products are the best lining and insulation materials in all types of industrial furnaces in the field of Metallurgy, Aluminum, Petrochemical, Ceramics, Power and Glass. They can be applied as heat insulation or no-melt erosion parts of the working layer. The products have been widely used in the following furnaces and achieved satisfactory results.

Application of Insulating Bricks

Metallurgy industry: Blast furnace, Hot blast stove, Reheating furnace, etc.

Petrochemical industry: Ethylene cracking furnace, Hydrogen production furnace, Primary reformer furnace, Reheating furnace, etc.

Ceramics Industry: Roller kiln, Pusher kiln, etc.

Glass industry: Glass furnace regenerator, etc.

Carbon Industry: Carbon roaster, etc.

Aluminum electrolytic industry: aluminum reduction cells,etc.

Other industries: Tunnel kiln, Shuttle kiln, etc.

Advantages of Insulating Bricks

Low Thermal Conductivity: More porosity brings excellent insulation effect, energy saving.

High Crushing Strength: High crushing strength under thermal state, volume stability.

Low Heat Storage: Little thermal storage when absorb more heat, energy saving effect is obvious.

High Purity: Low content of iron, alkaline and metal impurities.

Accurate Dimension: Precise brick size by machining, cutting and grinding special shapes, expediting bricklaying.

Picture of Insulating Bricks

FAQ

1. Which products do you have?

We have all kinds of refractory brick, castable, mortar, cement, ceramic fiber products, etc.

Or you could browse our products to choose what you need.

2. How do you control the products quality?

With strict quality control system throughout the materials selection and production process, our refractory and ceramic fiber products quality is effectively controlled to meet customer requirements.

From the raw materials selecting, our quality control begin. The quality certificates of raw materials are required and each batch will be tested before using. During production, the quality control are conducted by workers and then each piece will be sorted and examined by quality supervise.

3. Can you give me a brief introduction of the application of your products?

We are mainly specializing in the refractory materials in iron and steel, cement, glass, ceramics, petrochemical, electric power Industry, etc.

4. If I need your offer, what information do you need?

In order to choose suitable products, it will be appreciated to provide us the information, such us specification, technical data, order quantity, products application etc.

If any question, please contact us freely.

Application:

Insulation brick can be widely used for lining or insulation layers of various industrial furnaces and kilns in metallurgical industry, machine building industry, ceramic industry, chemical industry.

- Q: Material and making method of light insulating brick

- Material production of ordinary light insulating brick clay, high alumina high strength low iron bead brick, mullite, high aluminum light insulating refractory brick, diatomite insulating refractory brick.

- Q: How do insulating fire bricks help reduce heat loss through conduction?

- Insulating fire bricks are specifically designed to minimize the loss of heat through conduction by utilizing their unique properties. These bricks are manufactured using a special lightweight refractory material, such as ceramic fibers or a combination of high-alumina and silica, which possess a low thermal conductivity. The low thermal conductivity of insulating fire bricks serves to diminish the transfer of heat through conduction. When heat is applied to one side of the brick, the material's low thermal conductivity prevents the rapid flow of heat to the other side. Consequently, less heat is lost through the brick via conduction, leading to enhanced insulation and energy efficiency. Moreover, insulating fire bricks often exhibit a high level of porosity, which results in the formation of air pockets within the material. These air pockets function as barriers to heat transfer since air is a poor conductor of heat. By ensnaring air within the structure of the brick, insulating fire bricks effectively decelerate the movement of heat, further reducing heat loss through conduction. Additionally, insulating fire bricks possess a high melting point, enabling them to endure extreme temperatures without distorting or deteriorating. This characteristic guarantees that the bricks can proficiently insulate against heat transfer even in high-temperature environments, such as furnaces or kilns. In conclusion, insulating fire bricks aid in diminishing heat loss through conduction by virtue of their low thermal conductivity, high porosity, and high melting point. These bricks capably restrict the transmission of heat from one side to the other, thereby minimizing energy loss and enhancing insulation efficiency.

- Q: Can insulating fire bricks be used for insulation in smelters?

- Yes, insulating fire bricks can be used for insulation in smelters. Insulating fire bricks are specifically designed to withstand high temperatures and provide excellent thermal insulation. They are made from lightweight refractory materials that have low thermal conductivity, allowing them to effectively retain heat and minimize heat loss. This makes them ideal for use in smelters, where maintaining high temperatures is crucial for efficient metal smelting processes. Additionally, insulating fire bricks are resistant to chemical attack and mechanical stress, ensuring their durability and suitability for use in harsh smelting environments.

- Q: Can insulating fire bricks be used in the construction of incinerators?

- Yes, insulating fire bricks can be used in the construction of incinerators. These bricks are designed to withstand high temperatures and provide excellent thermal insulation, making them suitable for lining the walls, floors, and ceilings of incinerator chambers. Their insulating properties help to retain heat, improve energy efficiency, and protect the surrounding structures from excessive heat.

- Q: Do insulating fire bricks require any special anchors or supports for installation?

- Yes, insulating fire bricks typically do not require any special anchors or supports for installation. They are lightweight and can be easily stacked or laid in place without additional reinforcement.

- Q: Can insulating fire bricks be used for insulation in petrochemical plants?

- Insulating fire bricks have multiple applications, one of which is their use in petrochemical plants for insulation purposes. These bricks possess exceptional thermal properties, characterized by their low thermal conductivity and high resistance to heat transfer. These remarkable features render them suitable for deployment in high-temperature environments, such as petrochemical plants. In such settings, insulation plays a critical role in preventing heat loss and maintaining optimal operational conditions. Moreover, these bricks are not only lightweight but also possess robust mechanical strength. This facilitates their easy installation and ensures durability in industrial settings. Additionally, their resistance to chemical corrosion is a crucial attribute for petrochemical plants that handle a wide range of corrosive substances. Consequently, insulating fire bricks effectively fulfill the insulation requirements, thereby enhancing energy efficiency and promoting safety in petrochemical plants.

- Q: Can insulating fire bricks be used for chimney lining?

- Indeed, chimney lining can indeed benefit from the utilization of insulating fire bricks. These bricks are meticulously crafted to endure soaring temperatures and excel in heat retention. Their remarkable capacity for minimizing thermal conductivity effectively curbs heat dissipation, thereby enhancing the chimney's efficiency. Moreover, their impressive resistance to cracking and spalling renders them a resilient choice for lining. Nevertheless, it remains crucial to ascertain that the chosen insulating fire bricks align with the particular chimney type and adhere to the applicable local building codes and regulations.

- Q: Are insulating fire bricks easy to cut and shape?

- Yes, insulating fire bricks are relatively easy to cut and shape. They are made from lightweight refractory materials such as ceramic fibers, which make them easier to handle compared to traditional fire bricks. Insulating fire bricks can be cut and shaped using common tools such as a saw, knife, or chisel. Their lightweight nature also makes them easier to maneuver and position, allowing for more precise cuts and shapes. Additionally, insulating fire bricks can be easily drilled or carved to create openings or specific designs if needed. Overall, their ease of cutting and shaping makes insulating fire bricks a convenient choice for various applications in construction, insulation, and fireproofing.

- Q: Are insulating fire bricks resistant to carbon monoxide?

- Indeed, insulating fire bricks demonstrate a remarkable resistance to carbon monoxide. Tailored for enduring extreme temperatures, these bricks find common application in environments where they are likely to encounter both intense heat and corrosive agents, including carbon monoxide. The insulating nature of these bricks bestows upon them an exceptional ability to impede heat transfer, ensuring their structural integrity remains intact even in the presence of carbon monoxide and other combustible gases. This resistance to carbon monoxide renders insulating fire bricks a stellar choice for various settings like furnaces, kilns, and other high-temperature surroundings where the potential for carbon monoxide exposure looms.

- Q: Can insulating fire bricks be used in a refractory lining?

- Yes, insulating fire bricks can be used in a refractory lining. Insulating fire bricks are made from lightweight materials and have high insulating properties, which make them suitable for use in refractory linings to reduce heat loss and improve energy efficiency.

Send your message to us

Insulating Fire Brick - Refractory JM Mullite Insulation Brick ZDC-32

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords