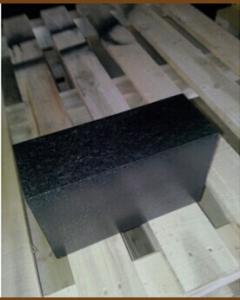

Refractory Brick/Refractory Magnesia-Pleonaste/Refracory Lining of Cement Plant

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

CNBM conforms strictly to the requirements of ISO 9000 quality control system during the production. MSDS is also available if you want. The thermal insulation fire clay brick meet with the requirements of ASTM & JIS standards. So pls stay cool with our quality.

Insulating Fire Brick Technical index

Product No. | IFB70 | IFB60 | IFB50 | IFB40 |

Al2O3 | 68%-72% | 58%-62% | 48%-52% | 38%-40% |

Refractoriness (°C ) | ≥1790 | ≥1790 | ≥1790 | ≥1790 |

Bulk density (g/cm3) | 2.50-2.60 | 2.35-2.45 | 2.20-2.30 | 2.10-2.20 |

Apparent porosity (%) | 22 | 19-22 | 17-20 | 17-20 |

Cold Crushing strength (kg) | 480-510 | 450-480 | 430-450 | 390-430 |

Application

Insulating Fire Brick are used for the lining of converter, alternating current arc furnace, direct Current arc furnace and the ladle slag line, etc.

Equipment

1 unit of Ceramic Abrasive (SG Abrasive) pilot production line

2 units of Compact grain Abrasive pilot production lines

1 unit of high-end coated abrasives (abrasive cloth) production line

Company Advantage

(1)Long Insulating Fire Brick manufacture history: 25 years manufacturer

(2)Advanced equipment

(3)Diversification of production standards: ISO ANSI FEPA JIS ASTM

(4)Flexible payment: T/T L/C D/P D/A

(5)Professional marketing team and after-sale service

(6)Free sample

FAQs

Q1 |

What’s the transport method? |

A1 | FCL delivery goods with wooden pallet or wooden case by sea; If LCL delivery, must with wooden case; Sometimes need open top, flat rack or bulk cargo. |

Q2 |

What’s the required payment term? |

A2 | Generally 30% TT as the prepayment, 70% TT before delivery. If need, 100% Irrevocable Letter of Credit or negotiation. |

Q3 |

Which country are our products exported to? |

A3 | Apart from entire Chinese market, the US, Russia, Japan, Korea, Australia and some Southeast Asian Nations. |

- Q: Can insulating fire bricks be used in waste incineration plants?

- Yes, insulating fire bricks can be used in waste incineration plants. Insulating fire bricks are designed to withstand high temperatures, making them suitable for use in the extremely hot environment of waste incineration plants. These bricks are made from lightweight materials that have excellent thermal insulation properties, which helps to reduce heat loss and improve energy efficiency in the incineration process. Additionally, insulating fire bricks have good resistance to chemical and thermal shock, which is important in waste incineration plants where various types of waste materials are burned. Overall, the use of insulating fire bricks in waste incineration plants can contribute to better insulation, higher energy efficiency, and improved performance of the incineration process.

- Q: Can insulating fire bricks be used in the construction of BBQ pits?

- Indeed, the utilization of insulating fire bricks is feasible for the construction of BBQ pits. These bricks are specifically engineered to endure extreme temperatures and possess exceptional heat resistance attributes, rendering them perfectly suited for BBQ pit applications. By incorporating these bricks, heat is effectively captured and evenly dispersed, leading to improved cooking efficiency and a more enjoyable BBQ experience. Moreover, the inclusion of insulating fire bricks aids in minimizing heat dissipation, guaranteeing that the BBQ pit retains and sustains heat for an extended duration. All in all, the integration of insulating fire bricks significantly enhances the overall performance and longevity of the BBQ pit.

- Q: Are insulating fire bricks resistant to slag attack?

- Insulating fire bricks have a general resistance to slag attack. They are made from lightweight and porous materials, like alumina, silica, and other refractory materials. These bricks are designed to provide excellent insulation and high-temperature resistance in various industrial applications, such as furnaces, kilns, and incinerators. When we talk about slag attack, we are referring to the corrosion or erosion caused by molten slag. This slag is a byproduct of certain industrial processes, such as metal smelting or coal combustion. It can be highly corrosive and damage refractory materials, including fire bricks. However, insulating fire bricks are specifically formulated to resist slag attack. They have a composition and structure that allows them to withstand the corrosive nature of molten slag. This helps prevent erosion and maintain their insulating properties over time. Furthermore, insulating fire bricks can have different levels of slag resistance, depending on their specific composition and manufacturing process. Some fire bricks may even have additives or coatings to enhance their resistance to slag attack. It's important to note that while insulating fire bricks offer good resistance to slag attack, the severity and duration of exposure to slag can impact their performance. In highly corrosive environments or prolonged exposure to molten slag, even the most resistant fire bricks may eventually experience some degradation. Overall, insulating fire bricks are a reliable choice for applications where resistance to slag attack is necessary. However, it's always recommended to consult with a refractory engineer or supplier to ensure the appropriate selection of fire bricks based on the specific conditions and requirements of the industrial process.

- Q: Are insulating fire bricks suitable for use in heat exchangers?

- Insulating fire bricks can be suitable for use in heat exchangers, depending on the specific requirements and conditions of the heat exchanger application. Insulating fire bricks have high thermal insulation properties, low thermal conductivity, and excellent resistance to high temperatures. These qualities make them effective in minimizing heat loss and conserving energy in heat exchanger systems. Furthermore, insulating fire bricks are lightweight and have good mechanical strength, which allows for easy installation and maintenance. They are also resistant to thermal shock and chemical corrosion, ensuring durability and longevity in harsh operating environments. However, it is important to note that insulating fire bricks may not be suitable for all heat exchanger applications. In cases where high thermal conductivity is required for efficient heat transfer, such as in some types of industrial heat exchangers, other materials with higher thermal conductivity should be considered. Ultimately, the suitability of insulating fire bricks for use in heat exchangers depends on factors such as the specific operating conditions, design requirements, and performance expectations of the heat exchanger system. It is recommended to consult with experts or engineers familiar with heat exchanger design and materials to determine the most appropriate choice for a particular application.

- Q: Can insulating fire bricks be used in the construction of hearths?

- Indeed, hearths can be constructed using insulating fire bricks. These bricks are specifically engineered to endure extreme temperatures, rendering them a superb selection for hearth construction. With their low thermal conductivity, they effectively retain heat and hinder the transmission of heat to nearby surroundings. Consequently, they are perfect for establishing a well-insulated and efficient hearth. Furthermore, their lightweight and manageable nature make them highly convenient for construction tasks. All in all, insulating fire bricks prove to be a dependable and pragmatic choice for the development of hearths.

- Q: What is mullite insulation brick?

- Mullite brick, according to different density can be divided into: lightweight mullite brick and heavy mullite brick;

- Q: Are insulating fire bricks suitable for use in boilers?

- Yes, insulating fire bricks are suitable for use in boilers. They have excellent thermal insulation properties, which help to minimize heat loss and increase energy efficiency in boilers. Additionally, their high temperature resistance ensures they can withstand the extreme heat generated within the boiler.

- Q: Can insulating fire bricks be used in the construction of thermal oxidizers?

- Yes, insulating fire bricks can be used in the construction of thermal oxidizers. These bricks are designed to withstand high temperatures and provide excellent insulation, making them suitable for applications such as thermal oxidizers, which require efficient heat transfer and containment of high temperatures.

- Q: Can insulating fire bricks be used in high-velocity gas flow applications?

- Yes, insulating fire bricks can be used in high-velocity gas flow applications. Insulating fire bricks are designed to have excellent thermal insulation properties, low thermal conductivity, and high resistance to temperature fluctuations. These characteristics make them suitable for various high-temperature applications, including high-velocity gas flow environments. When exposed to high-velocity gas flow, insulating fire bricks can maintain their structural integrity and insulation properties, providing effective thermal insulation and protection. They are often used in applications such as kilns, furnaces, boilers, and other industrial equipment where high-velocity gas flow is present. However, it is important to consider the specific requirements and characteristics of the gas flow in the application. Factors such as temperature, pressure, and chemical composition of the gas should be taken into account to ensure that the insulating fire bricks are compatible and can withstand the conditions. In summary, insulating fire bricks can be used in high-velocity gas flow applications due to their thermal insulation properties and resistance to temperature fluctuations. However, it is crucial to consider the specific requirements and characteristics of the gas flow to ensure proper compatibility and performance.

- Q: Can insulating fire bricks be used in outdoor applications?

- Insulating fire bricks serve a specific purpose in high-temperature settings and are commonly found indoors, like in kilns, furnaces, and ovens. Although they are not typically advised for outdoor use, there are certain situations where they can be cautiously employed. Comprised of lightweight refractory materials, insulating fire bricks offer superb insulation and heat resistance. Nevertheless, they lack the durability and weather resistance of other brick types, such as clay or concrete bricks, which are better suited for outdoor environments. When used outdoors, insulating fire bricks may face harsh weather conditions like rain, snow, extreme temperatures, and UV radiation. These elements can lead to deterioration over time, causing a loss of insulation properties. Additionally, these bricks are more prone to cracking and damage due to thermal expansion and contraction resulting from temperature fluctuations. If you must use insulating fire bricks outdoors, it is crucial to take extra precautions to shield them from the elements. This may involve applying weatherproof coatings or sealants to minimize water absorption and prevent damage caused by freezing and thawing cycles. Adequate drainage and ventilation are also essential to avoid moisture buildup, as excessive moisture can compromise the bricks' insulation properties. In general, while insulating fire bricks can be utilized in outdoor settings under specific conditions, it is advisable to opt for more suitable materials for long-lasting durability and optimal performance.

Send your message to us

Refractory Brick/Refractory Magnesia-Pleonaste/Refracory Lining of Cement Plant

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords