Hot Rolled Steel Plate Mild Steel Chequered Plate

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 23 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

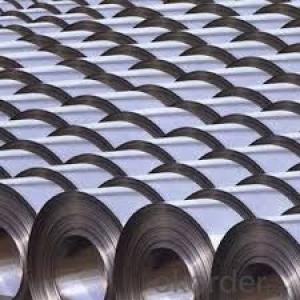

Hot rolled steel plate mild steel chequered plate

Our main procucts are steel billet,steel plate,steel roll coil,steel wire rod,steel bar,etc.Moreover,our hot rolled coil and ship building plate are certificated respectively by CARES,CE from Eurpoean Union and CCS authentication from nine nations.Our products are widely used in variety areas,such as millitary,aerospace,transportation,equipment manufacturing,shipping,petroleum pipe line,buildings,etc.

Product Description

| Item Name | Boiler steel plate(pressure vessel steel plate) | |||||||

| Standard | ASTM515/516,EN10028-2,GB713,GB3531 | |||||||

| Certification | ISO9001 | |||||||

| Dimension | Thickness:6mm-50mm,as customer's requirement | |||||||

| Width:1700mm-3200mm,as customer's requirement | ||||||||

| Length:3000mm-13000mm,as customer's requirement | ||||||||

| Surface | Clean,blasting and painting according to customer requirement | |||||||

| Application | It is widely used in Container,Boiler,Construction,etc | |||||||

Product Picture

FAQ

1.Q:You are Factory or Trading Company?

A:We are factory,our main products include Steel plate,Steel Bar,Steel coils.

2.Q:What’s the MOQ?

A:Generally,the trail order will be accepted.The MOQ can be confirmed according to the different products.For example,the MOQ of rebar will be 25-50MT,the galvanized steel pipe will be 10MT,the stainless steel pipe will 1-5MT.

3.Q:Do you have OEM service?

A: Yes.Variety of products size,quality and quantity can be customized according to your need.

4.Q:Could you support free sample?

A:Yes.We can supply FREE samples.But the delivery charges will be covered by our customers.

5.Q:How about the delivery time?

A:Within 15-30days after receiving the deposit or L/C at sight.

6.Q:How about the trade terms?

A:EXW,FOB,CFR,CIF will be accepted.

7.Q:How about your payment terms?

A:30%TT in advance and the balance against of copy of B/L.

The irrevocable L/C at sight will be accepted.

- Q: Are steel sheets suitable for roofing systems?

- Yes, steel sheets are suitable for roofing systems. Steel is a durable and long-lasting material that offers excellent protection against weather elements, such as rain, snow, and hail. It is also fire-resistant and can withstand high winds. Additionally, steel sheets are lightweight, making them easier to install and maintain.

- Q: Can steel sheets be used for manufacturing machinery parts?

- Yes, steel sheets can be used for manufacturing machinery parts. Steel is a strong and durable material that is commonly used in the manufacturing industry for various applications, including machinery parts. Steel sheets can be easily formed, cut, and welded to create complex shapes and structures required for machinery components. Additionally, steel offers excellent mechanical properties such as high tensile strength and resistance to wear, which are crucial for machinery parts that are subjected to heavy loads and frequent use.

- Q: Can steel sheets be used in high-temperature environments?

- Yes, steel sheets can be used in high-temperature environments. Steel has a high melting point and excellent heat resistance, making it suitable for various applications where extreme temperatures are involved, such as in industrial furnaces or automotive exhaust systems.

- Q: Are the steel sheets suitable for automotive applications?

- Yes, steel sheets are highly suitable for automotive applications. Steel is widely used in the automotive industry due to its exceptional strength, durability, and versatility. It offers excellent crash resistance, making it ideal for vehicle structures to ensure passenger safety. Additionally, steel sheets can be easily formed into complex shapes, allowing for the production of various automotive components such as body panels, chassis, and frames. Steel also provides good corrosion resistance, which is crucial for withstanding harsh environmental conditions. Moreover, it is cost-effective and readily available, making it a popular choice for automakers. Overall, steel sheets are a reliable and suitable material for automotive applications.

- Q: Do the steel sheets have any specific fire ratings?

- Steel sheets can indeed possess specific fire ratings, as their ability to withstand fire and prevent flame propagation determines their classification. These ratings, typically categorized according to the duration the steel sheets can resist fire before succumbing to penetration or collapse, commonly span 30, 60, 90, and 120 minutes. Rigorous tests are employed to determine these ratings, evaluating the steel sheets' performance under fire conditions, including exposure to intense temperatures and flames. To guarantee compliance with the necessary safety standards for your intended purpose, it is crucial to consult the manufacturer or supplier for the exact fire ratings of the steel sheets.

- Q: Can steel sheets be used for toolboxes and cabinets?

- Yes, steel sheets can be used for toolboxes and cabinets. Steel is a durable and strong material, making it suitable for creating sturdy toolboxes and cabinets that can withstand heavy use and provide ample storage space.

- Q: Are steel sheets available in different colors?

- Yes, steel sheets are available in different colors.

- Q: How are steel sheets protected against rusting?

- Steel sheets are protected against rusting through a process called corrosion protection. There are several methods used to protect steel sheets from rust, including: 1. Galvanization: This process involves coating the steel sheets with a layer of zinc. Zinc acts as a sacrificial anode, meaning it corrodes in place of the steel when exposed to moisture or oxygen. This creates a barrier that protects the steel from rusting. 2. Painting: Applying a layer of paint to steel sheets acts as a protective barrier against moisture and oxygen. The paint creates a physical barrier that prevents these elements from coming into contact with the steel, thus reducing the risk of rust formation. 3. Powder coating: Powder coating involves applying a dry powder to the steel sheets and then heating it to form a protective layer. The powder melts and fuses into a smooth coating, providing excellent resistance to rust and corrosion. 4. Electroplating: This method involves immersing the steel sheets in a bath containing a metal coating solution, such as zinc or chromium. An electric current is then passed through the bath, causing the metal coating to bond with the steel. This electroplated layer acts as a protective barrier against rust. 5. Phosphating: Phosphating is a chemical process where a layer of zinc or manganese phosphate is deposited on the steel sheets. This layer enhances the adhesion of paint or other coatings, providing a corrosion-resistant surface. These methods are commonly used in various industries to protect steel sheets from rusting. The specific method chosen depends on factors such as cost, durability requirements, and the environment in which the steel sheets will be used.

- Q: How do steel sheets handle impact resistance?

- Steel sheets are known for their exceptional impact resistance. Due to their high strength and toughness, steel sheets can effectively absorb and distribute the energy produced by an impact, minimizing the damage caused. This is primarily attributed to the microstructure of steel, which consists of a crystalline lattice that allows for the deformation and reformation of the material under stress. When subjected to an impact, steel sheets undergo plastic deformation, which enables them to absorb the energy and prevent it from propagating further. The ability of steel sheets to handle impact resistance is further enhanced by their composition, which often includes alloying elements such as manganese, chromium, and nickel. These elements increase the hardness and strength of the steel, making it even more resistant to deformation and fracture. As a result, steel sheets are widely used in various applications where impact resistance is crucial, including automotive manufacturing, construction, and heavy machinery industries.

- Q: Are the steel sheets resistant to vibration or shock?

- Steel sheets are generally resistant to vibration and shock due to their high strength and durability. Steel is known for its ability to withstand external forces like vibrations and shocks, thanks to its rigid nature. This allows steel to effectively absorb and distribute energy caused by vibrations or shocks, preventing any significant damage or deformation. In various industries, such as construction, automotive, and aerospace, steel sheets are commonly used because their resistance to vibrations and shocks is crucial. However, it's important to consider that the exact resistance of steel sheets to vibration or shock depends on factors like thickness, steel quality, and the specific magnitude and frequency of the vibrations or shocks.

Send your message to us

Hot Rolled Steel Plate Mild Steel Chequered Plate

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 23 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords