Hot Rolled Stainless Steel Sheet With Competitiver Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 6 m.t.

- Supply Capability:

- 4000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

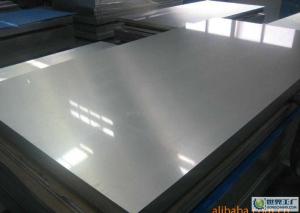

1.Structure of Product Description

Stainless steel sheet/stainless steel plate/stainless steel slabs are all widely used in the field of construction field and decoration field, etc. The detailed grade are as follows: 201, 202, 301, 304, 316, 410, 420, 430, etc.

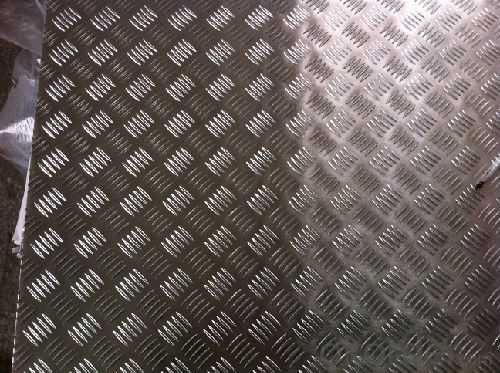

The surface is including 2B, BA, Mirror Finish, Checkered, etc.

2. Main features of the product

a. Competitive price

b. Frist-Class Service.

c. Shortest service.

3. Image.

4. Product detailed sizes:

500mm*1000mm, 1000mm*2000mm, 1500mm*3000mm,1500mm*6000mm, etc.

5. FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006 or else.

What is the width range?

---It is from 1000mm to 2500mm, etc.

What is the length range?

---It is from 2000mm to 6000mm, etc.

What is the MOQ for your products yet?

---Normally it is around 3 tons/each size.

How many tons did you export in one year?

---Normally it is around 9000 tons totally.

Where is your client from?

---Normally it is from Japan, USA, ENGLISH, SINGAPORE, ETC.

stainless steel checkered sheet, stainless steel mirror finished sheet, color coated stainless steel sheet, etc.

- Q: Are stainless steel sheets suitable for chemical transport containers?

- Indeed, chemical transport containers can rely on stainless steel sheets. Renowned for its exceptional resistance to corrosion, stainless steel proves highly appropriate for chemical transportation. Its ability to withstand numerous acids, alkalis, and corrosive substances guarantees the preservation and purity of the chemicals throughout transit. Moreover, stainless steel sheets boast durability and strength, delivering structural integrity to the containers and ensuring the secure transportation of chemicals.

- Q: Are stainless steel sheets suitable for oil refineries?

- Indeed, oil refineries find stainless steel sheets to be a suitable option. This is due to stainless steel's commendable resistance to corrosion, ability to withstand high temperatures, and durability. These qualities render it highly compatible with the harsh conditions encountered in oil refineries, where the presence of corrosive chemicals, elevated temperatures, and constant exposure to moisture can prove detrimental to alternative materials. Commonly utilized within oil refineries, stainless steel sheets serve various purposes such as storage tanks, pipelines, heat exchangers, and other equipment that necessitate corrosion resistance. Furthermore, the ease of cleaning and maintenance of stainless steel sheets plays a pivotal role in preserving the efficiency and functionality of equipment within oil refineries.

- Q: How do you prevent galvanic corrosion on stainless steel sheets?

- One way to prevent galvanic corrosion on stainless steel sheets is to ensure that they are not in direct contact with dissimilar metals. This can be achieved by using insulating materials, such as rubber gaskets or plastic washers, between the stainless steel sheets and any other metal surfaces they come into contact with. Additionally, regular cleaning and maintenance of the stainless steel sheets can help remove any potential corrosive agents and minimize the risk of galvanic corrosion.

- Q: Can stainless steel sheets be used for electromagnetic shielding?

- Indeed, electromagnetic shielding can indeed be achieved through the utilization of stainless steel sheets. The remarkable conductivity of stainless steel allows it to proficiently obstruct or weaken electromagnetic radiation. By employing stainless steel sheets as a protective barrier, the infiltration of electromagnetic fields can be effectively hindered, consequently safeguarding vulnerable electronic devices, machinery, or areas from any potential electromagnetic interference (EMI) or radio frequency interference (RFI). The utilization of stainless steel sheets is prevalent in scenarios necessitating electromagnetic shielding, such as the fabrication of enclosures or cabinets utilized in the realms of electronics, medical equipment, telecommunications, or military systems.

- Q: Can stainless steel sheets be used in marine environments?

- Yes, stainless steel sheets can be used in marine environments. Stainless steel is highly resistant to corrosion, making it suitable for marine applications where it will be exposed to saltwater and high humidity. It is commonly used in marine vessels, offshore platforms, and other structures that require durability and resistance to rust and corrosion.

- Q: Can stainless steel sheets be used for soundproofing?

- Stainless steel sheets alone are not typically used for soundproofing purposes. While stainless steel is known for its durability and corrosion resistance, it does not possess significant soundproofing properties. However, stainless steel sheets can be incorporated into soundproofing systems as part of a composite structure or in conjunction with other soundproofing materials to enhance their overall effectiveness.

- Q: What are the different types of stainless steel sheet embossing patterns available?

- There are several different types of stainless steel sheet embossing patterns available. Some of the most common patterns include: 1. Diamond: This pattern features a series of diamond-shaped indentations evenly spaced across the surface of the sheet. It creates a visually appealing and textured appearance. 2. Linen: The linen pattern resembles the texture of linen fabric, with a series of parallel lines running in one direction and perpendicular lines intersecting them. It adds a subtle and sophisticated look to stainless steel sheets. 3. Stucco: The stucco pattern creates a raised, pebble-like texture on the surface of the sheet. It is commonly used in architectural applications to add visual interest and a tactile feel. 4. Leather: This pattern replicates the texture of leather, with a series of irregular lines and indentations. It provides a unique and luxurious appearance to stainless steel sheets. 5. Hammered: The hammered pattern features a series of irregular indentations that resemble the marks made by a hammer. It adds a rustic and handcrafted look to stainless steel sheets. 6. Checkerboard: This pattern consists of a grid of squares, with alternating squares raised or recessed. It creates a classic and geometric design on stainless steel sheets. 7. Wave: The wave pattern features a series of curved lines that resemble ocean waves. It adds a dynamic and flowing look to stainless steel sheets. These are just a few examples of the many different types of stainless steel sheet embossing patterns available. Each pattern can be customized in terms of size, depth, and spacing to suit specific design preferences and applications.

- Q: Can stainless steel sheets be used in outdoor applications?

- Yes, stainless steel sheets can be used in outdoor applications. Stainless steel is highly resistant to corrosion and oxidation, making it an ideal choice for outdoor use. It can withstand harsh weather conditions, including rain, snow, and UV radiation, without rusting or deteriorating. Additionally, stainless steel is highly durable and can withstand heavy loads and impacts, making it suitable for various outdoor applications such as cladding, roofing, fencing, and decorative elements. Its aesthetic appeal and low maintenance requirements also make it a popular choice for outdoor applications.

- Q: Are stainless steel sheets resistant to staining?

- Yes, stainless steel sheets are highly resistant to staining. This is because stainless steel contains a high percentage of chromium, which forms a protective layer on the surface of the metal. This layer, known as the passive layer, prevents the steel from reacting with oxygen and moisture in the environment, making it resistant to rust and corrosion. Additionally, the smooth and non-porous surface of stainless steel makes it difficult for stains to penetrate and adhere to the material. While stainless steel sheets may still show some signs of staining over time, they can be easily cleaned and restored to their original appearance with minimal effort. Overall, stainless steel sheets are a popular choice for applications where stain resistance is important, such as in kitchens, hospitals, and industrial settings.

- Q: How do I determine the flatness of stainless steel sheets?

- To determine the flatness of stainless steel sheets, you can follow these steps: 1. Visual Inspection: Start by visually inspecting the sheet for any visible signs of warping, bending, or unevenness. Look for any noticeable waves, ripples, or twists in the surface. While this method may not be the most accurate, it can give you an initial idea of the sheet's overall flatness. 2. Measuring with a Straight Edge: Place a straight edge, such as a ruler or a long level, on the surface of the stainless steel sheet. Move the straight edge across different areas of the sheet, focusing on both the center and the edges. Observe if there are any gaps or spaces between the straight edge and the sheet. If the straight edge remains in full contact with the sheet throughout, it indicates a good level of flatness. 3. Using a Feeler Gauge: A feeler gauge is a precision measurement tool consisting of a set of thin metal blades of varying thicknesses. It can be used to measure the gap between the straight edge and the stainless steel sheet more accurately. Slide the feeler gauge into any gaps between the sheet and the straight edge, noting the blade thickness that fits snugly. This will help determine the extent of any unevenness or bowing present. 4. Laser Measurement: For more precise measurements, you can use a laser measuring device. Place the laser device on one end of the sheet and measure the distance from the laser to the surface at various points along the length of the sheet. Repeat this process on the opposite end of the sheet. Comparing these measurements will give you an indication of any differences in flatness. 5. Professional Testing: If the stainless steel sheets are intended for critical applications or if precise flatness is crucial, it may be wise to consult with a professional testing service. They can utilize advanced techniques such as optical profilometry or coordinate measuring machines to accurately measure the flatness of the sheet. It is important to note that due to the inherent characteristics of stainless steel, some slight deviations from perfect flatness may be acceptable within industry standards. The level of flatness required will depend on the specific application and the tolerance standards set by the manufacturer or customer.

Send your message to us

Hot Rolled Stainless Steel Sheet With Competitiver Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 6 m.t.

- Supply Capability:

- 4000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords