Hot Rolled Steel Equal Angle High Quality

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Angle Bar at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

According to the needs of different structures, Angle can compose to different force support component, and also can be the connections between components. It is widely used in various building structures and engineering structures such as roof beams, bridges, transmission towers, hoisting machinery and transport machinery, ships, industrial furnaces, reaction tower, container frame and warehouse etc.

.

Product Advantages:

OKorder's Angle Bar are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

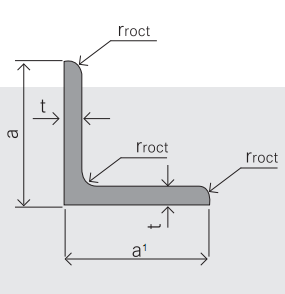

Product Specifications:

1. Invoicing on theoretical weight or actual weight as customer request

2. Length: 6m, 9m, 12m as following table

3. Sizes

Sizes: 25mm-250mm | ||

a*t | ||

25*2.5-4.0 | 70*6.0-9.0 | 130*9.0-15 |

30*2.5-6.6 | 75*6.0-9.0 | 140*10-14 |

36*3.0-5.0 | 80*5.0-10 | 150*10-20 |

38*2.3-6.0 | 90*7.0-10 | 160*10-16 |

40*3.0-5.0 | 100*6.0-12 | 175*12-15 |

45*4.0-6.0 | 110*8.0-10 | 180*12-18 |

50*4.0-6.0 | 120*6.0-15 | 200*14-25 |

60*4.0-8.0 | 125*8.0-14 | 250*25 |

4. Chemical data: %

C | Mn | S | P | Si |

0.14-0.22 | 0.30-0.65 | ≤0.050 | ≤0.045 | ≤0.30 |

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Images:

- Q: How do you prevent warping of steel angles during fabrication?

- To prevent warping of steel angles during fabrication, there are several key measures that can be taken: 1. Proper material handling: Steel angles should be stored, transported, and handled carefully to avoid any bending or warping. They should be stored on a flat surface or rack, ensuring that they are not subjected to excessive pressure or force that could cause deformation. 2. Controlled heating and cooling: During fabrication processes that involve heat, such as welding or cutting, it is crucial to control the temperature and minimize the heat input. Rapid heating or cooling can lead to thermal expansion or contraction, causing warping. Proper preheating and controlled cooling methods, such as using heat sinks or heat-treating processes, should be employed to mitigate the risk of warping. 3. Proper welding techniques: Welding is a critical step in steel fabrication, and improper techniques can contribute to warping. It is essential to use appropriate welding parameters, such as correct amperage, voltage, and travel speed, to ensure a balanced heat distribution across the workpiece. Additionally, employing welding fixtures, clamps, or jigs can help hold the steel angles in place during welding, minimizing distortion. 4. Minimize stress concentration: Sharp corners or abrupt changes in geometry can create stress concentration points, which are prone to warping. It is advisable to avoid sharp corners by using radii or chamfers, which distribute stress more evenly. Furthermore, proper alignment and fit-up of the steel angles before welding can reduce residual stress and potential warping. 5. Post-welding treatments: After welding, it is essential to relieve residual stresses in the steel angles. This can be achieved through post-weld heat treatment or stress-relieving processes, such as annealing or normalizing. These treatments help to reduce internal stresses and minimize the risk of warping. Overall, a combination of proper material handling, controlled heating and cooling, appropriate welding techniques, stress minimization, and post-welding treatments can significantly contribute to preventing warping during the fabrication of steel angles.

- Q: What are the environmental benefits of using steel angles?

- Using steel angles in construction and various industries offers numerous environmental advantages. Firstly, steel is a material that is highly recyclable. The production process of steel angles involves recycling scrap steel, which reduces the need for extracting and processing new raw materials. This recycling process helps conserve natural resources and reduces the energy and water consumption associated with mining and refining metals. Furthermore, steel is renowned for its durability and long lifespan. Steel angles have a long-lasting nature and require minimal maintenance, reducing the need for frequent replacements. This durability aids in minimizing waste and the environmental impact linked to manufacturing and disposing of new materials. Moreover, steel is a non-combustible material, making it a safer choice for construction. Unlike certain other materials, steel angles do not contribute to the spread of fires, reducing the risk of environmental damage and potential harm to human health. Additionally, steel is highly energy-efficient. Steel angles can be manufactured using processes that prioritize energy efficiency, and steel structures are known for their thermal efficiency. This means that steel buildings require less energy for heating and cooling, ultimately reducing overall energy consumption and greenhouse gas emissions. Lastly, the use of steel angles can contribute to sustainable building practices. Steel structures can be designed in a manner that maximizes natural light and ventilation, reducing the need for artificial lighting and air conditioning. Furthermore, steel can be easily repurposed or recycled at the end of its lifespan, further reducing waste and environmental impact. In conclusion, the utilization of steel angles yields environmental benefits such as recyclability, durability, non-combustibility, energy efficiency, and the promotion of sustainable building practices. By opting for steel angles in construction and industrial applications, we can effectively minimize resource consumption, waste generation, and greenhouse gas emissions, thereby fostering a more sustainable and environmentally-friendly future.

- Q: How do steel angles contribute to the overall sustainability of a building?

- Steel angles contribute to the overall sustainability of a building in several ways. Firstly, steel angles are made from recycled materials, making them a sustainable option for construction. Steel is one of the most recycled materials in the world, with a high recycling rate, reducing the need for virgin resources and minimizing the environmental impact of extraction and production. Additionally, steel angles offer structural efficiency, which means that they can support larger loads with less material compared to other building materials. This efficiency reduces the amount of steel required in construction, minimizing the carbon footprint associated with steel production and transportation. Furthermore, steel angles are highly durable and long-lasting. They have a high resistance to corrosion, fire, and pests, which reduces the maintenance and replacement needs over the building's lifespan. This durability translates into reduced waste generation and lower life-cycle costs, making the building more sustainable in the long run. Moreover, steel angles are versatile and can be easily reused or repurposed. If a building needs to be renovated or demolished, the steel angles can be salvaged and reused in other construction projects. This promotes a circular economy approach and minimizes waste generation, contributing to the overall sustainability of the construction industry. Lastly, steel angles have excellent thermal properties, which can enhance the energy efficiency of a building. They can be used as part of the building envelope, helping to reduce energy consumption for heating and cooling. By improving the insulation and airtightness of a building, steel angles contribute to lower energy demand and reduced greenhouse gas emissions. In conclusion, steel angles contribute to the overall sustainability of a building through their recycled content, structural efficiency, durability, recyclability, and energy-saving properties. By choosing steel angles in construction, we can promote resource conservation, reduce waste generation, and minimize the environmental impact of the built environment.

- Q: How are steel angles protected against fire damage?

- Steel angles are commonly protected against fire damage through the application of fire-resistant coatings or the use of fireproofing materials. These protective measures aim to delay or prevent the steel from reaching its critical temperature, at which it may lose its structural integrity. One common method of protecting steel angles is the application of intumescent coatings. These coatings expand when exposed to high temperatures, forming a protective char layer that insulates the steel and slows down heat transfer. This process effectively delays the rise in temperature of the steel, allowing for longer fire resistance. Another approach is the use of fireproofing materials, such as concrete or gypsum-based sprays or boards. These materials create a barrier between the steel angles and the fire, providing insulation and preventing the heat from reaching the steel. Fireproofing materials are often used in buildings where the fire resistance requirements are higher, such as high-rise structures or industrial facilities. In some cases, steel angles can also be protected by encasing them in fire-rated enclosures. This involves enclosing the steel angles within fire-rated walls, floors, or ceilings made of materials with high fire resistance. These enclosures effectively isolate the steel from potential sources of fire and provide an additional layer of protection. It is important to note that the specific fire protection measures for steel angles may vary depending on the building codes, fire safety regulations, and the intended use of the structure. Consulting with fire protection engineers and following the appropriate guidelines can ensure that the steel angles are adequately protected against fire damage.

- Q: How do steel angles contribute to the overall stability of a building frame?

- Steel angles contribute to the overall stability of a building frame by providing structural support and reinforcement. They are commonly used as braces and connections in building frames to increase their load-bearing capacity and resist forces such as wind, earthquakes, and heavy loads. The angles help distribute and transfer the loads throughout the structure, enhancing its stability and preventing deformation or collapse.

- Q: Can steel angles be used for railings or barriers?

- Absolutely, railings or barriers can indeed utilize steel angles. In construction, steel angles are widely employed and renowned for their robustness and longevity. They furnish a solid and dependable framework for railings and barriers, guaranteeing the safety and security of the surroundings. The assembly and customization of steel angles are a breeze, as they can be effortlessly welded or bolted together. Furthermore, these angles can be coated or painted to enhance their aesthetic appeal and safeguard against rust and corrosion. All in all, owing to their strength, adaptability, and enduring nature, steel angles are a highly favored option for railings and barriers.

- Q: How do you determine the required number of fasteners for a steel angle connection?

- To determine the required number of fasteners for a steel angle connection, several factors need to be considered. These include the load being applied, the size and thickness of the angle, the type and strength of the fasteners being used, and any applicable building codes or engineering standards. Typically, calculations or guidelines provided by structural engineers or industry standards are used to determine the minimum number and spacing of fasteners needed to ensure the connection is strong and safe.

- Q: Are there any environmental benefits of using steel angles?

- Yes, there are several environmental benefits of using steel angles. Firstly, steel is one of the most recycled materials in the world. When steel angles are no longer needed, they can be easily recycled into new steel products, reducing the demand for new steel production. This recycling process requires less energy and resources compared to producing steel from raw materials, resulting in significant energy savings and reduced carbon emissions. Additionally, steel is a durable material that has a long lifespan. This means that steel angles require less frequent replacement compared to other materials, reducing the amount of waste generated. The durability of steel also means that it requires less maintenance and repairs over time, further reducing its environmental impact. Furthermore, steel is resistant to fire, pests, and rot, reducing the need for chemical treatments and preservatives that can be harmful to the environment. Steel angles also have high strength-to-weight ratio, meaning that less material is required to achieve the same structural integrity compared to other materials. This not only reduces the amount of raw materials needed but also decreases transportation costs and fuel consumption during construction. Lastly, steel is highly versatile and can be used in a wide range of applications, from construction to manufacturing. This versatility allows for the creation of innovative and sustainable designs that optimize energy efficiency and reduce environmental impact. For example, steel angles can be used in the construction of energy-efficient buildings that incorporate renewable energy systems, reducing overall energy consumption and greenhouse gas emissions. Overall, the use of steel angles offers several environmental benefits, including reduced energy consumption, lower carbon emissions, decreased waste generation, and increased durability. These factors make steel angles a sustainable and environmentally-friendly choice for various applications.

- Q: What is the standard size of steel angles?

- Steel angles come in a range of sizes that vary depending on the region and industry standards. Generally, they are available in equal and unequal leg lengths, with the equal leg angles typically sized between 20mm and 200mm. The thickness of the angle can also vary, typically falling between 3mm and 20mm. However, it is crucial to understand that these measurements may differ based on the specific application or project requirements. To determine the correct size of steel angles for a particular project, it is recommended to consult industry standards or manufacturers.

- Q: What are the different types of steel angles connections for columns?

- There are several different types of steel angle connections that can be used for columns in construction. 1. Bolted Angle Connection: This is a commonly used connection where steel angles are bolted together to form a joint. The angles are usually attached to the column using bolts and plates, providing a strong and reliable connection. 2. Welded Angle Connection: In this type of connection, the steel angles are welded directly to the column. Welded connections offer excellent strength and stiffness, making them suitable for heavy-duty applications. 3. Gusset Plate Connection: A gusset plate is a flat plate that is attached to the column and the steel angles to form a connection. The gusset plate is usually bolted or welded to provide additional strength and stability. 4. Cleat Connection: A cleat is a small piece of steel that is bolted or welded to the column and the steel angles. Cleat connections are commonly used for smaller columns and provide a simple and cost-effective solution. 5. Moment Connection: A moment connection is designed to resist both axial and bending loads. It involves welding or bolting steel angles to the column, along with additional reinforcing plates and stiffeners to provide the required strength and rigidity. 6. Eccentric Connection: An eccentric connection is used when the load is applied off-center to the column. It involves attaching the steel angles to the column at an offset position to account for the eccentric load. Overall, the choice of steel angle connection for columns depends on factors such as the load requirements, structural design, and construction methods. It is important to consider the specific needs of the project and consult with a structural engineer to determine the most appropriate connection type.

Send your message to us

Hot Rolled Steel Equal Angle High Quality

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords