Hot Rolled Steel Coils,Hot Rolled Steel Plates Thickness 5.0

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 28 m.t.

- Supply Capability:

- 200000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

DESCRIPTION FOR SS400 CARBON STEEL SHEET

1.Thickness: 1-200mm

2.Width: 100-3000mm

3.Length: 1000-12000mm

4. Applications :mining machinery, environmental protection, engineering

5. Grade:SS400 A 36 Q195.Q235.Q345.SPCC.SPCH

6.Surface : Hot Rolled Cold Rolled Galvanized Steel

DESCRIPTION FOR CARBON STEEL PLATE

Product | carbon steel plate price per ton |

Place of origin | Tianjin,China mainland |

MOQ | 25 tons |

Thickness | 1mm-200mm |

Width | 1000mm-3000mm |

Length | 1000mm-2000mm |

Application | widely |

Standard | AISI,ASTM,BS,DIN,JIS,GB,etc |

Grade | A572,A573,A633,A678,A709,A710,G3101,G3136,etc |

Tpye | Steel plate |

Surfacing | Coated |

Productive Technology | Hot Rolled & Cold Rolled |

Price | FOB USD 500-900 per ton |

Port | TIANJIN,SHANGHAI |

Payment Terms | L/C,T/T,Western Union,MoneyGram |

Product Ability | 1000 tons per month |

Delivery | 10 days after deposit or according to customers' quantity |

Packing | standard seaworthy export packing or as the request of customers |

FEATURES OF STEEL COILS

(1)Good ductility

(2)Good corrosion resistance

(3)Excellent abrasion resistance and fatigue strength

(4)Good weldability

(5)Oxidation resistant performance

(6)Excellent in high temperature

PACKING:

1.Big thickness:by bulk vessel

2.Small thickness:packed by steel strips and shipped by container

3.According to the requirements of customers'

TRADE TERMS :FOB, CFR, CIF

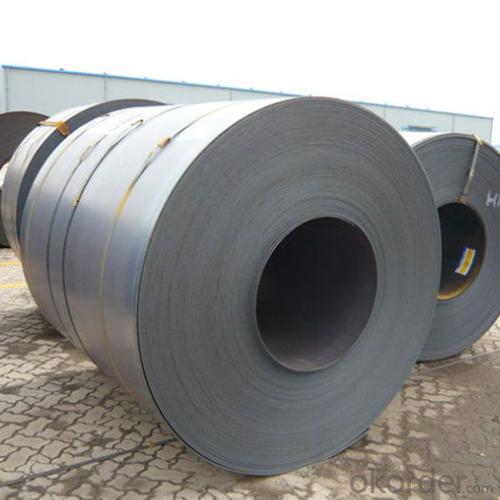

DETAILED PICTURES FOR STEEL COILS

FAQ:

Q:You are Factory or Trading Company?

A:We are factory,our main products include Steel plate,Steel Bar,Steel coils.

Q:What’s the MOQ?

A:Generally,the trail order will be accepted.The MOQ can be confirmed according to the different products.For example,the MOQ of rebar will be 25-50MT,the galvanized steel pipe will be 10MT,the stainless steel pipe will 1-5MT.

- Q: Are stainless steel sheets suitable for heat transfer equipment?

- Stainless steel sheets are indeed a suitable option for heat transfer equipment. The reason lies in the remarkable thermal conductivity properties of stainless steel, enabling it to effectively transfer heat between different mediums. Its ability to endure high temperatures without warping or deforming makes it particularly well-suited for heat transfer applications. Moreover, stainless steel's resistance to corrosion guarantees the equipment's durability and longevity. Additionally, its hygienic qualities make it a fitting choice for industries such as food and pharmaceuticals, where cleanliness is of utmost importance. In conclusion, stainless steel sheets are a dependable and efficient selection for heat transfer equipment.

- Q: Do stainless steel sheets require any special handling or storage?

- Yes, stainless steel sheets do require special handling and storage. They should be stored in a clean, dry, and well-ventilated area to prevent corrosion. It is important to handle them with clean gloves or tools to avoid contamination. Additionally, they should be protected from scratches or dents during transportation and storage to maintain their quality.

- Q: How do I prevent fingerprints or smudges on stainless steel sheets?

- To avoid the presence of fingerprints or smudges on stainless steel sheets, there are several simple steps that can be taken: 1. Regularly clean the surface: Regularly wiping the stainless steel sheets with a soft cloth or microfiber cloth can help prevent the accumulation of fingerprints and smudges. 2. Utilize mild soap and water: Create a mixture of warm water and a few drops of mild dish soap. Dip the cloth into this solution and gently wipe the stainless steel surface in the direction of the grain. This will eliminate any dirt or oil that may attract fingerprints. 3. Thoroughly dry: After cleaning, ensure that the stainless steel sheets are completely dry by using a clean, dry cloth. This will prevent the occurrence of water spots or streaks that can give the surface a smudged appearance. 4. Avoid abrasive cleaning agents or tools: Refrain from using harsh chemicals, abrasive cleaners, or scrub brushes as they can harm the stainless steel finish, making it more susceptible to smudges and fingerprints. Stick to mild cleaning solutions and soft cloths in order to preserve the integrity of the surface. 5. Apply a stainless steel cleaner or polish: Applying a stainless steel cleaner or polish can establish a protective barrier on the surface, rendering it more resistant to fingerprints and smudges. Adhere to the instructions provided with the product and use a clean cloth, following the grain of the stainless steel. 6. Use gloves: If you are aware that your hands tend to leave fingerprints easily, it may be beneficial to wear gloves while handling stainless steel sheets. This precautionary measure can prevent direct contact with the surface and diminish the likelihood of leaving smudges. By adhering to these suggestions, the cleanliness and luster of your stainless steel sheets can be maintained, thereby preventing fingerprints and smudges from diminishing their appearance.

- Q: Are stainless steel sheets suitable for water treatment facilities?

- Indeed, water treatment facilities find stainless steel sheets to be highly suitable. Known for its corrosion resistance, stainless steel proves to be essential in an environment where water and chemicals are consistently present. It effectively resists rust and degradation, guaranteeing the longevity and durability of the sheets. Moreover, stainless steel boasts ease of cleaning and maintenance, rendering it an ideal choice for facilities that necessitate regular hygiene and sanitation. Furthermore, this material exhibits remarkable resistance to heat and extreme temperatures, ensuring its performance even in demanding conditions. Additionally, stainless steel is non-reactive, meaning it does not release any harmful substances into the water during treatment processes. Consequently, it stands as a safe and reliable option for water treatment applications.

- Q: How do you remove fingerprints from brushed stainless steel sheets?

- To remove fingerprints from brushed stainless steel sheets, you can follow these simple steps: 1. Start by gathering the necessary cleaning supplies. You will need a microfiber cloth, mild dish soap, warm water, and a stainless steel cleaner or vinegar. 2. Begin by dampening the microfiber cloth with warm water. Make sure the cloth is not soaking wet, just slightly damp. 3. Gently wipe the stainless steel surface in the direction of the grain. It is important to always follow the grain to avoid causing scratches or streaks. 4. If the fingerprints persist, you can add a small amount of mild dish soap to the damp cloth and continue wiping the surface. Be sure to rinse the cloth thoroughly after applying the soap. 5. If the fingerprints are still visible, you can use a stainless steel cleaner specifically designed for brushed stainless steel surfaces. Apply a small amount of the cleaner onto the microfiber cloth and wipe the surface in the direction of the grain. Remember to follow the manufacturer's instructions for the specific cleaner you are using. 6. Alternatively, you can use white vinegar as a natural cleaning solution. Dampen a cloth with vinegar and gently wipe the surface in the direction of the grain. Vinegar can help remove fingerprints and restore shine. 7. Once you have removed the fingerprints, use a dry microfiber cloth to buff the surface gently. This will help remove any remaining streaks and give the stainless steel a polished finish. Remember to always test any cleaning solution on a small, inconspicuous area of the stainless steel sheet before applying it to the entire surface. Additionally, avoid using abrasive materials or cleaners that contain chlorine or bleach, as they can damage the brushed finish of the stainless steel.

- Q: Can stainless steel sheets be used for railway station facades?

- Railway station facades can indeed utilize stainless steel sheets. These sheets are made from a resilient and corrosion-resistant material, capable of enduring severe weather conditions. As a result, they are well-suited for outdoor applications. Moreover, stainless steel boasts an appealing and contemporary look, making it highly favored in architectural design. Its ease of cleaning and maintenance is also noteworthy, particularly in heavily trafficked zones such as railway stations. All in all, stainless steel sheets prove to be a fitting and pragmatic choice for railway station facades.

- Q: What is the thickness range for stainless steel sheets?

- The thickness range for stainless steel sheets can vary depending on the specific grade and application. Generally, stainless steel sheets are available in thicknesses ranging from 0.4mm to 6mm. However, for specialized applications, thinner or thicker sheets may be required. It is important to consult with a supplier or refer to industry standards to determine the appropriate thickness range for a specific project or application.

- Q: What are the common sizes and thicknesses available for stainless steel sheets?

- Common sizes for stainless steel sheets range from 4 feet by 8 feet to 5 feet by 10 feet, although custom sizes can also be produced. The thicknesses typically vary from 0.4mm to 6mm, with the most commonly used thicknesses being 0.8mm, 1mm, 1.2mm, and 1.5mm.

- Q: What are the different types of stainless steel sheets available?

- There are several different types of stainless steel sheets available, including austenitic, ferritic, martensitic, duplex, and precipitation-hardening stainless steel sheets. Each type has its own unique properties and characteristics, making them suitable for various applications in industries such as construction, automotive, and food processing.

- Q: What is the process of stainless steel mirror panel? What's the difference between them and stainless steel sand blasting plates?

- The 8K board, also called mirror panel, is polished on the surface of stainless steel by grinding fluid through polishing equipment, so that the surface of the plate is as clear as the mirror. Uses: mainly used in architectural decoration, elevator decoration, industrial decoration, facilities, decoration and other stainless steel products.

Send your message to us

Hot Rolled Steel Coils,Hot Rolled Steel Plates Thickness 5.0

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 28 m.t.

- Supply Capability:

- 200000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords