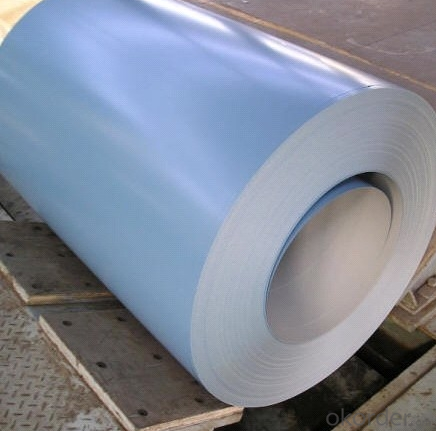

Prime PrepaintedHot-Dip and Galvanized Steel Coil CNBM

- Ref Price:

-

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 3000 m.t./month

Add to My Favorites

Follow us:

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Quick Details

| Standard: | AISI, ASTM, GB, JIS | Grade: | Q195/235/345,ASTM A36,SS400,SPHC | Thickness: | 1.5-25mm |

| Technique: | Hot Rolled | Application: | Container Plate | Special Use: | High-strength Steel Plate |

| Width: | 300-1500mm | Length: | coil | Surface Treatment: | black/bright/galvanized,etc |

| Authentication: | ISO9001-2008,SGS.BV,etc |

|

|

|

|

Packaging & Delivery

| Packaging Details: | tandard seaworthy export package or as customers required |

| Delivery Detail: | within 25 days after confirming the order |

Sepcification and Feature

Item | hot rolled pickled and oiled steel coil tianjin specialized manufacturing |

Brand Name | TJXH |

Business Type | A- level agency |

| Minerals & metallurgy |

Thickness | 1.8-20mm |

Width | 914-2000mm |

Coil weight | about 25 tons |

Material Grade | A36,Q195,Q235,SS400,SPHC,ST37/52 |

Technique | hot rolled |

Standard | AISI,ASTM,DIN,GB,JIS |

Test | With Hydraulic Testing, Eddy Current , Infrared Test |

Application | Construction,mechine,container manufacture, shipping building, bridge and other field |

Surface | 1) Bared 2) Black Painted (varnish coating) 3) Galvanized 4) Oiled 5) PE,3PE, FBE, corrosion resistant coating, Anti corrosion coating. chromated and oiled, chromated and non-oiled |

Package | in bundles, covered with waterproof-paper,strapped by strips. Or as customer’s requirement |

Sample | Common products, we can provide freely, for special production,we can depends on negotiation. |

MOQ | 20 tons |

Payment | 100% L/C at sight, 30% T/T in advance, and the balance against the copy of B/L or negotiation |

Delivery time | Within 10-25 days, according to quantity, asap save customer’s time |

Certificate | ISO |

What is the application of Steel Coil?

There are two sides,one is out side: Workshop, agricultural warehouse, residential precast unit, corrugated roof, roller shutter door, rainwater drainage pipe, retailer booth;the other is inside: Door, doorcase, light steel roof structure, folding screen, elevator, stairway, vent gutter.

- Q: How are steel coils used in the manufacturing of structural components?

- Steel coils are used in the manufacturing of structural components as they are typically used to form and shape various structural elements such as beams, columns, and trusses. These coils are unwound, flattened, and then processed through a series of machinery to be cut, shaped, and welded into the desired structural component. The steel coils provide a reliable and strong material base for the manufacturing process, ensuring the durability and stability of the final structural components.

- Q: My boyfriend is a loyal follower of this guy called Dr. Steel.

- Dr. Steel is an extremely complex phenomenon, a bit of a metaphorical nesting doll. On the surface, Dr. Steel can appear to some as simply a method actor musician with an over-the-top gimmick. Just underneath that facade lies an enigma; he makes some people wonder if he's really serious, just trying to entertain, or completely barking mad. But underneath the second facade, Dr. Steel is really acclaimed comic-book writer and chaos magickian, Grant Morrison. Make no mistake, he really thinks he is Dr. Steel. He has taken method acting and ceremonial magick to the highest levels, and fully intends to take over (or make over) the world. What's more, in the three short years since handing over his comic-book authorship to a ghost writer, he has amassed tens of thousands of followers worldwide. I've done several polls among Dr. Steel fans, and the results show that for every one person who has officially signed up, there are ten more loyal followers who have not.

- Q: I bought stainless steel appliances a year ago. I have two kids who like to put their hands all over the fridge and they always leave dirty marks all over it. I bought stainless steel cleaner but it doesn't do a good enough job. Anyone know any other cleaning remedies?

- I have a stainless steel cooker which is a nightmare. I've also tried everything but find the only thing that works for me is to wipe over with a damp cloth then immediately dry it with a dry cloth.

- Q: How are steel coils heat treated?

- Annealing is the method used to heat treat steel coils, resulting in improved mechanical properties and overall performance. To achieve this, the coils are heated to a specific temperature and slowly cooled down. This process relieves internal stresses within the steel and enhances its performance.

To begin the heating process, the steel coils are raised to a critical temperature, typically between 800°C and 900°C, depending on the desired outcome. They are then maintained at this temperature for a specific period of time, allowing for the transformation of the steel's microstructure.

Once the desired time has passed, the heated coils are carefully cooled down in a controlled manner. This gradual cooling process is crucial as it allows for a uniform and refined microstructure. It also helps prevent the formation of internal stresses that could weaken the steel.

The annealing process can be conducted in various atmospheres, such as air, nitrogen, or hydrogen. The choice of atmosphere depends on the specific requirements and properties desired for the steel coils. For example, annealing in a protective atmosphere like nitrogen or hydrogen can prevent oxidation or decarburization of the steel surface.

In conclusion, annealing is a crucial step in heat treating steel coils, resulting in improved mechanical properties, enhanced formability, and the desired characteristics for industrial applications.

- Q: It seems that steel would be stonger and more stable than wood, fire resistant, and better for the environment, so why are most homes wood-framed rather than steel-framed?

- Because it's always been done that way. Never underestimate inertia when asking why new materials/techniques are not adopted. Besides, the cost does not give steel a clear advantage. You can drive a nail anywhere into a stud. With steel, you have to drill your holes precisely.

- Q: Which movie is better and why?I say Man of Steel!

- Captain America: The First Avenger -- Mostly because it was a rousing, entertaining, old-school adventure film, plus it was true to the character of Steve Rogers/Captain America. Man of Steel, IMO, had a poor script, tinkered way too much with one of the great superhero origin stories and was not at all true to the character. Historically Superman has always been a symbol of heroism, proud, strong, beaming. But what we got in that movie was an utterly cheerless, dour automaton devoid of any kind of charisma or presence. I don't know who that boring, depressed dude who looked like Superman was in that movie, but he most certainly wasn't Superman.

- Q: How are steel coils used in the manufacturing of construction reinforcement bars?

- Steel coils are used in the manufacturing of construction reinforcement bars by being processed and shaped into the desired size and shape. The coils are first uncoiled and straightened, then cut into shorter lengths. These shorter lengths are then bent and twisted to create the necessary patterns and shapes, which provide enhanced strength and durability to the reinforcement bars.

- Q: What are the common coil edge options?

- The common coil edge options include open coil, continuous coil, offset coil, and pocket coil.

- Q: nylon sounds alot better but i want to keep the acoustic i have now. Is it proper to put nylon on an acoustic guitar meant for steel strings?

- Yes you can! The neck of the guitar will be fine if the tension is less (which it is for nylon strings). Knot the nylon strings about 3 times at the end then push through the bridge hole and push the pin down. The guitar will need tuning more regularly but the sound is great especially with a fibreglass bowlback (Martin Smith ?50 from E Bay). Through an amp it is awsome. A cheap fix. PS Don't wind around the winding post too many times as the extra tuning will stretch the strings.

- Q: Is a steel plate the same as a steel coil?

- You must have an open book and a flat plate, and it is a little bit harder to cut the parts than the plate.