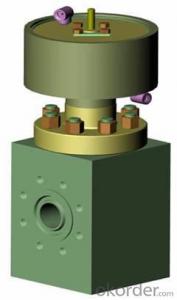

hydraulic directional solenoid valve BOSCH REXROTH types of control valves

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 PCS

- Supply Capability:

- 1000 PCS/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

hydraulic directional solenoid valve BOSCH REXROTH types of control valves

YUKEN ,REXROTH VICKER KINDS

12V 24V DC , 230V 110V

hydraulic flow control valve BOSCH REXROTH type 4WE6D62/EG12N9K4

Rexroth 4WE6 of 4WE6A,4WE6B,4WE6C,4WE6D,4WE6E,4WE6F,4WE6J,4WE6H,4WE6G,4WE6L,

4WE6M,4WE6P,4WE6Q,4WE6R,4WE6T,4WE6U,4WE6V,4WE6W,4WE6Y hydraulic solenoid valve

1. Nominal size 6 (cetop 3)

2. Completely interchangeable with Vickers and Yuken

3. Very competitive price

4. 1 year of warranty

5. Widely used for various hydraulic systems

6. Max. operating pressure up to 350 bar(5076psi)

7. Max. flow 80L/min( 21 US gpm)=60 L/min (15.8 US gpm)-AC

8. Direct operated directional spool valve with solenoid actuation in high perfomance version

9. Porting pattern to DIN 24340 form A (without locating bore)

10. Porting pattern to ISO 4401-03-02-0-05 and NFPA T3.5.1 R2 D03 (with locating bore)

11. Wet-pin DC or AC voltage solenoids with demountable coil

12. Solenoid coil can be rotated 900

13. The coil can be changed without open the the pressure-tight chamber

14. Electrical connection as individual or central connection

15. Manual override, optional.

hydraulic solenoid valve Vickers DG4V series

model:01 02 03

maximum pressure(Mpa) 31.5

maximum flow(l/min) 14 35 63

Electrical operated directional control valve uses solenoid to pull the spool and change the direction of the hydraulic oil.

Electrical operated directional control valve can directly control the flow on-off and change. It also can be used as the pilot-operated valve,which coulf operate other valves.

- Q: Where is the filling portion of the valve?

- The middle of the screw down valve handwheel saw packing gland generally about two screws fixed or fixed on the pressure cap down is the appearance of the packing is not seen inside if leakage occurs usually filler filler fastening screws, general pressure valves are graphite filler

- Q: So how does the valve turn on?

- The handle of the valve is opened along the pipe and perpendicular to the pipe

- Q: What is the difference between the valve before the pump and the valve after the pump?

- The effect is the same, but the pressure they bear is the opposite. The pump is subjected to negative pressure.

- Q: Which brand of electric valve is good?

- The electric actuator imports now commonly used with Omar, Rotok, SIEMENS, you should still work to decide which Denso, such as regulating type? Switch mode? Intelligent? Regular type? There are valves can choose some well-known brands

- Q: How do you calculate the valve wall thickness, pressure, and other valve design calculations in a spreadsheet?

- For you to introduce the spreadsheet calculation, application basis, you according to this principle for valve correlation calculation:When A1 and B1 cells are used as parameters, the amount of computation is calculated by C1. If the formula is X+Y=? In the A1 cell, fill in the X; fill the Y in the B1 cell; fill in the C1 cell with "=A1+B1"; enter the carriage, and then calculate the corresponding value in the C1 cell. For example: fill in 5 in the A1 cell; fill in 8 in the B1 cell; enter the carriage, and then appear in the C1 cell 13. Other calculations are the same, you will calculate the valve formula, such as the above fill in, given the corresponding parameters, the same can be calculated.

- Q: Air compressor out of the gas with what kind of valve control okay, globe valve or other?

- What's the use of your air compressor? Is it manual or automatic? By the way, I think it's ok if the demand is not very strictWhat we used on board was the cut-off.

- Q: Symbols for all types of valves

- In addition to the throttle valve (L) valve (H) valve (U) valve (Y) of the four types of valves, the other is according to the first letter of the easy to remember the four valve but also second word the first letter and the other valve is repeated with the first letter of a very good record I was just valve knowledge I hope to help you!

- Q: What is a heavy body valve?

- You should be asking what a heavy-duty valve is.This is only in the ordinary gate valve and cut-off valve on the distinction. Nowadays, ordinary gate valves and cut-off valves are divided into heavy-duty ones. Medium and light three kinds ~!

- Q: Valve pressure grade division

- Valves are classified by pressure:Vacuum valve - valve with operating pressure below standard atmospheric pressure.Low pressure valve - nominal pressure PN is less than 1.6MPa valve.Medium pressure valve - nominal pressure PN 2.5~6.4MPa valve.High pressure valve - nominal pressure PN10.0~80.0MPa valve.Ultra high pressure valve - nominal pressure PN greater than 100MPa valve.

- Q: How to open the gas valve with drawings

- First of all, you have to determine the direction of the valve opening, usually homeopathy, it is off, the reverse is open. First: to determine the opening of the valve, are generally ball valve, screw 90 degrees on it. Second. At the top of your house, there is a button that can be pulled out.

Send your message to us

hydraulic directional solenoid valve BOSCH REXROTH types of control valves

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 PCS

- Supply Capability:

- 1000 PCS/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords