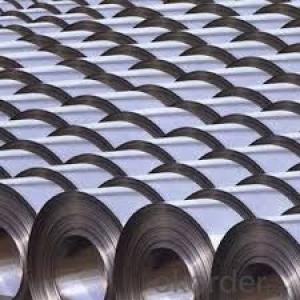

Hot Rolled Steel Coil /Cold Rolled Steel Coil/color steel rolled

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot rolled coils/plates

Type: steel coil and steel plates

Material: SS400-Q235-Q345-SPHC

Width:1250mm 1500mm 1800mm 2000mm

HOT-ROLLED COIL/PLATES(Material: SS400-Q235A/B-SPHC) | |||

2.00*1250/1500L | 3.50*1250/1500L | 5.75*1250/1500L | 11.50*1250/1500L |

2.30*1250/1500L | 3.75*1250/1500L | 7.50*1250/1500L | 11.75*1250/1500L |

2.50*1250/1500L | 4.50*1250/1500L | 7.75*1250/1500L | 13.50*1250/1500L |

2.75*1250/1500L | 4.75*1250/1500L | 9.50*1250/1500L | |

3.00*1250/1500L | 5.50*1250/1500L | 9.75*1250/1500L | |

PATTERN-ROLLED COIL/PLATES(Material: Q235A-Q235B) | |||

3.00*1250L | 3.75*1250L | 4.75*1250L | 5.75*1250L |

3.50*1250L | 4.50*1250L | 5.50*1250L | 7.50*1250L |

MIDDEL-PLATE(Material: Q235A/B-Q345A/B) | |||

8*1800/2000L | 16*1800/2000L | 25*1800/2000L | 45*1800/2000L |

10*1800/2000L | 18*1800/2000L | 30*1800/2000L | 50*1800/2000L |

12*1800/2000L | 20*1800/2000L | 35*1800/2000L | |

14*1800/2000L | 221800/2000L | 401800/2000L | |

Name | galvanized steel coil dx52d z gi |

Grade | GB/T-12754: 2006, JIS3302, EN 10142, ASTM A653, JIS G3302, SGCC/SGCH, GB/T2518, European Standard, ASTM A792, JIS G3321, JIS G3317 |

BASE PLATE | Cold rolled steel sheet, hot dipped zinc coated steel sheet hot dipped A-Z coated steel sheet |

EQUIPMENT | Double coating double baking; |

CAPACITY | 5000Mt/week |

SIZE | Thickness 0.18mm—2mm, width 40mm—1250mm |

ZINC COATING | 40g-275g /m2 |

PAINT THICKNESS | Top:20+-5um, back:5-7um |

COIL WGT | 3Mt - 8Mt |

COIL ID | φ508mm,φ610mm |

BASE SHEET | Cold rolled steel sheet, hot dipped zinc coated steel sheet (small, regular or zero spangle), hot dipped A-Z coated steel sheet |

SURFACE PAINT | EP, PE, HDP, SMP, PVDF |

COLOR SERIES | RAL color number series |

Applications of cold rolled steel sheet coil :

1) Automotive bodies: filters, fuel tanks, etc.

2) Construction materials: roofings, welding pipes,

3) Electric and electronic appliances: computer cans, etc.

4) Steel cans: containers, etc.

5) Steel furniture: washing machines, refrigerators, microwaves, etc.

6) Drums

7) Office equipment: printer, recorders, etc.

8) Motors and transformers

Process of cold rolled steel sheet coil :

Pay off reel-double cut shear-welder-notcher-entry accumulator-pre cleaning section-furnace-hot bridle-zinc pot-air knife-after cooler-water quench-dryer- skin pass mill-dryer-tension leveler-dryer-chemical coater-chemical oven-cooler-exit accumulator-oiler-exit shear-tension reel.

Features of cold rolled steel sheet coil :

1) cold rolled steel coils prices is manufactured to have a long durability, strong corrosion resistance and shiny surface.

2) cold rolled steel coils prices features excellent forming properties, paintability, weldability, and is suitable for fabrication by forming, pressing and bending.

Q&A Acceptable payment term and way ?

ANSWER: T/T,L/C, T/T + L/C, D/P

Q&A Do you accept OA payment terms?

ANSWER: Yes, sure, but it normally depending on the order value

Q&A Do you have QC team?

ANSWER: Yeah, sure, our QC team is very important, they will keep the quality control for our products.

- Q: Can steel sheets be used for food processing equipment?

- Steel sheets are indeed capable of being utilized for food processing equipment. People often favor stainless steel for such equipment because of its ability to endure, resist corrosion, and facilitate easy cleaning. Furthermore, stainless steel does not react with food nor does it impart any undesirable flavors or odors. Steel sheets can be molded into various shapes and sizes, rendering them suitable for different kinds of food processing equipment including mixers, conveyors, tanks, and cutting blades. Moreover, stainless steel also possesses resistance to high temperatures, thus making it perfect for applications involving heat. In conclusion, steel sheets are a dependable and sanitary material option for food processing equipment.

- Q: How to introduce carbon steel plate?

- Grade: the cases of Q235-A F, said the sigma s Note: Q is more than 235MPa grade yield strength of A grade (ABCD four), F boiling steel characteristics: low price, process performance (such as welding and excellent cold formability). Applications: general engineering structures and general mechanical parts. Such as Q235 can make bolts, nuts, pins, hooks and less important mechanical parts, as well as the construction of the thread steel, steel, steel and so on

- Q: What are the different sheet metal cutting techniques for steel sheets?

- There are several different sheet metal cutting techniques that can be used for steel sheets. Some of the most common methods include shearing, laser cutting, plasma cutting, and waterjet cutting. Shearing involves the use of a mechanical shear to cut the steel sheet along a straight line. Laser cutting uses a high-powered laser beam to melt and vaporize the steel, creating a precise and clean cut. Plasma cutting utilizes a plasma torch to heat and melt the steel, while a high-velocity jet of ionized gas blows the molten metal away. Waterjet cutting involves the use of a high-pressure stream of water mixed with abrasive particles to erode and cut through the steel sheet. Each technique has its own advantages and limitations, depending on factors such as the thickness of the steel, desired precision, and cost considerations.

- Q: What is the typical lead time for steel sheet orders?

- The typical lead time for steel sheet orders can vary depending on various factors such as the quantity and size of the order, the availability of the specific steel sheet, and the location of the supplier. In general, lead times for steel sheet orders can range from a few days to several weeks. For smaller orders or readily available steel sheets, the lead time is often shorter, typically around a week or less. This is because suppliers usually have these items in stock and ready to be shipped upon receiving an order. On the other hand, larger or custom orders may require additional production time and can have longer lead times. This is because the supplier may need to manufacture the steel sheets according to the specific requirements of the order, which can take several weeks depending on the complexity and volume. It is important to note that lead times can also be influenced by external factors such as market demand, transportation delays, or unforeseen circumstances. Therefore, it is recommended to communicate with the supplier directly to get an accurate estimate of the lead time for a specific steel sheet order.

- Q: Can steel sheets be used in the telecommunications industry?

- Indeed, the telecommunications industry can make use of steel sheets. Given their strength, durability, and capability to safeguard delicate equipment, steel sheets find frequent application in various sectors of the telecommunications industry. They are commonly utilized in the production of communication towers, antenna mounts, equipment cabinets, and enclosures. By providing structural support, steel sheets prove resilient against severe weather conditions, including powerful winds, extreme temperatures, and heavy loads. Furthermore, steel sheets can be conveniently fabricated and tailored to meet specific demands, rendering them a favored option within the telecommunications industry.

- Q: Can steel sheets be used for fencing applications?

- Yes, steel sheets can be used for fencing applications. Steel sheets are commonly used in fencing projects due to their durability and strength. They offer better protection and security compared to other materials like wood or PVC. Steel sheets can be welded or bolted together to create a solid and secure fence. They are resistant to weathering, corrosion, and damage from pests or animals. Steel sheets can also be customized and painted in different colors to match the aesthetic requirements of the fencing project. Overall, steel sheets are a popular choice for fencing applications due to their long-lasting nature and ability to provide a high level of security and privacy.

- Q: Can steel sheets be used in agricultural applications?

- Yes, steel sheets can be used in agricultural applications. They are often used for building structures such as barns, sheds, and fences. Steel sheets provide durability, strength, and protection against weather conditions, making them suitable for various agricultural needs.

- Q: How do steel sheets perform in fire-rated applications?

- Steel sheets perform well in fire-rated applications due to their high melting point and excellent structural integrity. When exposed to fire, steel sheets maintain their strength and stability, making them a reliable choice for fire-resistant construction. Moreover, steel sheets do not contribute to the spread of fire or the release of toxic fumes, enhancing the safety of occupants during a fire incident. Additionally, steel sheets offer excellent thermal insulation, helping to prevent the transfer of heat from the fire to other areas of the building. This property allows for the containment of fires and limits the damage caused. Overall, the use of steel sheets in fire-rated applications provides a robust and effective solution for fire protection in buildings.

- Q: What is the difference between a perforated and expanded steel sheet?

- A perforated steel sheet and an expanded steel sheet are both types of metal sheets commonly used in various industries. However, they differ in terms of their manufacturing process and resulting characteristics. Perforated steel sheets are created by punching or drilling holes into a solid steel sheet. These holes can be of various shapes, sizes, and patterns, depending on the desired application. The holes in a perforated steel sheet allow for the passage of air, light, sound, or fluids, making them suitable for applications that require ventilation, filtration, or acoustic properties. Perforated steel sheets are commonly used in industries such as architecture, automotive, filtration, and mining. On the other hand, expanded steel sheets are produced by a unique manufacturing process known as expanding. The process involves cutting and stretching a solid steel sheet, resulting in a mesh-like pattern with diamond-shaped openings. The stretching process imparts strength and rigidity to the steel sheet while also reducing its weight. Expanded steel sheets are versatile and can be used in applications such as walkways, platforms, fencing, grating, and reinforcement. In summary, the main difference between a perforated and expanded steel sheet lies in their manufacturing process and resulting characteristics. Perforated steel sheets have holes punched or drilled into them, allowing for the passage of air, light, sound, or fluids. Meanwhile, expanded steel sheets are created by cutting and stretching a solid sheet, resulting in a mesh-like pattern with diamond-shaped openings. Both types of sheets have their unique advantages and are chosen based on the specific requirements of the application.

- Q: Can steel sheets be used for storage racks?

- Indeed, storage racks can indeed be made using steel sheets. Renowned for their robustness and strength, steel sheets are an optimal choice when it comes to constructing storage racks. They possess the ability to bear substantial weights and offer steadfastness to the entire storage system. Furthermore, steel sheets can be effortlessly fabricated and tailored to suit the precise specifications of the storage area. Moreover, steel exhibits resistance against corrosion, guaranteeing the durability of the storage racks and rendering them suitable for employment indoors as well as outdoors.

Send your message to us

Hot Rolled Steel Coil /Cold Rolled Steel Coil/color steel rolled

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords