Prepainted GI steel Coil/ PPGI / PPGL/ Color Coated Galvanized Steel Sheet in Coi/PPGI/SGCC/SGLCC

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Prepainted GI steel Coil/ PPGI / PPGL /Color Coated Galvanized Steel Sheet in Coil

1. Application of Prepainted GI steel Coil/ PPGI / PPGL/ Color Coated Galvanized Steel Sheet in Coil:

Construction, the manufacturing of cars, ships,containers and household electric appliances, other industries usage

they are mainly used in construction, light industry, automobile, agriculture, animal husbandry, fishery and commerce, etc industries.

.Manufacture anticorrosion, industrial and civil architecture roof boarding, roof grille.

.Make home appliance’s case, civil chimney, kitchen utensils, etc

.Corrosion resistant parts of cars

.Food storage, meat and aquatic products’ freezing and processing equipment etc;

.The equipments to store and transport materials, and packing implements.

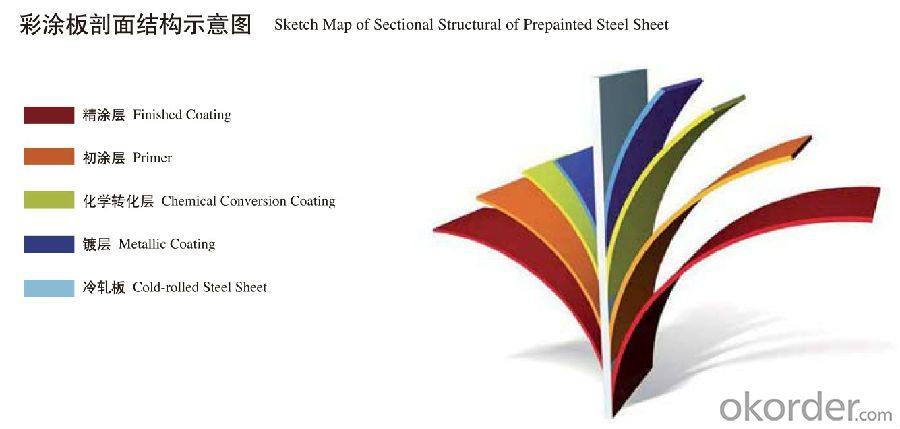

2.Features of Prepainted GI steel Coil/ PPGI / PPGL Color Coated Galvanized Steel Sheet in Coil:

* uses hot dip galvanized steel sheet as the base material

* zinc layer protection, dope on the zinc layer can cover and protect the

steel base from corrosion

* color coated sheet is light, beautiful and has good anti-erosion performancevanized steel coil

* As a rich experience manufacturer, we provide quality product, competitive price and reliable after-sales service.

3.Surface Finish of Prepainted GI steel Coil/ PPGI / PPGL/ Color Coated Galvanized Steel Sheet in Coil:

Surface finish | Pattern | Application |

Regular spangle | Standard spangles with flower pattern | General uses |

Small spanlge | Small spangles than regular | General painting applications |

Zero spangle | Extremely minimized spangles | Special painting applications |

4. Prepainted GI steel Coil/ PPGI / PPGL /Color Coated Galvanized Steel Sheet in Coil image:

APPLICATION:

PROUDUCTION LINE:

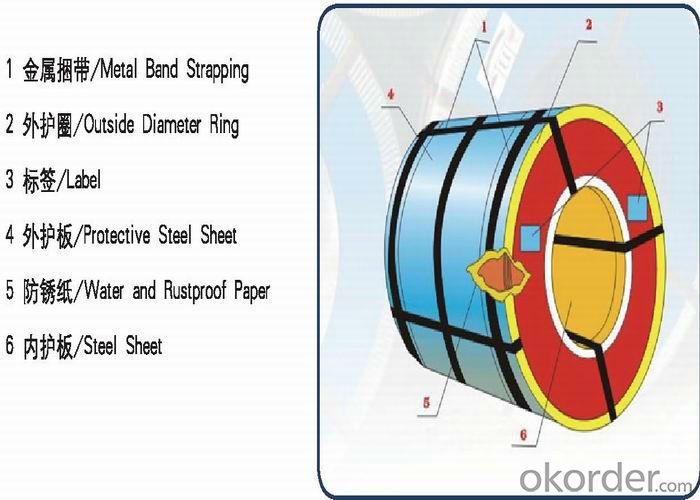

PACKING:

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your Warranty?

Warranty: 1-Year for the whole light. Warranty is based on correct storage, installation, using and maintenanc

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible.

- Q: I'm trying to bend stainless steel spoons, forks knives etc. for an art project. Will heating them help bend them into certain shapes or will heat only strengthen it? What is the best way to bend stainless steel?

- We are regular buyers of such bends.

- Q: i wanna buy a sharp carbon steel sword the swords i want are a 200 layer carbon steel katana or a hand forged high carbon steel katanna or a hand sharpened sword which one would be sharper/stronger

- Carbon steel is a generic term. There are many different grades of carbon steel consisting of several different components of various amounts, and there are different types of treatment the steel can go through that changes it's quality. Carbon steel swords are a step up from the crappy stainless steel swords, and other alloys. Sword quality completely depends on the smith. 200 layers doesn't mean there won't be any imperfections. Sword makers make mistakes, especially the lesser experienced ones. Look into the maker(s) of the sword you're looking to buy. Find information on them before deciding. Carbon steel is the steel to have, but that doesn't exclude good or bad quality. Sharpness will depend on the the steel and the smith.

- Q: If rail ties were melted, would they be like any other type of steel?

- Steel okorder ... If care is not taken in the method used to melt the steel that alloy will change because the carbon will burn in the process. Also part of a steels rating is a result of heat treatments used. When melted it will loose those properties. By the way rail road ties are either wood or concrete- not steel.

- Q: How are steel coils used in the manufacturing of electrical wiring?

- Steel coils are not typically used directly in the manufacturing of electrical wiring. However, steel coils can be used in the production of wire drawing machines, which are used to stretch and shape the copper or aluminum wire used in electrical wiring.

- Q: Several reading methods of steel tape measure

- Direct reading method when measuring the steel tape zero scale alignment measurement starting point, proper tension (stretching force with steel tape tension or tension on the calibration ruler identification shall prevail, with the spring balance measure), direct reading measurement end point corresponding to the scale scale.

- Q: They are showing on tv a special on how the new World Trade Center, building 1, is being built. Focusing on the steel and the guys fitting everything together.Where do builders go to buy all that steel framing? We do not build really tall buildings where I live so most of the steel is cut and welded on the job site. At World Trade Center 1, they seem to get the steel on trucks; already cut and welded.

- The steel is all custom fabricated in what are called structural steel fabrication shops. Each Building is designed by architects then the frame is designed by engineers to support whatever load is being applied to the building. After the engineering is done it goes out for a bid package where a fab shop estimates how much to charge for the fabrication of the steel and the erection of the steel. Once a company wins the bid, it then has to design how the steel will connect with one another and have it approved by an engineering firm to assure the connections are strong enough. Once all of that happens the fab shop orders raw steel beams and angle iron and steel plate at stock lengths. Beams are then cut into the right length and holes drilled in the proper places. The beam is then marked with a number that tells the erectors where it goes. The steel is then shipped out in batches to the construction site where it is unloaded and shook out into an organized place to grab them with a crane. They are then put together like a toy model, there are instructions that say what beam goes where and what size bolt to use. The welding you see being done is on really critical moments that need extra strength. That is about how it goes in a nutshell. It is a bit more complicated than that but it gives you an idea.

- Q: i want to know if i should buy a set of acrylic tapers or steel. they r close in cost so it's not a money factor i want to know which work better and if there is a downside to either. thanks!

- It relies upon on your physique and what you desire. in case you physique is allergic to a minimum of one in all them you may would desire to chosen for yet another one. If this is not any longer allergic to any, than you need to use in spite of you like the main, in simple terms attempt the two.

- Q: How are steel coils used in the production of steel hinges?

- Steel coils are used in the production of steel hinges as they serve as the primary raw material. These coils are cut, shaped, and formed into the desired hinge shape using various manufacturing techniques. The versatility and strength of steel coils make them ideal for creating durable and reliable hinges that can withstand regular use and provide smooth operation.

- Q: Are steel coils used in shipbuilding?

- Yes, steel coils are commonly used in shipbuilding. They are used primarily for the construction of the ship's hull and other structural components due to their strength, durability, and ability to withstand harsh marine environments.

- Q: I have a steel string, Yamaha acoustic guitar that I am learning to play at home. But at school I use a rented nylon string guitar. I like the feel of the nylon strings better then the steel strings and i was wondering if i can just switch strings or if i should just get another guitar. Can anyone help?

- As okorder /..

Send your message to us

Prepainted GI steel Coil/ PPGI / PPGL/ Color Coated Galvanized Steel Sheet in Coi/PPGI/SGCC/SGLCC

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords