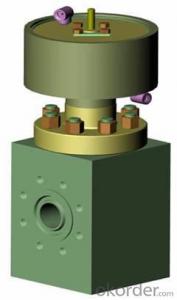

Hydraulic Rexroth Throttle Valve Yuken Pressure Hydraulic Relief Valve

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 unit

- Supply Capability:

- 1000 unit/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Quick Details

| Standard or Nonstandard: | Standard | Structure: | Check | Pressure: | High Pressure |

| Power: | Hydraulic | Material: | Casting | Temperature of Media: | Medium Temperature |

| Media: | Oil | Place of Origin: | China (Mainland) | Model Number: | MS |

| Brand Name: | OKORDER | Color: | Black or customer made | Quality: | Great |

| OEM: | Yes | Valve type: | Check valve |

Packaging & Delivery

| Packaging Detail: | 1 Plastic 2 Small carton 3 Large Carton 4 Wooden case |

| Delivery Detail: | according to order |

Specifications

Hydraulic Rexroth Throttle Valve Yuken Pressure Hydraulic Relief Valve

1 High quality

2 Good service

3 Rexroth type Vickers

- Q: I am replacing my vanity sink with a Pedestal sink. I turned the shut off vales to the off position tight.I disconnected the cold water and drained the remaining water and everything was fine. I disconnected the hot and drained the water from the connecting tube but water still came out of the shut off valve at a decent pace.I placed my finger over the valve and i felt pressure build up...like when you stick your finger over a bottle of soda.I tightened the bolt on the valve and even the screw to the handle to no resolve.any ideas on how to make it stop while i connect the Pedestal sink?also, i am as novice as it gets.thanks in advance

- The valves packing (seat) is probably worn and it wont seal. Either repair of the valve is in order, rebuild. You need to shut the water main off. Most houses have a master shut off valve that kill all the water to the house. If no such valve exists, then you would need to go out to the water meter and shut the water off at the meter to kill the flow to the house. Then install and make your repairs and install your new sink. The valve repair must be done when the water is off to the house. You cant fix it with the water on.

- Q: What is the specific use of an angle valve

- I okorder /... I hope that I adequately answered your question. Wingman

- Q: Ok, I recent rebuilt a set of vortec heads, but the valves I got are a bit longer than stock, I believe .1 competition products pn I2552P. I also installed howards cam 98214 springs with 10° locks and retainers, the locks are +.035. I was just wondering if I would have enough spring pressure.

- You need to measure your installed height. No guessing here at all. Measure to be sure. If you don't have a valve spring micometer, you can use a std dail caliper's outside jaws. Remove spring, put retainer on, put 2 locks in, and pull up on retainer till it seats in lock groove. Now measure from spring seat on heads to bottom of retainer.. If you have to then you can measure to top of retainer and then measure thickness of retainer and take that off of your total. You have to know the installed height to figure spring pressure change. The 98214 springs has a rate of 411.. That 411 # per 1 inch and rated installed height is 1.700 So you take the amount of change from the 1.700 and X it by the rate of 411 and that's your total pressure change.. Then take or add that to your rated pressure (which is 115 #) and that gives you your new spring pressure So lets just say installed height is now 1.750 So .050 x 411 = 20.55 #, 115 - 20.55 = 94.45 # total seat pressure Now you need to list the cam your running, diff lift needs diff amount of spring pressure ***EDIT*** Thats a .465 lift cam. If your not winging RPMs past 5,000 then you can get away with a 80 # seat pressure spring, 6K rpm you would need about 5-8 # more seat pressure

- Q: 2003 Ford Focus SE2.0L SPI EngineAutomatic Transmission 145KPerfectly maintained since new!One of the pistons had snapped, yes the actual piston, it didn't mess up the walls, but I am hearing a LOT about these dropping valve seatsI intended to do an entire rebuild with a kit, but did it break BECAUSE of a droppedvalve seat?I don't know because I don't know what that isHelp is appreciated

- I don't know if cars really have replaceable valve seats or seats that can come loose (maybe they do with aluminum heads). But if a valve contacts a piston for whatever reason the valve and piston can sort of disappear (ie, break up). How many miles are on the car, and if it has a timing belt, did you ever replace the timing belt at the recommended miles (not normally an issue for engines with timing chain). Many engines are interference engines which means that if the timing belt breaks and pistons keep moving, a piston can hit a valve. Although, we had a regular V8 engine do that (valve and piston disappear) with a car from the late 1960's (not sure of actual cause, we replaced it with a used engine).

- Q: What is the easiest and best way to fix a leaking shut-off valve on a toilet?

- Take out the old one. it is easy it just slides up the over flow tube go to a hardware store and get a replacement ball valve (Ballcock) they are just a couple bucks.slide the new one on! Take the old one when you go to get the new one.

- Q: i recently adjusted my valves on my 01 civic with a 1.7 sohc vtec motor and i did it to the specs under the hood and i didnt have them too tight or too loose on the feeler gauge and they are pretty loud are these motors just that noisy? has anyone else adjusted them to something different that works better?

- The dude above is physically powerful, yet incorrect on the fee. you may get an entire swifter equipment for about 1k, a reliable setup will fee a million.5k to 2k with injectors, gasoline pump, a turbine, and an intercooler. 01 are heavy and not super to do mods to, additionally d16 sucks inventory, so which you're able to additionally could desire to yet internals with expenses 900 for the aspects (pistons and rods). entire could be 2k to 3k for an extremely super setup for 250 to 300hp

- Q: what is a silicone purge valve.

- There are a number of things that will Toss out and ERG code on Fords (another reason I will never own another ford as long as I live) Double check all joints around the EGR valve and the tubes that connect too it. You may have a pin hole in one of the tubes or a loose coupler. If everything checks out there. Verify the vacuum line going to the EGR is not cracked, rotted, broken, or clogged. If it is replace the line. Next you need to check and make sure the valve is opening at the correct time. If the EGR is slow to open, becomes stuck half way or is opening to quickly, these will all toss out EGR codes. Then there is the possibility that the tubes for the EGR, or the EGR it's self may be clogged as well. In which case you need to remove them and clean them out. Hope this helps in your trouble shooting. Good luck.

- Q: recently changed head gasket. could valves tap from the push rods being mixed up? they all seemed to be the same size and i know the other side was exactly the same when put back together but this side is mixed up. could this make the valves go crazy? and i need to replace my water pump because its getting very hot and no coolant moving. and everything is smokin up, took off oil cap and it was steaming. would that have anything to do with making the valves tap?

- Ok The push rods are fine. There is no order they go in. The valves are taping due to poor lubrication, also did you do a valve job before u put the gaskets on? Also Use STP oil treatment after replacing the gaskets its a thicker oil that lubes better. The water pump wont be ur only issue. it sound like there is some restriction in the cooling system, Firs check the upper radiator hose it should be hot not cold, check the reservoir its shouldn't be over flowing and make sure the V-belt is in good condition make sure there are no cracks in the belt. make sure The thermostat is installed correctly and Check the radiator it self if the radiator is back-up i recommend a new one if u cant affored it remove radiator and have i boiled out clean. Oh just for safe measure get a block test done just so u will know there are no cracks in the block

- Q: I've just been told that I need to replace the valve cover gasket on my 97 Volvo 850.....to the tune of $650.00 .....ouch.....is it that difficult to fix?......can you use the red gasket sealant? is there a difference between the head gasket and the valve cover gasket.......yeah I know there probably is.......but when I look on line all i can find is head gaskets......no valve cover gaskets........which scares me into thinking they are the same thing.....i'm hopeing i'm wrong......if its the valve cover gasket it looks like it would be right on top of the engine and fairly accessable.......or am I wrong......sure would like to save the $650 if it is something i can do myself!!!!

- Valve Cover Gasket is a tuff thing to fix alone. I would say, take it to the shop and pay the $650.00- look at it like this, at least you will have a garentee if anything goes wrong you take that bad boy back and have them hook it up the right way! Best of Luck!

- Q: I have just been diagnosed with a Mitral Valve disorder. The Doc's notes say Trace Center Regurgitation. Also Trivial Tricuspid Regurgitation. In simple terms, what do these things mean, what causes it, and how do you treat it?

- If there is regurgitation but it's minimal, you likely have little to worry about. Mitral Valve disorder is commonly known as a heart murmur. Many people have them. It's only when there's regurgitation involved that it becomes more complicated. Since yours is trace and trivial it definitely requires investigation. At some point they may want to do a repair of the valve or a replacment but that depends on the degree of regurgitation. Regurgitation simply means that the valve does not close properly when the heart pumps out blood. It is the abnormal leaking of blood from the left ventricle, through the mitral valve, and into the left atrium, when the left ventricle contracts, i.e. there is regurgitation of blood back into the left atrium. Treatment will depend on the severity of the regurgitation so it's something you'll need to discuss with your doctor/specialist.

Send your message to us

Hydraulic Rexroth Throttle Valve Yuken Pressure Hydraulic Relief Valve

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 unit

- Supply Capability:

- 1000 unit/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords