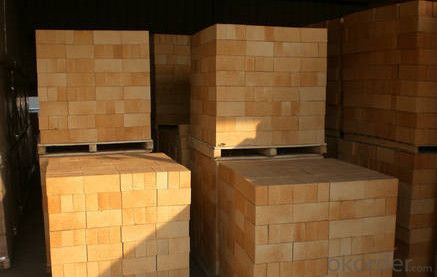

Insulating Fire Brick:Low Conductivity Mullite Refractory Brick

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

CNBM conforms strictly to the requirements of ISO 9000 quality control system during the production. MSDS is also available if you want. The thermal insulation fire clay brick meet with the requirements of ASTM & JIS standards. So pls stay cool with our quality.

Brief discription for Alumina Fire Brick

CNBM Alumina Fire Brick are classified according to alumina content ranging from 48% to 90%.

CNBM Alumina Fire Brick are commonly used in blast furnace, hot blast furnace, the roof of electric furnace, teeming ladle, rotary kiln, regenerator, etc.

Brief features for Alumina Fire Brick

◆Low thermal conductivity

◆Excellent acid and base slagging resistance

◆High refractoriness

◆Excellent thermal shock resistance

◆Excellent mechanical strength

◆Good spalling resistance and wear resistance.

◆Good corrosion resistance.

◆High-temperature creep rate is quite low.

◆Good volume stability at high temperature.

◆Low bulk density, low thermal conductivity, good thermal insulation performance.

Technical data for high aluminia bricks

ITEM | UAL48 | UAL55 | UAL65 | UAL75 | UAL80 | UAL85 | ALP80 |

Refractoriness, ℃ | 1750 | 1770 | 1790 | 1790 | 1810 | 1810 | 1810 |

Apparent Porosity,% | 22 | 22 | 23 | 23 | 20 | 20 | 18 |

C.C.S, Mpa | 39 | 44 | 49 | 53 | 55 | 60 | 100 |

Refractories Under Load (0.2Mpa),℃ | 1420 | 1470 | 1500 | 1520 | 1500 | 1520 | 1550 |

Reheating Linear Change,% | 1450℃x2h 0.1~-0.4 | 1500℃x2h 0.1~-0.4 | 1500℃x2h 0.1~-0.4 | 1500℃x2h 0.1~-0.4 | 1550℃x2h -0.5~+0.5 | 1550℃x2h -0.5~+0.5 | 1550℃x2h -0.5~+0.5 |

Al2O3 Content , % | 48 | 55 | 65 | 75 | 80 | 85 | 82 |

Why us

Professional fire brick manufacturer. We have being specialized in producing refractory fireclay brick for more than 40 years so that we can guarantee a stable quality.

Guaranteed quality. Our production process conforms strictly to the requirements of ISO9000 quality management system. Quality inspection is carried out in every links of our production. SGS third party inspection is available.

Sound after sales service. We provide sound after sales service. We provide 24 hours’ consultation service. We are ready to answer your consultations at any time.

- Q: How do insulating fire bricks affect the overall energy consumption of a structure?

- A structure's overall energy consumption can be greatly reduced by the use of insulating fire bricks. These specialized bricks are designed to have low thermal conductivity, effectively preventing heat transfer. Installing them in the walls, floors, and roofs of a building significantly minimizes heat loss or gain through these surfaces. One major advantage of insulating fire bricks is their ability to improve a structure's thermal insulation. Heat naturally moves from hotter to cooler areas, causing buildings to experience heat loss in cold winters and heat gain in hot summers. By acting as a barrier, insulating fire bricks limit the transfer of heat through the building envelope. This insulation helps maintain a stable indoor temperature and reduces the need for excessive heating or cooling, resulting in lower energy consumption. Moreover, these bricks also enhance the overall energy efficiency of a structure by optimizing the performance of heating and cooling systems. Since they minimize heat transfer, the heating system can operate more efficiently without compensating for heat loss. Similarly, air conditioning systems can effectively cool the building with reduced heat gain. This efficient operation of HVAC systems leads to lower energy consumption and decreased energy demand for the structure. Additionally, insulating fire bricks contribute to the sustainability of a structure by reducing its carbon footprint. With reduced energy consumption, these bricks help lessen the environmental impact associated with the building. The decreased energy usage benefits not only the environment but also the occupants, as it results in lower utility bills and makes the structure more cost-effective in the long term. In conclusion, insulating fire bricks have a significant impact on a structure's overall energy consumption. Their excellent thermal insulation properties minimize heat loss or gain, improve the efficiency of heating and cooling systems, and contribute to the sustainability of the structure. Incorporating these bricks into the construction or renovation process effectively reduces energy consumption, resulting in a more energy-efficient and environmentally friendly building.

- Q: Can insulating fire bricks be used as a refractory material?

- Insulating fire bricks can indeed serve as a refractory material, given their specific design for enduring high temperatures and thermal shock. These bricks prove suitable for situations necessitating heat insulation and refractory properties. By virtue of their low thermal conductivity, they effectively diminish heat loss and conserve energy. Industries such as steel, glass, ceramics, and petrochemicals frequently employ insulating fire bricks as lining materials within furnaces, kilns, ovens, and other equipment operating at elevated temperatures. The combination of their capacity to withstand extreme temperatures and insulating characteristics renders them an outstanding option for refractory applications.

- Q: What are the new types of building brick materials?

- In addition to the original clay brick, other masonry materials seem to be called new materials. Sintered silt bricks, steam blocks, lightweight blocks, hollow clay bricks, etc..

- Q: Do insulating fire bricks have a high insulating capacity?

- Insulating fire bricks possess a remarkable capacity for insulation. Crafted with utmost precision, these bricks exhibit exceptional thermal insulation characteristics, rendering them exceptionally proficient in obstructing heat transfer. Their composition entails lightweight materials like ceramic fibers, known for their minimal thermal conductivity. Consequently, insulating fire bricks adeptly capture and maintain heat, effectively thwarting its escape and ensuring adequate insulation of the surrounding space. Owing to their superior insulating capacity, these bricks find extensive utilization in domains that prioritize heat retention and energy efficacy, including furnaces, kilns, and fireplaces.

- Q: Are insulating fire bricks resistant to abrasion or wear?

- Yes, insulating fire bricks are resistant to abrasion or wear. These bricks are made from high-quality refractory materials, such as alumina or silica, which have excellent resistance to abrasion. The manufacturing process involves high-temperature firing, which strengthens the bricks and enhances their durability. Insulating fire bricks are specifically designed to withstand the harsh conditions of high-temperature applications, such as furnaces, kilns, and fireplaces. They are highly resistant to thermal shock, chemical erosion, and mechanical wear. This makes them a reliable choice for insulating and protecting the inner walls of these structures, ensuring long-lasting performance and minimizing the need for frequent replacements.

- Q: Can insulating fire bricks be used in the construction of foundry furnaces?

- Certainly, foundry furnaces can utilize insulating fire bricks in their construction. These bricks, composed of lightweight materials such as ceramic fibers, vermiculite, or perlite, possess excellent insulating properties. With their ability to withstand high temperatures, they are deemed appropriate for foundry furnaces. To endure the intense heat generated during metal melting, foundry furnaces necessitate materials that are heat-resistant. Insulating fire bricks, with their exceptional heat transfer resistance, effectively minimize heat loss within the furnace. Consequently, they are an ideal choice for insulating the furnace's walls and floor, thereby enhancing energy efficiency and reducing fuel consumption. Furthermore, the lightweight nature of insulating fire bricks facilitates their handling and installation during furnace construction. Their lightweight composition also reduces the overall weight of the furnace structure, making it more portable and easier to relocate, if necessary. In summary, due to their outstanding insulating properties, heat resistance, and lightweight characteristics, insulating fire bricks are a suitable option for constructing foundry furnaces. By improving efficiency and performance while enduring the extreme temperatures required for metal melting, they prove to be highly advantageous.

- Q: Do insulating fire bricks have a low density?

- Insulating fire bricks possess a lower density in comparison to alternative brick types. Such bricks are engineered to embody a porous structure, thereby facilitating heat transfer reduction and insulation enhancement. The lightweight characteristic of these insulating fire bricks enables them to furnish efficient thermal insulation. Consequently, they prove apt for a multitude of applications wherein heat preservation and energy efficiency hold paramount significance, such as kilns, furnaces, and fireplaces.

- Q: Are insulating fire bricks resistant to phosphorus pentoxide?

- Yes, insulating fire bricks are resistant to phosphorus pentoxide.

- Q: Are there any safety precautions to consider when using insulating fire bricks?

- Yes, there are safety precautions to consider when using insulating fire bricks. Firstly, it is important to wear appropriate personal protective equipment, such as gloves and safety goggles, to protect against potential injuries. Additionally, due to the high temperatures involved, it is crucial to handle the bricks with care to avoid burns or related accidents. Adequate ventilation should be ensured to prevent the buildup of harmful gases and fumes. Lastly, it is essential to follow the manufacturer's instructions and guidelines for proper installation and usage to minimize any potential risks.

- Q: Can insulating fire bricks be used for insulation in hot blast stoves?

- Yes, insulating fire bricks can be used for insulation in hot blast stoves. These bricks are specifically designed to withstand high temperatures and provide excellent thermal insulation, making them suitable for use in hot blast stoves where temperatures can reach extremely high levels.

Send your message to us

Insulating Fire Brick:Low Conductivity Mullite Refractory Brick

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords