Insulating Fire Brick Mullita Ladrilo Refractario Refractarios Aislantes JM 29

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 5000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Mullita ladrillo refractario refractarios aislantes JM 23

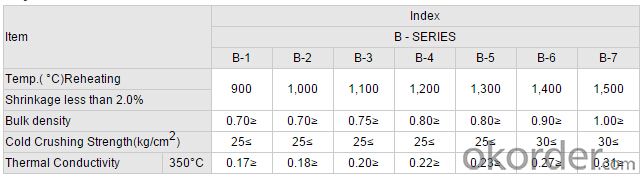

Aislamiento de calor de la serie okorder ladrillo

La serie okorder ladrillo es un eficaz aislamiento térmico, ahorro de energía, baja en carbono, la protección del medio ambiente avanzado, de acuerdo a la norma ASTM la fabricacion de productos.Okorder serie productos son mejores Li Ning y aislamiento en todo tipo de hornos industriales en el sector metalurgico, aluminio, petroquímica, energía eléctrica y materiales de cerámica de vidrio.Pueden ser utilizados como parte de la capa de aislamiento termico o non - Fusion.Los productos han sido ampliamente utilizados en el horno, logra resultados satisfactorios.

Aplicación de la preservación del calor de ladrillo

Industria metalurgica: Blast Furnace, hot alto horno, horno de calefaccion, etc.

Industria petroquímica: etileno horno horno de cracking, producción de hidrógeno, reformador primario, horno de calefaccion, etc.

Industria: horno de rodillos de cerámica, horno, etc.

Industria del vidrio: vidrio horno regenerador, etc.

Industria de carbono: carbono horno, etc.

Sector de la electrólisis de aluminio: aluminio reducción celular, etc.

Otras industrias: horno de tunel, Servicio de horno, etc.

Ventajas de ladrillo del aislamiento de calor

Baja conductividad térmica: mayor porosidad traerá buen aislamiento termico, ahorro de energía.

Alta resistencia al aplastamiento: alta resistencia al aplastamiento, la estabilidad de volumen.

Almacenamiento de calor: pequeños de almacenamiento de calor bajo para absorber más calor, ahorro de efecto es evidente.

Gao Chundu: hierro, metal alcalino de bajo contenido de impurezas.

El tamaño exacto: tamaño de ladrillo precision de procesamiento, forma especial de corte y molienda, acelerar el ladrillo.

Foto de ladrillo aislante

Problema común soluciones

1.¿Que productos tienes?

Disponemos de todo tipo de ladrillos refractarios, refractarios materiales de fundicion, mortero, cemento, productos de fibra cerámica, etc.

O usted puede hojear nuestros productos a elegir lo que usted necesita.

2.¿Cómo controlar la calidad del producto?

Con sistema de estricto control de calidad en la seleccion de materiales y el proceso de producción, tenemos la calidad de materiales refractarios y productos de fibra cerámica para satisfacer las necesidades de los clientes.

Desde la seleccion de materias primas, la calidad de nuestro control para empezar.El certificado de calidad de la materia prima es necesaria, cada lote de los productos serán probados en el uso de la línea.En el proceso de producción, el control de calidad por los trabajadores, y luego cada pieza de la clasificación, y mediante la supervisión de la calidad y la inspección.

3.¿Me puedes dar una breve introducción a la aplicación de su producto?

Mi empresa se dedica principalmente en refractarios en el acero, cemento, vidrio, cerámica, petroquímica, energía eléctrica y otras industrias.

4.¿Qué información necesitas si te necesito?

Con el fin de seleccionar los productos adecuados, que nos proporcionará la información, tales como los Estados Unidos, datos técnicos, cantidad de pedido, la aplicación del producto, etc.

Si usted tiene alguna pregunta, por favor pongase en contacto con nosotros.

- Q: Are insulating fire bricks suitable for use in coke ovens?

- Insulating fire bricks are not suitable for use in coke ovens. Coke ovens require bricks that can withstand extremely high temperatures and harsh chemical environments. Insulating fire bricks are designed to provide thermal insulation and are not able to withstand the heat and chemical exposure that occurs in coke ovens. Therefore, it is crucial to use refractory bricks specifically designed for coke ovens, which have high resistance to temperature, chemical attacks, and thermal shock. These refractory bricks are typically made from materials such as silica, alumina, and carbon, which can withstand the harsh conditions inside the coke ovens.

- Q: Are insulating fire bricks suitable for use in chimneys and fireplaces?

- Yes, insulating fire bricks are suitable for use in chimneys and fireplaces. They have excellent thermal insulation properties, which helps to retain heat and prevent the transfer of excessive heat to the surrounding structure. This makes them a safe and efficient choice for lining chimneys and fireplaces, as they can withstand high temperatures and reduce the risk of heat damage.

- Q: Can insulating fire bricks be used for insulation in power boiler walls?

- Yes, insulating fire bricks can be used for insulation in power boiler walls. Insulating fire bricks are designed to provide excellent thermal insulation, high temperature resistance, and low thermal conductivity. These properties make them suitable for use in power boiler walls, where insulation is crucial to reduce heat loss and improve energy efficiency.

- Q: Are insulating fire bricks suitable for insulation in refinery heaters?

- Yes, insulating fire bricks are suitable for insulation in refinery heaters. These bricks are specifically designed to withstand high temperatures and provide excellent insulation properties, making them ideal for use in refinery heaters where insulation is crucial to minimize heat loss and improve energy efficiency.

- Q: Can insulating fire bricks be used as a heat shield?

- Yes, insulating fire bricks can be used as a heat shield. Insulating fire bricks are designed to have excellent thermal insulation properties, which means that they can effectively block and reflect heat. They are commonly used in applications where heat needs to be contained or redirected, such as in fireplaces, kilns, furnaces, and industrial ovens. The insulating properties of these bricks allow them to reduce heat transfer, providing a barrier between the intense heat source and the surrounding environment. Additionally, they have high melting points and can withstand high temperatures, making them suitable for use as a heat shield. However, it is important to note that the effectiveness of insulating fire bricks as a heat shield may vary depending on the specific requirements and conditions of the application.

- Q: Are insulating fire bricks resistant to oil and gas?

- Insulating fire bricks typically offer resistance against oil and gas. These bricks are crafted from high temperature materials like alumina and silica, which grant exceptional thermal insulation qualities and can endure elevated temperatures. They are commonly employed in industries where exposure to heat occurs, such as furnaces, kilns, and fireplaces. Nevertheless, it is crucial to acknowledge that the resistance to oil and gas can vary depending on the precise composition and manufacturing process of the insulating fire bricks. Certain bricks may exhibit higher resistance to oil and gas compared to others. To guarantee the utmost resistance to oil and gas, it is recommended to utilize insulating fire bricks that are specifically engineered for such applications. These bricks are often known as oil and gas resistant fire bricks and are formulated with supplementary additives or coatings that enhance their resistance to these substances. In conclusion, although insulating fire bricks generally offer resistance to oil and gas, it is advisable to employ bricks that are specifically tailored for such applications to ensure optimal performance and longevity.

- Q: Do insulating fire bricks have any impact on indoor air quality?

- Insulating fire bricks, also known as refractory bricks, are primarily used in high-temperature applications such as fireplaces, kilns, and furnaces. These bricks are designed to withstand extreme heat and provide insulation, preventing the transfer of heat to surrounding areas. In terms of indoor air quality, insulating fire bricks do not have a direct impact. Since insulating fire bricks are made from materials such as clay, alumina, and silica, they are generally inert and do not release any harmful substances into the air when exposed to normal temperatures. However, it is important to note that during the manufacturing process, certain chemicals or additives may be used, which could potentially have an impact on air quality if not properly regulated or controlled. Additionally, the installation and maintenance of insulating fire bricks can indirectly affect indoor air quality. For example, if the bricks are not installed correctly or become damaged over time, they may develop cracks or gaps that could allow the escape of harmful gases or particulate matter. In such cases, it is crucial to promptly repair or replace damaged bricks to ensure the integrity of the insulation and prevent any negative impact on indoor air quality. Furthermore, the use of insulating fire bricks in fireplaces or wood-burning stoves can indirectly influence indoor air quality. When these devices are operated, they can release smoke, particulate matter, and potentially harmful gases into the air. It is essential to ensure proper ventilation and use high-quality flue systems to minimize the impact on indoor air quality when using such appliances. In summary, insulating fire bricks themselves do not have a direct impact on indoor air quality. However, it is important to consider factors such as the manufacturing process, installation, and maintenance to ensure that these bricks do not contribute to any degradation of the air we breathe.

- Q: Can insulating fire bricks be used in DIY projects?

- Certainly, DIY projects can make use of insulating fire bricks. With their lightweight and superb thermal insulation properties, these bricks prove suitable for a range of applications. They find common use in the construction of wood-fired ovens, fire pits, kilns, and even forge walls. Insulating fire bricks possess the ability to endure high temperatures and resist thermal shock, thus providing a dependable option for heat-resistant structures crafted by DIY enthusiasts. Furthermore, they offer ease of cutting and shaping, enabling customization to align with specific project requirements.

- Q: What are the bubble bricks?

- The requirements for production conditions are not high. Simple shed to plant products without open storage, warehouse, on the quality of workers is not high.

- Q: Can insulating fire bricks be used in ceramic fiber boards?

- Yes, insulating fire bricks can be used in ceramic fiber boards as they provide thermal insulation and enhance the overall insulation properties of the boards.

Send your message to us

Insulating Fire Brick Mullita Ladrilo Refractario Refractarios Aislantes JM 29

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 5000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords