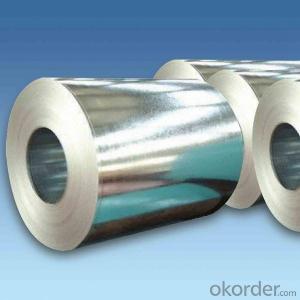

Hot Rolled Stainless Steel Coils 304L Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Products Description

Name: stainless steel coils/plates/sheets

Discharge Port: Any Port, China

Cold Rolled Size: thickness0.3-8mm,Width:280-2100mm

Hot Rolled Size: Thickness3-14mm,Width:650-2100mm

Hot Rolled/Cold Rolled Plates : Thickness2-80mm,Width:1500-3000mm

Coil Weight: About 20 Tons

Grade: 201,202,304/304L/304H, 316/316L/316H, 409/L,430 etc.

Technique: Hot Rolled/Cold Rolled

Finish:2B, BA, 2D, No1, No2 etc

Edge: Mill Edge / Slitting Edge

Packaging: In bundles, or as customer's requirement

Place of Origin: Made in China

MOQ: 20 Tons

Payment Terms: 100% LC at sight, or 100%TT in advance

Delivery Time: With 30-40 days after deposit

Pictures:

Application

Boiler heat exchanger, machinery andpetroleum ,chemical industries, hardware fields,Food industry,construction material,kitchen utensils, building construction, medical equipment,chemical tank, pipe etc

Export Markets

Our target market is the international market. Every year we export most of products to countries like India, Pakistan, South Korea, Brazil, Australia, South Africa, Spain, Sri Lanka, Taiwan, Hong Kong, etc.

- Q: What's the difference between stainless steel 8K and BA?. How to distinguish from the surface of materials?

- The 304430 BA of stainless steel can achieve the effect of 6K or 8K. Is the most direct Kanban lines then some words to be processed is certainly not 8K, BA is 8K achieve brightness over direct annealing processing completely invisible plate lines in acid corrosion in the grinding process has damage the surface of the protective layer.

- Q: What are the common uses of stainless steel sheets in the food industry?

- Stainless steel sheets are widely used in the food industry due to their numerous beneficial properties. One common use of stainless steel sheets in the food industry is for food processing equipment. These sheets are used to fabricate machines such as mixing tanks, conveyors, and food processing tables. Stainless steel sheets are preferred for this purpose because they are resistant to corrosion, easy to clean, and do not react with food substances, ensuring the food's safety and hygiene. Another common use of stainless steel sheets in the food industry is for food storage and transportation. Stainless steel sheets are often used to manufacture containers, tanks, and barrels that are used to store and transport food products. The corrosion resistance of stainless steel ensures that the food is protected from contamination and spoilage during storage and transportation. Stainless steel sheets are also used for kitchen equipment in the food industry. Countertops, sinks, and cabinets are frequently made from stainless steel sheets due to their durability, heat resistance, and ease of cleaning. These qualities make stainless steel sheets ideal for use in food preparation areas where hygiene is of utmost importance. Furthermore, stainless steel sheets are utilized in the construction of food service equipment such as ovens, grills, and refrigerators. These sheets are crucial in maintaining the desired temperature and preventing the growth of bacteria, ensuring that the food served is safe and of high quality. In summary, stainless steel sheets are commonly used in the food industry for food processing equipment, food storage and transportation, kitchen equipment, and food service equipment. Their corrosion resistance, easy maintenance, and ability to uphold hygiene standards make them an ideal choice for various applications in the food industry.

- Q: What is the price range of stainless steel sheets?

- The price of stainless steel sheets can fluctuate due to a variety of factors, including the grade, sheet thickness, size, and any additional finishes or coatings. Typically, the price range for stainless steel sheets begins at approximately $20 per sheet for smaller sizes and standard grades. However, for larger sizes, higher grades, and specialized finishes, the price can escalate to several hundred dollars per sheet. It is worth mentioning that prices can also differ depending on the supplier and market conditions. Therefore, it is advisable to compare prices from multiple sources in order to secure the most favorable deal.

- Q: What do stainless steel 304 industrial surfaces refer to?

- The industrial surface is the ordinary pickling surface, which is treated by the last pickling process. It's the white surface we usually see. The bright surface that we see in our lives is a surface that has been further polished or annealed.

- Q: Are stainless steel sheets suitable for water treatment facilities?

- Yes, stainless steel sheets are highly suitable for water treatment facilities. Stainless steel is known for its corrosion resistance, which is crucial in an environment where water and chemicals are constantly present. It is resistant to rust and degradation, ensuring the longevity and durability of the sheets. Additionally, stainless steel is easy to clean and maintain, making it an ideal choice for facilities that require regular hygiene and sanitation. The material is also highly resistant to heat and extreme temperatures, ensuring its performance even in demanding conditions. Moreover, stainless steel is non-reactive, meaning it does not release harmful substances into the water during treatment processes, making it safe and reliable for water treatment applications.

- Q: What are the different grades of stainless steel sheets?

- There are several different grades of stainless steel sheets, including 304, 316, 430, and 201.

- Q: Can stainless steel sheets be formed into complex shapes?

- Yes, stainless steel sheets can be formed into complex shapes. Stainless steel is known for its excellent formability and versatility, making it one of the most widely used materials in various industries. It can be easily fabricated using techniques such as bending, rolling, stamping, and deep drawing, allowing the formation of complex shapes with precision and accuracy. Moreover, stainless steel has high ductility and can withstand significant deformation without losing its mechanical properties or structural integrity. As a result, it is often preferred for applications that require intricate and customized designs, such as architectural structures, automotive parts, kitchen appliances, and medical equipment.

- Q: What's the difference between 201 and 204 stainless steel plates? Thank you

- The price is different: 01 cheaper, 04 expensive. Toughness is different: 01 hardness, 04 toughness.

- Q: Can stainless steel sheets be used for medical implant devices?

- Yes, stainless steel sheets can be used for medical implant devices. Stainless steel is a widely used material in the medical industry due to its excellent mechanical properties, corrosion resistance, and biocompatibility. It is known for its strength, durability, and ability to withstand sterilization processes. Stainless steel sheets can be fabricated into various medical implant devices such as plates, screws, and pins used in orthopedic surgeries, dental implants, cardiovascular devices, and many others. The high strength-to-weight ratio of stainless steel makes it suitable for load-bearing applications, while its resistance to corrosion ensures longevity within the body. Furthermore, stainless steel is a biocompatible material, which means it is well-tolerated by the human body and does not cause adverse reactions or allergies. The surface of stainless steel can be modified to enhance its biocompatibility by processes like passivation or coating. It is important to note that the selection of the appropriate stainless steel grade and surface finish is crucial for medical implant devices to ensure compatibility with the specific body tissue and environment. Additionally, thorough testing and regulatory approval are required to ensure the safety and efficacy of stainless steel medical implant devices. In conclusion, stainless steel sheets can indeed be used for medical implant devices due to their mechanical properties, corrosion resistance, and biocompatibility. Proper selection, testing, and regulatory approval are essential to ensure the suitability and safety of stainless steel implants in medical applications.

- Q: What brand of stainless steel plate is good?

- Stainless steel plate has a smooth surface, high plasticity, toughness and mechanical strength, corrosion of acid, alkaline gas, solution and other medium.

Send your message to us

Hot Rolled Stainless Steel Coils 304L Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords