Hot Rolled unequal Angle Steel used for Stiffeners

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m.t.

- Supply Capability:

- 220000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description:

Specifications of Hot Rolled unequal Angle Steel uased for Stiffeners

1.Standards:GB,

2. Invoicing on theoretical weight or actual weight as customer request3.Material:GBQ235B,Q345BorEquivalent;ASTMA36;EN10025.

4. Payment terms:

1).100% irrevocable L/C at sight.

2).35% T/T prepaid and the balance against the copy of B/L.

3).35% T/T prepaid and the balance against L/C

5.Sizes:

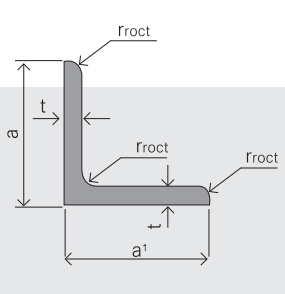

EQUAL ANGLES SIZES |

| ||

a(mm) | a1(mm) | thickness(mm) | length |

50 | 50 | 3.7---6.0 | 6M/9M/12M |

60 | 60 | 5.0---6.0 | 6M/9M/12M |

70 | 70 | 6.0---7.0 | 6M/9M/12M |

75 | 75 | 5.0---10.0 | 6M/9M/12M |

80 | 80 | 6.0---10.0 | 6M/9M/12M |

100 | 100 | 6.0---12.0 | 6M/9M/12M |

120 | 120 | 8.0-12.0 | 6M/9M/12M |

125 | 125 | 8.0---12.0 | 6M/9M/12M |

130 | 130 | 9.0-12.0 | 6M/9M/12M |

140 | 140 | 10.0-16.0 | 6M/9M/12M |

150 | 150 | 10---15 | 6M/9M/12M |

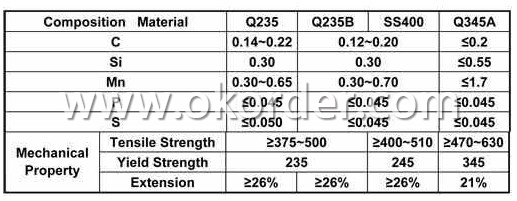

6. Material details:

Usage & Applications Hot Rolled Angle Steel

According to the needs of different structures, Angle can compose to different force support component. It is widely used in various building structures and engineering structures such as ships, industrial furnaces, reaction tower, container frame and warehouse etc.

Packaging & Delivery

1. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 30MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

2. With bundles and 20 feet and 40 feet container, or by bulk cargo, also we could do as customer's request.

- Q: What are the different methods of surface protection for steel angles?

- There are several methods available for surface protection of steel angles, including painting, galvanizing, powder coating, and applying protective coatings such as epoxy or polyurethane. Each method offers varying degrees of protection against corrosion and damage, depending on the specific requirements and environment in which the steel angles will be used.

- Q: Can steel angles be used in automotive applications?

- Indeed, automotive applications can make use of steel angles. The automotive industry frequently employs steel angles for a multitude of purposes, including frames, chassis, supports, brackets, and reinforcements. The reason behind this preference lies in the fact that steel angles possess exceptional strength, durability, and resistance to impact and vibrations. Consequently, they prove suitable for enduring the challenging conditions and demanding loads that arise within automotive applications. Furthermore, the ease with which steel angles can be welded or bolted together grants designers and constructors flexibility when designing and constructing automotive components. On the whole, due to their strength, versatility, and capacity to withstand the industry's rigorous demands, steel angles represent a dependable and cost-effective choice for automotive applications.

- Q: What are the different types of steel angles used in shelving units?

- There are typically two types of steel angles used in shelving units: equal angles and unequal angles. Equal angles have equal sides and are commonly used for standard shelving configurations. Unequal angles have one longer side and one shorter side, which allows for customized shelving arrangements to accommodate different storage needs.

- Q: What are the tolerances for steel angles?

- The tolerances for steel angles can vary depending on the specific grade and manufacturing standards. However, in general, the tolerances for steel angles typically include dimensional tolerances such as length, width, and thickness. These tolerances ensure that the steel angles meet the required specifications and can be used effectively in various applications. For length, the tolerance usually ranges from ±1/8" to ±1/4", depending on the size and grade of the angle. This means that the actual length of the angle can vary within this range from the specified length. Similarly, for width, the tolerance can range from ±1/8" to ±1/4", ensuring that the actual width of the angle falls within this range from the specified width. In terms of thickness, the tolerance can vary depending on the manufacturing process and the grade of the steel angle. However, common tolerances for thickness can range from ±1/16" to ±1/8". This tolerance ensures that the actual thickness of the angle is within this range from the specified thickness. It is important to note that these tolerances are general guidelines and may vary depending on the specific requirements and standards set by manufacturers or industry regulations. Therefore, it is always recommended to refer to the product specifications or consult with the manufacturer for accurate and up-to-date information on tolerances for steel angles.

- Q: Are steel angles resistant to chemical corrosion?

- Yes, steel angles are resistant to chemical corrosion to some extent. Steel is known for its strength and durability, but it can still corrode when exposed to certain chemicals and corrosive environments. However, steel angles are often coated or treated with protective materials such as galvanization, which significantly enhances their resistance to chemical corrosion. Galvanized steel angles have a layer of zinc applied to their surface, which acts as a barrier against corrosive substances. This coating helps to prevent the steel from coming into direct contact with chemicals, thus reducing the risk of corrosion. Nonetheless, it is important to note that the level of resistance may vary depending on the specific chemical and the duration and intensity of exposure. Regular maintenance and inspection are necessary to ensure the long-term corrosion resistance of steel angles.

- Q: What are the limitations of using steel angles in certain applications?

- When considering the utilization of steel angles in specific applications, one must take into account several limitations. To begin with, steel angles may not be suitable for applications that necessitate high strength or load-bearing capacities. While steel angles are generally robust and long-lasting, they may not be capable of withstanding exceedingly heavy loads or forces. In such instances, alternative types of structural steel sections, such as I-beams or hollow sections, may be more appropriate. Additionally, steel angles may not be ideal for applications that require precise dimensions or tight tolerances. Due to the manufacturing process, steel angles can exhibit slight variations in size and shape, which may be unacceptable in certain applications. In these circumstances, it may be necessary to utilize custom-made or precision-machined steel components. Moreover, steel angles may possess limitations in terms of corrosion resistance. If the application involves exposure to harsh environments, such as marine or chemical settings, the steel angles may deteriorate over time. In such situations, materials with superior corrosion resistance, such as stainless steel or aluminum, may be more suitable. Lastly, steel angles may not deliver the desired aesthetic appearance in certain applications. Although steel angles are commonly employed in structural and industrial settings, they may not be visually appealing or compatible with architectural or decorative applications. In these cases, alternative materials or finishes may be preferred to achieve the desired aesthetics. In summary, while steel angles offer numerous advantages in terms of strength, versatility, and cost-effectiveness, they do have limitations in certain applications. It is crucial to thoroughly evaluate the specific requirements of the application and consider these limitations before deciding to utilize steel angles.

- Q: Can steel angles be used in outdoor or exposed applications?

- Yes, steel angles can be used in outdoor or exposed applications. Steel is a highly durable and weather-resistant material, making steel angles suitable for withstanding outdoor conditions. Additionally, steel angles can be treated or coated to provide further protection against rust and corrosion, making them a reliable choice for outdoor and exposed applications.

- Q: Can steel angles be used in the construction of schools?

- Yes, steel angles can be used in the construction of schools. Steel angles are versatile and commonly used in construction projects due to their strength and durability. They can be used for various purposes, such as framing, support beams, and reinforcement. Steel angles provide stability and structural integrity to the building, making them suitable for use in schools where safety and longevity are important factors. Additionally, steel angles are fire-resistant, which is crucial in ensuring the safety of students and staff. Overall, steel angles are a reliable and cost-effective choice for constructing schools.

- Q: Are steel angles resistant to termites and pests?

- No, steel angles are not resistant to termites and pests. Steel angles, being made of metal, are not attractive to termites as they do not provide a food source. However, termites can still cause damage to surrounding materials such as wood or insulation, which may be present in the structure where the steel angles are used. It is important to ensure that the overall construction is termite-resistant and appropriate measures are taken to prevent infestations.

- Q: What is the maximum temperature that steel angles can withstand?

- The maximum temperature that steel angles can withstand depends on the grade of steel used. Generally, low carbon steel angles can withstand temperatures up to 600-700 degrees Celsius (1112-1292 degrees Fahrenheit) before their mechanical properties begin to deteriorate. However, higher carbon steels, stainless steels, or alloy steels can withstand higher temperatures, ranging from 800-1200 degrees Celsius (1472-2192 degrees Fahrenheit) or even higher. It is important to consult the specific material specifications or consult with a materials engineer to determine the maximum temperature a particular steel angle can withstand in a specific application.

Send your message to us

Hot Rolled unequal Angle Steel used for Stiffeners

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m.t.

- Supply Capability:

- 220000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords