Insulating Fire Brick - Refractory GJM Mullite Insulation Brick B-7

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

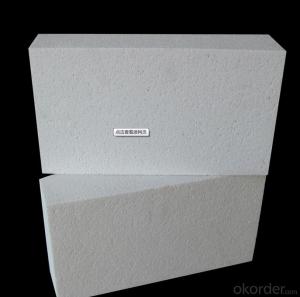

mullite insulation brick

1. Low thermal conductivity

2.High hot compressive strength

3.Perfect Energy saving

Refractory GJM Mullite Insulation Brick B-7

Light weight mullite insulation furnace bricks refractory for sale

Advantage

1. Low thermal conductivity

2.High hot compressive strength

3.Perfect Energy saving

Refractory GJM Mullite Insulation Brick B-7

Description:

Lightweight mullite kiln bricks refractory for sale are made from good quality and superpure raw materials, with strictly classified fillings according to their grades. These fillings can form a uniform pore structure after burnt during the process of manufacture. Each grade of products has unique design to meet different thermal, physical and chomical demands.

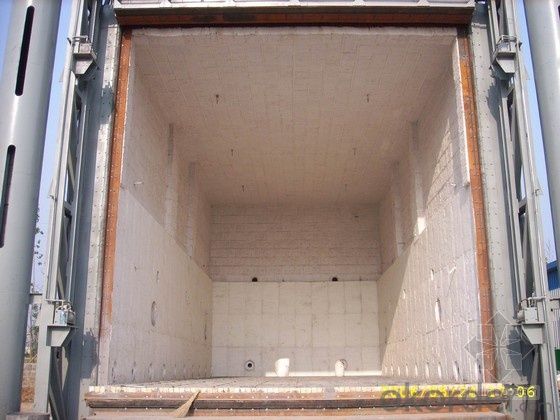

Application:Refractory GJM Mullite Insulation Brick B-7

Mullite insulation furnace bricks refractory material can be used in linings or heat-insulating materials of the industries, such as, ethylene pyrolysis furnaces, tubular furnaces, reforming furnaces of synthetic ammonia, gas generators and high-temperature shullte kilns, etcRefractory GJM Mullite Insulation Brick B-7

Mullite Insulation furnace refractory material can be used as working lining, where contact with flames directly. This kind of brick can save the kiln energy very much

Refractory GJM Mullite Insulation Brick B-7

- Q: Can insulating fire bricks be used as a refractory material?

- Yes, insulating fire bricks can be used as a refractory material. Insulating fire bricks are specifically designed to withstand high temperatures and thermal shock, making them suitable for applications that require heat insulation and refractory properties. They have low thermal conductivity, which helps to reduce heat loss and conserve energy. Insulating fire bricks are commonly used in various industries, including steel, glass, ceramics, and petrochemicals, where they are used as lining materials in furnaces, kilns, ovens, and other high-temperature equipment. Their ability to withstand extreme temperatures, coupled with their insulating properties, makes them an excellent choice for refractory applications.

- Q: Are insulating fire bricks suitable for insulation in refinery heaters?

- Yes, insulating fire bricks are suitable for insulation in refinery heaters. These bricks are specifically designed to withstand high temperatures and provide excellent insulation properties, making them ideal for use in refinery heaters where insulation is crucial to minimize heat loss and improve energy efficiency.

- Q: Can insulating fire bricks be used in foundries?

- Yes, insulating fire bricks can be used in foundries. They are commonly used as lining materials for various high-temperature applications, including foundries. Insulating fire bricks provide excellent thermal insulation, reducing heat loss and improving energy efficiency in the foundry process. Additionally, they have good resistance to thermal shock and can withstand the extreme temperatures and harsh conditions often found in foundry environments.

- Q: Can insulating fire bricks be used in the construction of pottery extruders?

- Yes, insulating fire bricks can be used in the construction of pottery extruders. These bricks are known for their high heat resistance, low thermal conductivity, and excellent insulating properties, making them suitable for applications where high temperatures are involved, such as pottery extrusion. They can help maintain a consistent temperature within the extruder, ensuring optimal working conditions for the clay and improving overall efficiency.

- Q: Can insulating fire bricks be used in the construction of foundry furnaces?

- Yes, insulating fire bricks can be used in the construction of foundry furnaces. Insulating fire bricks are made from lightweight materials that have high insulating properties, such as ceramic fibers, vermiculite, or perlite. These bricks are designed to withstand high temperatures, making them suitable for use in foundry furnaces. Foundry furnaces require materials that can withstand the extreme heat generated during the melting of metals. Insulating fire bricks have a high resistance to heat transfer, which helps to minimize heat loss in the furnace. This makes them an excellent choice for insulating the walls and floor of the furnace, as they can help to improve energy efficiency and reduce fuel consumption. Additionally, insulating fire bricks are lightweight, which makes them easier to handle and install in the construction of the furnace. Their lightweight nature also reduces the overall weight of the furnace structure, making it more portable and easier to move if needed. Overall, insulating fire bricks are a suitable choice for the construction of foundry furnaces due to their high insulating properties, resistance to heat, and lightweight nature. They can help improve the efficiency and performance of the furnace while withstanding the extreme temperatures required for metal melting.

- Q: Are insulating fire bricks resistant to molten metals?

- Yes, insulating fire bricks are generally resistant to molten metals. They are specifically designed to withstand high temperatures and provide insulation, making them suitable for applications involving molten metals.

- Q: Do insulating fire bricks have good mechanical strength?

- Insulating fire bricks generally have moderate mechanical strength compared to regular fire bricks. While their main purpose is to provide excellent thermal insulation, they are still able to withstand some amount of mechanical stress. However, it is important to note that their mechanical strength may not be as high as other types of fire bricks, which are specifically designed to withstand heavier loads and abrasion. Therefore, if the application requires both high insulation and superior mechanical strength, it might be necessary to consider using a combination of insulating fire bricks and regular fire bricks to achieve the desired outcome.

- Q: Do insulating fire bricks require any curing or drying time before use?

- Insulating fire bricks must undergo a curing or drying period prior to use. This is necessary because the bricks are manufactured using binders and additives that need to be cured or dried in order to ensure optimal performance and durability. Through the curing or drying process, these materials harden and solidify, thereby enhancing the insulation capabilities of the bricks. Neglecting to properly cure or dry the bricks before use can lead to decreased insulation efficiency and potential damage to the bricks when exposed to heat. To ensure the best results, it is advised to adhere to the manufacturer's instructions regarding the specific curing or drying time required for the insulating fire bricks.

- Q: Can insulating fire bricks be used in boilers for residential heating?

- Insulating fire bricks can indeed be utilized for residential heating boilers. These bricks are specifically engineered to endure elevated temperatures and offer superior thermal insulation properties. Their utilization in boiler and furnace construction is widespread due to their remarkable heat retention capabilities and ability to prevent heat dissipation. Consequently, the incorporation of these bricks aids in enhancing the energy efficiency of the boiler system by minimizing heat transfer to the surroundings, resulting in more effective heating and reduced energy consumption. Furthermore, the durability and resistance to thermal shock exhibited by insulating fire bricks make them ideal for withstanding the intense temperatures and rapid temperature fluctuations typically encountered in boilers. Consequently, their implementation in residential heating boilers serves to enhance both performance and energy efficiency.

- Q: Can insulating fire bricks be used for insulation in chemical plants?

- Yes, insulating fire bricks can be used for insulation in chemical plants. These bricks are made from lightweight materials with high insulating properties, such as ceramic fibers or refractory materials. They are designed to withstand high temperatures, making them suitable for use in environments with chemical processes that generate heat. Insulating fire bricks can be used in various applications within chemical plants, including lining for furnaces, reactors, kilns, and other equipment. Their excellent insulating properties help to reduce heat loss, conserve energy, and maintain optimal operating temperatures, ensuring the efficiency and safety of the chemical processes.

Send your message to us

Insulating Fire Brick - Refractory GJM Mullite Insulation Brick B-7

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords