Hot Rolled Band Steel In Coil Corrugated Steel Band With Competitive Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Hot Rolled Band Steel In Coil Corrugated Steel Band With Competitive Price at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Hot Rolled Band Steel In Coil Corrugated Steel Band With Competitive Price are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Hot Rolled Band Steel In Coil Corrugated Steel Band With Competitive Price are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Corresponding Steel Grade for Reference:

CHN, GB | JPN, JIS | GER, DIN |

50CrVA | SUP10 | 50CrV4 |

GBR, BS | FRA,FN | |

735A51 | 50CV4 |

Chemical Composition:

C | Si | Mn |

0.46~0.54 | 0.17~0.37 | 0.50~0.80 |

S | P | Cr |

≤0.030 | ≤0.030 | 0.80~1.10 |

Ni | Cu | V |

≤0.35 | ≤0.25 | 0.10~0.20 |

Mechanical Properties:

-Tensile Strength σb (MPa): ≥1274 (130)

-Yield Strength σs (MPa): ≥1127 (115)

-Elongation δ5 (%):≥10

-Percentage reduction of area: ψ (%): ≥40

-Hardness:

1, Hot rolled, ≤321HB

2, Cold drawn + Heat treatment: ≤321HB

-Norm of heat treatment:

1, Quenching: 850℃±20℃.

2, Cooled by oil.

3, Tempering: 500℃±50℃.

Usage/Applications

Mechanical Properties are good. 50CrVA have high hardenability. The element V reduces thermal sensitivity and improves the strength and toughness. The fatigue strength and yield point are high but the weld ability is bad.

-50CrVA is a nice material of spring. Usually it’s used as valve spring, piston spring and secure valve spring with big section that can bear much load. The working temperature is below 300℃

Packaging & Delivery

-Packing Detail: The products will be well packed.

-Delivery Detail: 30~45 working days after receive buyer’s T.T. or L/C.

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q4: What makes stainless steel stainless?

A4: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

Q5: Can stainless steel rust?

A5: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

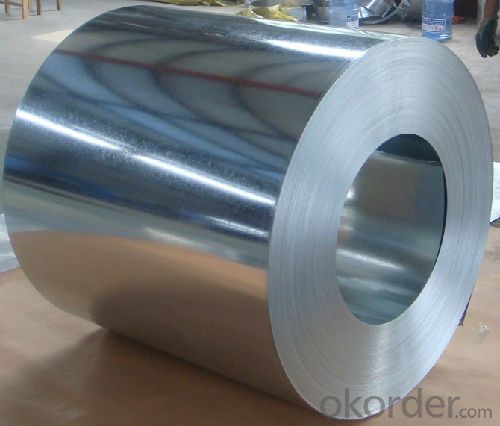

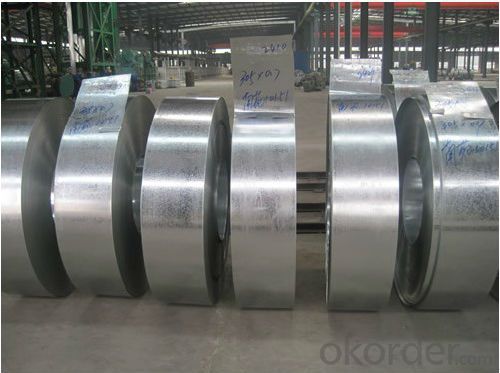

Images:

- Q: What are the applications of steel angles?

- Steel angles have a wide range of applications in construction and manufacturing industries. Some common uses include providing structural support in buildings and bridges, reinforcing concrete structures, creating frameworks for machinery and equipment, as well as forming braces and brackets for various architectural and engineering projects.

- Q: How is steel bar reinforcement used in concrete structures?

- Steel bar reinforcement is used in concrete structures to enhance their strength and durability. The steel bars, also known as rebars, are embedded within the concrete to provide resistance against tension and prevent cracking. This reinforcement technique helps the concrete withstand various forces, such as bending, shearing, and compression, ultimately increasing its load-bearing capacity and structural integrity.

- Q: How are steel products used in the aerospace industry?

- Steel products are used in the aerospace industry for various purposes, including the construction of aircraft structures, engine components, and landing gear. Steel's strength, durability, and high temperature resistance make it an ideal material for these critical applications, ensuring the safety and reliability of aerospace vehicles.

- Q: What are the different types of steel sheet and their uses?

- There are several types of steel sheets available, each with distinct properties and uses. Some common types include hot-rolled steel, cold-rolled steel, galvanized steel, and stainless steel. Hot-rolled steel sheets are often used in construction and manufacturing due to their strength and durability. Cold-rolled steel sheets, on the other hand, are smoother and have tighter tolerances, making them suitable for applications requiring precise dimensions. Galvanized steel sheets have a protective zinc coating, making them resistant to corrosion, and are commonly used in outdoor structures or for automotive parts. Stainless steel sheets are known for their resistance to corrosion and high temperature, making them ideal for applications in food processing, medical equipment, and chemical industries. Overall, the choice of steel sheet type depends on the specific requirements and intended use of the product.

- Q: What is the process of galvanizing steel?

- The process of galvanizing steel involves immersing the steel into a bath of molten zinc, which creates a protective coating on its surface. This coating helps prevent corrosion and extends the lifespan of the steel. The steel is first cleaned to remove any impurities, then it is dipped into the zinc bath. The zinc coating bonds with the steel through a metallurgical reaction, forming a strong and durable protective layer. After the galvanizing process, the steel is cooled and can be further treated or fabricated for various applications.

- Q: How are steel gratings used in industrial flooring?

- Steel gratings are commonly used in industrial flooring as they provide a strong and durable surface for workers to walk on. They are designed with an open grid pattern that allows for efficient drainage of liquids and debris, making them ideal for environments where spills or moisture are common. Additionally, steel gratings offer excellent traction and can withstand heavy loads, making them suitable for areas with heavy machinery or equipment. Overall, steel gratings enhance safety and efficiency in industrial settings by providing a reliable and slip-resistant flooring solution.

- Q: What are the challenges faced in the welding of steel products?

- Some of the challenges faced in the welding of steel products include achieving proper weld penetration, ensuring proper heat distribution, managing distortion and warping, dealing with welding fumes and safety hazards, and maintaining weld quality and integrity.

- Q: What are the different types of steel profiles and sections available?

- There are various types of steel profiles and sections available, including I-beams, H-beams, U-channels, angles, square and rectangular tubes, round bars, and flat bars. These profiles and sections have different shapes and dimensions, allowing them to be used for various structural and construction purposes.

- Q: How is steel used in the production of machinery and equipment?

- Steel is used in the production of machinery and equipment due to its exceptional strength, durability, and versatility. It is commonly used for manufacturing machine frames, gears, shafts, and various components that require high strength and resistance to wear and tear. The use of steel ensures the machinery and equipment can withstand heavy loads and harsh operating conditions, ultimately enhancing their performance and longevity.

- Q: How is steel used in the construction of underground utilities?

- Steel is commonly used in the construction of underground utilities due to its durability and strength. It is used in the form of pipes, conduits, and casings to house and protect various utility systems such as water, gas, and electrical lines. Steel's resistance to corrosion and its ability to withstand high pressure and heavy loads make it a reliable choice for underground infrastructure, ensuring the safe and efficient delivery of essential services.

Send your message to us

Hot Rolled Band Steel In Coil Corrugated Steel Band With Competitive Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords