High Pressure Valve Positioner Oxygen Pressure Reducing Valve KZ03-3

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Manual Wafer Butterfly Valve Description:

A butterfly valve is a valve which can be used for isolating or regulating flow. The closing mechanism takes the form of a disk. Operation is similar to that of a ball valve, which allows for quick shut off. Butterfly valves are generally favored because they are lower in cost to other valve designs as well as being lighter in weight, meaning less support is required. The disc is positioned in the center of the pipe, passing through the disc is a rod connected to an actuator on the outside of the valve. Rotating the actuator turns the disc either parallel or perpendicular to the flow. Unlike a ball valve, the disc is always present within the flow, therefore a pressure drop is always induced in the flow, regardless of valve position.

2.Main Features of the Manual Wafer Butterfly Valve

a)Cast hole. Flange connection meet ANSI 125/150# DIN PN10/16 BS4504 PN10/16 in the meanwhile.

b)Soft seat. Replaceable. Increase of service life.

c)Double half shaft without pin.

d) Square and short neck. Easy to stick scutcheon and cost saving.

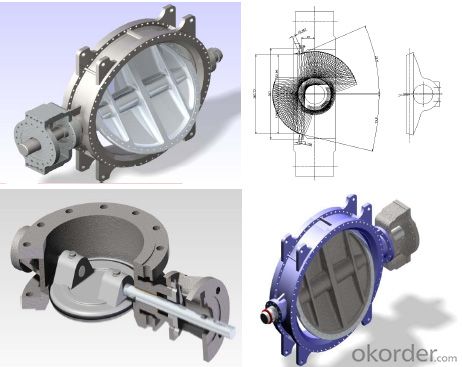

3. Manual Wafer Butterfly Valve Images:

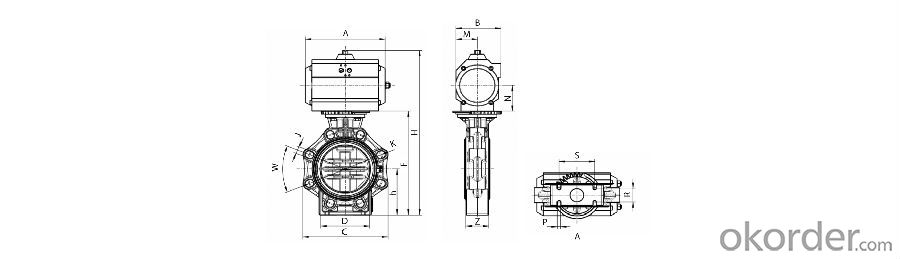

4.Manual Wafer Butterfly Valve Specification:

5.FAQ

1. What is manual wafer butterfly valve?

A: Wafer style is the more common of the two and is less expensive than the lug style. The wafer style butterfly valve is just about the standard. It ís so common that no one even bothers to use the word "wafer" when ordering a butterfly valve. It is taken for granted that if a butterfly valve is ordered, a wafer style will be received.

2. How about the Installation of the Wafer Style Butterfly Valve?

A: Butterfly valves are installed by inserting the valve between two flanges using bolts or studs and nuts to hold it all together. This type of installation, of course, makes it impossible to disconnect just one side of the piping system from the valve. That benefit is received using the lug style valve.

3. What is the working principle of manual wafer butterfly valve?

A: A butterfly valve is from a family of valves called quarter-turn valves. In operation, the valve is fully open or closed when the disc is rotated a quarter turn. The "butterfly" is a metal disc mounted on a rod. When the valve is closed, the disc is turned so that it completely blocks off the passageway. When the valve is fully open, the disc is rotated a quarter turn so that it allows an almost unrestricted passage of the fluid. The valve may also be opened incrementally to throttle flow.

- Q: What does LBC mean in a valve?

- LB and 800 are together. 800LB means 800 pounds of stress, and P should be PRESSURE.

- Q: Where is the Shanghai valve? What brand is good?

- To tell the truth, I think the Shanghai Yang Yi valve is good, in product quality, as well as product packaging are very good, especially after sale service, are free of charge

- Q: What kind of industry does valve belong to?

- Valve is the valve, regardless of other sectors

- Q: the use of natural connections, is strictly prohibited counterparts. What do you mean by "strong opposition"?

- From the literal explanation, the strong counterpart connection is different from the normal connection. Valves are naturally connected to pipes or equipment, including threaded connections, flanged connections, clamp connections, welding, butterfly valves, clamp connections, etc..Strong mouth connection, similar to the butterfly valve on the clip connection, just outside of clamping method used in other valves (not seen on the clip connection with other valves), so this will depend on external interface of the valve (wafer type butterfly valve, said strong counterparts except).

- Q: What does the whole copper valve mean?

- The whole valve is made of copper material. In addition to the ceramic core.

- Q: What are the advantages and disadvantages of this method? Are there any other ways to adjust the flow rate?

- With the advantages of the pump outlet valve adjustment, 1, you can control the pump outlet pressure, 2, you can control the motor current is not more than the process conditions, 3, control motor power, to ensure the normal operation of the pump.

- Q: What are the production equipment in valve shop?

- CNC machining center, double control vertical lathe, CNC lathe, CNC machine tools, heavy vertical double column lathe, spherical lathe horizontal boring machine, surface grinder, cylindrical grinder, lathe, milling machine, hydraulic head full bed, gate valve grinding machine, grinding machine, lathe, radial drilling machine,Powder plasma arc welding machine, thyristor rectifier, DC DC arc welding machine, welding machine, drying machine, trolley type resistance furnace, hook type shot blasting machine, medium pressure compressor, crane, pneumatic label printer, printer, compressed air sprayer spraying water line, air pressure box type resistance furnace. Forklift lifting platformLow temperature test equipment, metal and low temperature impact test machine, quantitative spectrometer imported carbon sulfide analyzer, microcomputer analyzer, spectrum analyzer, X-ray flaw detector X-, permeability detector, magnetic particle detector, ultrasonic thickness meter, digital ultrasonic flaw detector, metallographic microscope, hardness tester, precision analysis balance (hydraulic material testing machine), hydraulic valve testing machine hydraulic valve testing machine, submerged valve testing machine, steam trap test machine, valve testing machine, pressure testing machine temperature test machine

- Q: What are mine valves?

- In fact, much, no matter what the industry, with many types of valves. You want to see what works on the use of what media, in the choice of what type of valve is more appropriate.

- Q: What is the BV valve?

- It should be the meaning of BREATH VALVE, breather valve

- Q: someone else's home has valves, but also checked nothing, in addition to telephone repair, there are other ways? emergency

- That's a lie. Other people's homes do not necessarily have water.You need to keep on pressing the property.

Send your message to us

High Pressure Valve Positioner Oxygen Pressure Reducing Valve KZ03-3

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords