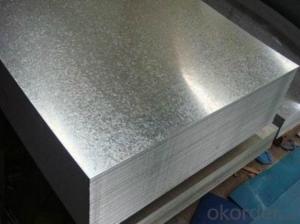

Best Quality for Regular Spangle Hot Dipped Galvanized Steel Sheet

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50mt m.t.

- Supply Capability:

- 10000 tons per month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information of Hot Dip Galvanized Steel Coil

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial applications.

Specification of Hot Dip Galvanized Steel Coil:

1. Thickness: 0.13mm-0.7mm

2. Width: 600mm-1250mm

3. Zinc Coating: 30-200g/m2

4. Internal Diameter: 508mm/610mm

5. Coil Weight: 3-12MT

6. Quality: commercial and structural quality

7. Surface Treatment: regular & minimum spangle, zero spangle, oiled & dry , chromated , non-skin pass ,skin pass

8. Standard: JIS G 3302, ASTM A 653M, EN 10327

9. Steel Grade: SGCC, CS, FS, SS, LFQ, DX51D+Z , S280GD

Technical Data of Hot Dip Galvanized Steel Coil

Chemical Composition | C | Si | Mn | P | S |

0.04-0.06% | 0.01-0.03% | 0.18-0.22% | 0.014-0.016% | 0.006%-0.009% |

Technical Data | |

Yield Strength | (Mpa) 280-320 |

Tensile Strength | (Mpa) 340-390 |

Elongation | 20%-30% |

Out-of-square | not exceed 1% Flatness |

Bow | 15mmmax |

Edge Wave | 9mmmax |

Centre Buckle | 8mmmax |

Bending At 180 Degree | No crack, purling and fraction |

Application of Hot Dip Galvanized Steel Coil

It can be widely used in transportation, light industry, civil usage and farming. It is also the perfect building material in construction for making roofing tile, steel profiles for wall partition, T-bar, studs, fireproof door, air conditioning duct and home appliance.

Package of Hot Dip Galvanized Steel Coil

Full wrapped with anti-damped paper inside, iron sheet wrapped outside, and bundled by iron strips.

- Q: How is steel produced?

- Steel is primarily produced through a process called basic oxygen steelmaking, where iron ore is converted into liquid iron and then further refined by removing impurities and adding alloying elements to achieve desired properties. This is done by combining iron ore, limestone, and coke in a blast furnace, followed by a refining process using oxygen to remove impurities and adjust the carbon content. The resulting molten iron is then poured into molds, solidified, and processed into various forms of steel.

- Q: What are the different types of steel rods and their applications?

- There are several types of steel rods commonly used in construction and manufacturing. Some common types include mild steel rods, stainless steel rods, carbon steel rods, and alloy steel rods. Mild steel rods are widely used due to their affordability and versatility. They are commonly used in general construction, reinforcement of concrete structures, and fabrication of fences and gates. Stainless steel rods offer excellent corrosion resistance and are used in applications where hygiene and aesthetic appeal are important, such as in food processing, pharmaceuticals, and marine environments. Carbon steel rods are known for their high strength and durability. They are commonly used in heavy-duty construction projects, such as bridges, high-rise buildings, and infrastructure. Alloy steel rods are made from a combination of different metals, offering specific properties such as increased strength, hardness, and resistance to wear and tear. They are often used in applications that require high performance, such as automotive parts, machinery, and tooling. Overall, the choice of steel rod depends on the specific requirements of the application, considering factors such as strength, corrosion resistance, cost, and environmental conditions.

- Q: How is steel used in the manufacturing of water treatment systems?

- Steel is commonly used in the manufacturing of water treatment systems due to its durability and corrosion resistance. It is used to construct various components of these systems such as tanks, pipes, and frames. Steel ensures the structural integrity of the system and helps in withstanding the harsh conditions often found in water treatment processes.

- Q: How do steel products contribute to the healthcare and medical industry?

- Steel products contribute to the healthcare and medical industry in various ways. Firstly, stainless steel is widely used in the production of medical equipment and surgical instruments due to its durability, corrosion resistance, and ease of sterilization. From scalpels and forceps to prosthetics and implants, steel ensures the reliability and hygiene of these critical tools. Additionally, steel is used in the construction of healthcare facilities, providing strength, stability, and fire resistance. Furthermore, steel is also used in medical storage systems such as cabinets and shelves, ensuring efficient organization and safety of medical supplies. Overall, steel products play a vital role in maintaining the quality, safety, and functionality of healthcare and medical services.

- Q: How does steel pipe coating for underground applications work?

- Steel pipe coating for underground applications works by applying a protective layer to the pipe's surface. This coating acts as a barrier against corrosion, abrasion, and chemical damage, ensuring the longevity and integrity of the pipe in underground environments. The coating process typically involves cleaning and prepping the pipe's surface, followed by the application of a primer and a topcoat. The primer enhances adhesion and corrosion resistance, while the topcoat provides additional protection and durability. Coating methods can vary, including fusion bonded epoxy, polyethylene, or polyurethane, depending on the specific application requirements.

- Q: What are the common uses of steel products in construction?

- Steel products are commonly used in construction for various purposes such as structural support, reinforcement, framing, and fabrication of beams, columns, and trusses. Steel is also used for roofing, cladding, and siding due to its durability, strength, and resistance to fire and weather conditions. Additionally, steel is utilized for the construction of bridges, highways, and other infrastructure projects, as well as for the production of doors, windows, and fixtures.

- Q: How is steel used in the construction of convention centers and exhibition halls?

- Steel is commonly used in the construction of convention centers and exhibition halls for its strength and durability. It is used to create the structural framework of the buildings, including pillars, beams, and trusses, providing support and stability. Steel is also used in the construction of roofing systems, walls, and facades, ensuring the overall integrity of the structure. Additionally, steel can be easily fabricated and allows for flexible and large-scale designs, making it an ideal material for constructing spacious and versatile event spaces.

- Q: What are the different types of steel bolts and their uses?

- There are various types of steel bolts, each designed for specific applications. Some common types include hex bolts, carriage bolts, anchor bolts, and eye bolts. Hex bolts are the most versatile and widely used, typically for general fastening purposes. Carriage bolts have a round head and are commonly used in wood-to-wood connections. Anchor bolts are used to secure structures to concrete or masonry. Eye bolts have a looped head and are ideal for lifting heavy objects. The choice of bolt depends on the specific requirements of the project and the type of materials being fastened.

- Q: How is steel used in the production of railway tracks?

- Steel is used in the production of railway tracks due to its durability, strength, and resistance to wear and tear. It is used to create the rails that form the tracks, providing a sturdy and reliable surface for trains to run on. Steel also allows for efficient and smooth travel, as its properties enable trains to move swiftly and safely along the tracks.

- Q: What are the properties of abrasion-resistant steel for industrial equipment?

- Abrasion-resistant steel for industrial equipment possesses several key properties. Firstly, it has a high hardness level which enables it to withstand the constant wear and tear caused by abrasive materials. Additionally, this type of steel exhibits excellent toughness and impact resistance, making it highly durable in harsh working conditions. It also has a low coefficient of friction, reducing the likelihood of material sticking to the surface. Moreover, abrasion-resistant steel offers good weldability, allowing for easy fabrication and repair of equipment. Overall, these properties make it an ideal choice for industrial applications where equipment is exposed to abrasive substances.

1. Manufacturer Overview

| Location | Zhejiang, China |

| Year Established | 1999 |

| Annual Output Value | US$1 Million - US$2.5 Million |

| Main Markets | Europe; Africa; Mid East; Southeast Asia |

| Company Certifications | ISO9001;ISO14001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai Port |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 50-80 |

| Language Spoken: | Chinese, English |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | 5 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average |

Send your message to us

Best Quality for Regular Spangle Hot Dipped Galvanized Steel Sheet

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50mt m.t.

- Supply Capability:

- 10000 tons per month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords