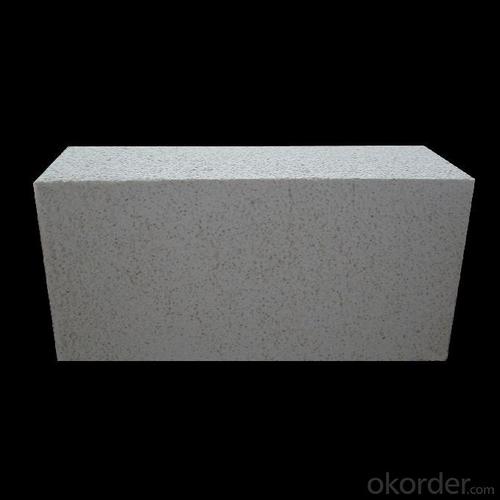

Insulating Fire Brick - Refractory Mullite Insulating Refractory Brick JM 42

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 20 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information

CMAX insulating firebricks are classified under temperature between 1300℃ to 1700℃, manufactured from high purity alumina clay.

1. Lower content of iron, alkaline and impurities, good high temperature properties.

2. Homogeneous structure, light weight, energy saving because lower heat storage in the furnace during cooling cycles.

3. High strength, good thermal shock resistance under high temperature.

Feature

Light weight and low thermal conductivity

Low heat storage

Low iron and impurities

Application of Insulating brick

Metallurgical Industry: blast furnace, hot blast furnace, heating furnace, etc..

Petrochemical Industry: ethylene cracking furnace, hydrogen furnace, the main furnace, heating furnace, etc..

Ceramic industry: roller kiln, kiln, etc..

Advantages of heat insulation brick

Low thermal conductivity: many air holes will bring good thermal insulation effect, energy saving.

High crushing strength: high crushing strength, volume stability.

Low heat storage: small heat storage, absorb more heat, energy-saving effect is obvious.

Technical Data

ITEM | GJM30 | GJM28 | GJM26 | GJM23 |

Classification Temperature, ℉/℃ | 3000/1650 | 2800/1540 | 2600/1430 | 2300/1260 |

Bulk Density,g/cm³ | ≤1.0 | ≤0.9 | ≤0.8 | ≥0.5 |

Reheating Linear Change, % | ≤0.9 (1550℃,12 h) | ≤0.8 (1510℃,12 h) | ≤0.7 (1410℃,12 h) | ≤0.5 (1230℃,12 h) |

Al2O3 Content, % | ≥75 | ≥65 | ≥55 | ≥45 |

Fe2O3 Content, % | ≤0.5 | ≤0.6 | ≤0.7 | ≤1.0 |

Thermal Conductivity: | ||||

800℃, w/m.k | ≤0.39 | ≤0.37 | ≤0.35 | ≤0.18 |

1000℃, w/m.k | ≤0.43 | ≤0.41 | ≤0.39 | ≤0.20 |

1200℃, w/m.k | ≤0.48 | ≤0.46 | ≤0.43 | --- |

Insulating brick

- Q: Can insulating fire bricks be used in chimneys?

- Insulating fire bricks are indeed suitable for chimneys. Their purpose lies in enduring high temperatures, rendering them an excellent option for lining chimneys. Not only do they possess superb thermal insulation properties, thus minimizing heat loss and enhancing chimney efficiency, but they are also lightweight and simple to install. Nonetheless, it is crucial to acknowledge that insulating fire bricks may not be suitable for every chimney type. To ascertain the appropriate materials for your individual chimney requirements, consulting a professional or chimney specialist is highly recommended.

- Q: Can insulating fire bricks be used for insulation in cold storage facilities?

- Indeed, insulating fire bricks have the capability to be utilized for insulation purposes within cold storage facilities. These bricks are fashioned from lightweight materials possessing exceptional insulating properties, such as ceramic or refractory fibers. Their low thermal conductivity allows for the efficient prevention of heat transfer and the maintenance of a consistent temperature inside the cold storage facility. Moreover, these bricks exhibit resistance to extreme cold temperatures and possess the ability to endure thermal shock, rendering them fitting for employment in cold storage applications. Furthermore, insulating fire bricks possess durability and are capable of providing long-term insulation, thereby reducing energy consumption and preserving the desired temperature required for storing perishable goods.

- Q: Can insulating fire bricks be used in cement kilns?

- Yes, insulating fire bricks can be used in cement kilns. Insulating fire bricks are designed to have low thermal conductivity, which makes them ideal for insulating high-temperature environments such as cement kilns. These bricks can help to reduce heat loss and improve energy efficiency in the kiln. Additionally, their lightweight nature makes them easier to handle and install in the kiln. However, it is important to ensure that the insulating fire bricks selected are compatible with the specific operating conditions and requirements of the cement kiln to ensure optimal performance and longevity.

- Q: Are insulating fire bricks easy to cut and shape?

- Yes, insulating fire bricks are relatively easy to cut and shape. They are made from lightweight refractory materials such as ceramic fibers, which make them easier to handle compared to traditional fire bricks. Insulating fire bricks can be cut and shaped using common tools such as a saw, knife, or chisel. Their lightweight nature also makes them easier to maneuver and position, allowing for more precise cuts and shapes. Additionally, insulating fire bricks can be easily drilled or carved to create openings or specific designs if needed. Overall, their ease of cutting and shaping makes insulating fire bricks a convenient choice for various applications in construction, insulation, and fireproofing.

- Q: Can insulating fire bricks be used in the construction of glass slump molds?

- Yes, insulating fire bricks can be used in the construction of glass slump molds. Insulating fire bricks are made of lightweight materials that are able to withstand high temperatures, making them suitable for use in kilns and other heat-intensive applications. When constructing a glass slump mold, it is important to have a material that can withstand the heat of the glass as it slumps and takes shape. Insulating fire bricks provide the necessary insulation and heat resistance required for this process. They can be cut and shaped to fit the desired mold design and can withstand repeated firings without degrading or crumbling. Overall, insulating fire bricks are a reliable and durable option for constructing glass slump molds.

- Q: Can insulating fire bricks be used in the construction of glass bottle production furnaces?

- Yes, insulating fire bricks can be used in the construction of glass bottle production furnaces. Insulating fire bricks have high thermal resistance and low thermal conductivity, making them ideal for use in furnaces where high temperatures need to be maintained. Additionally, they help to reduce heat loss, improve energy efficiency, and provide insulation against heat transfer, which is crucial in glass bottle production.

- Q: Are insulating fire bricks suitable for use in the construction of incinerators?

- Yes, insulating fire bricks are suitable for use in the construction of incinerators. Insulating fire bricks have excellent thermal insulation properties, allowing them to withstand high temperatures and efficiently retain heat. This makes them ideal for lining the walls and floors of incinerators, as they help to contain and direct heat, ensuring proper combustion while reducing heat loss. Additionally, insulating fire bricks are resistant to chemical attacks and can withstand the corrosive environment found in incinerators, making them a reliable choice for this application.

- Q: Can insulating fire bricks be used in ladle covers?

- Ladle covers can indeed incorporate insulating fire bricks, which are specifically designed with low thermal conductivity to effectively insulate and retain heat. These bricks find their application in foundries and other high-temperature industries to maintain the heat of molten metal or other materials and prevent heat loss. By employing insulating fire bricks in ladle covers, heat retention is enhanced, resulting in improved energy efficiency and reduced fuel consumption. Furthermore, these bricks exhibit high refractory properties, enabling them to withstand the extreme temperatures and thermal shock encountered by ladles. All in all, insulating fire bricks prove to be an exceptional choice for ladle covers, contributing to temperature stability and heat preservation.

- Q: Is it possible to cut insulating fire bricks to fit custom shapes?

- Cutting insulating fire bricks to fit custom shapes is indeed possible. These bricks, composed of lightweight materials like ceramic fiber, can be easily cut or shaped using a range of tools. Cutting methods typically involve a saw, knife, or even a hot wire cutter. However, it is crucial to prioritize safety precautions and wear protective gear while undertaking this task. Dust and sharp edges may be produced during the cutting process. By employing suitable tools and techniques, it becomes achievable to tailor insulating fire bricks to any desired custom shape.

- Q: Can insulating fire bricks be used for kiln furniture?

- Indeed, kiln furniture can be fashioned from insulating fire bricks. These bricks are specifically engineered to endure extreme temperatures and are frequently employed in industrial kilns and furnaces. Their exceptional thermal insulation characteristics render them perfect for crafting kiln furniture like shelves, posts, and supports. The insulating attributes of these bricks aid in the uniform dispersion of heat throughout the kiln, guaranteeing consistent heating of the items being fired. Furthermore, insulating fire bricks possess a lightweight composition and are effortlessly manageable, thereby making them a convenient selection for kiln furniture.

Send your message to us

Insulating Fire Brick - Refractory Mullite Insulating Refractory Brick JM 42

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 20 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords