Manufacturer of Glue Steel Fiber

- Loading Port:

- Guangzhou Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 50000000 Ton Per Year m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

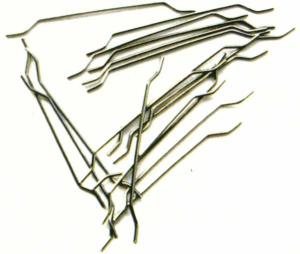

Introduction of Glue Steel Fiber:

The Glue Steel Fiber uses high-quality low-carbon steel wire, they are high-performance steel fiber, with the characteristics of the high tensile strength, good toughness, etc. The product is widely welcomed by our clients all over the world. The professional service and good quality has won high reputation all over the world. The Glue Steel Fiber could avoid the fiber tangle get together, it is more smooth when mixed.

Data Sheet of Glue Steel Fiber:

DIA (mm) | Length (mm) | Tensile Strength (MP) |

1 | 60 | ≥1000 |

1 | 50 | ≥1000 |

0.9 | 60 | ≥1000 |

0.9 | 50 | ≥1000 |

0.75 | 60 | ≥1000 |

0.75 | 45 | ≥1000 |

0.75 | 35 | ≥1000 |

0.55 | 30 | ≥1000 |

0.5 | 30 | ≥1000 |

0.5 | 25 | ≥1000 |

0.4 | 25 | ≥1000 |

Application of glue steel fiber:

Primary dispersion: Direct adding steel fibers to the belt, the rows of steel fiber as a whole, each of the concrete uniformly dispersed

Corner

Secondary dispersion: a water-soluble glue starts to dissolve, in a row of steel fibers in a dispersion premise, dispersed again in every corner of the monofilament fiber, showing a perspective view in the concrete of the fiber web, which play the role of an overall reinforcement .

- Q: What are the different types of steel bars?

- There are several different types of steel bars, including mild steel bars, deformed steel bars, stainless steel bars, and alloy steel bars.

- Q: How is steel wire rope used in elevators?

- Steel wire rope is used in elevators to provide the necessary strength and durability to support the weight of the elevator car and passengers. It is used as the primary load-bearing component, connecting the elevator car to the counterweight system and the hoisting machinery. This wire rope is designed to withstand high tensile forces and is crucial for ensuring safe and reliable vertical transportation in elevators.

- Q: How do steel products contribute to the transportation and logistics sector?

- Steel products play a significant role in the transportation and logistics sector by providing strength, durability, and versatility. Steel is commonly used in the construction of vehicles, such as cars, trucks, trains, ships, and airplanes, due to its high tensile strength and impact resistance. It ensures the safety and reliability of these vehicles, enabling them to carry heavier loads and withstand harsh environmental conditions. Additionally, steel is used in the infrastructure of transportation systems, including bridges, railways, and ports, ensuring their stability and longevity. Overall, steel products are essential for enhancing the efficiency, safety, and sustainability of the transportation and logistics sector.

- Q: How is steel wire used in the production of cables?

- Steel wire is commonly used in the production of cables as a core strength component. It provides the necessary strength and durability to withstand tension and bending forces, ensuring the cable can support heavy loads and resist breakage. Additionally, steel wire can enhance the overall flexibility and stability of the cable, allowing it to be easily installed and remain in place even under challenging conditions.

- Q: How are steel products used in the construction of government buildings and administrative centers?

- Steel products are extensively used in the construction of government buildings and administrative centers due to their durability, strength, and versatility. These products offer structural support, allowing for the construction of large and complex buildings. Steel beams, columns, and frames are commonly used to provide stability and withstand heavy loads. Additionally, steel is used for roofing, cladding, and interior partitioning, providing fire resistance and enhancing the overall safety of the structure. The use of steel products in government buildings ensures longevity, cost-effectiveness, and compliance with stringent safety regulations.

- Q: How is steel forgings inspected for quality assurance?

- Steel forgings are inspected for quality assurance through a combination of visual examination, non-destructive testing, and mechanical testing. Visual inspection involves checking for surface defects such as cracks, porosity, or irregularities in shape. Non-destructive testing methods, such as ultrasonic or magnetic particle testing, are used to detect internal defects that may not be visible. Mechanical testing involves subjecting the forgings to various load tests to ensure they meet specified strength and hardness requirements. These inspection techniques help ensure the quality and integrity of steel forgings before they are used in various applications.

- Q: How do steel products contribute to the agriculture and farming sector?

- Steel products contribute to the agriculture and farming sector in various ways. For instance, steel is widely used in the construction of farm buildings, such as barns and storage facilities, providing durable and long-lasting structures to house livestock, equipment, and crops. Additionally, steel is utilized in manufacturing machinery and equipment used in farming operations, including tractors, plows, harvesters, and irrigation systems, making these tools more robust and efficient. Furthermore, steel is instrumental in the production of fencing materials, aiding in the establishment of secure boundaries and enclosures for livestock. Overall, steel products enhance the productivity, safety, and sustainability of the agricultural industry.

- Q: What are the different types of steel wires and their uses?

- There are several types of steel wires with various uses. Some common types include carbon steel wire, stainless steel wire, galvanized steel wire, and spring steel wire. Carbon steel wire is widely used for general purposes, such as in construction, fencing, and automotive applications. Stainless steel wire is corrosion resistant and commonly used in industries like food processing, medical equipment, and marine applications. Galvanized steel wire is coated with zinc to prevent rust and is often used for outdoor applications like fencing and electrical wiring. Spring steel wire is known for its elasticity and is used in manufacturing springs, suspension systems, and various mechanical components.

- Q: What are the uses of steel mesh in construction?

- Steel mesh is widely used in construction for various purposes. It is primarily used as reinforcement in concrete structures to improve their strength and durability. Steel mesh provides reinforcement by distributing the load across a larger area and preventing cracks from forming in the concrete. Additionally, it helps to control shrinkage and thermal expansion, enhancing the overall stability of the structure. Steel mesh is also used for fencing and barriers, providing security and protection in construction sites and other areas. Overall, steel mesh plays a crucial role in construction by enhancing the structural integrity and safety of buildings and infrastructure.

- Q: How are steel sheets used in the manufacturing of industrial machinery?

- Steel sheets are used in the manufacturing of industrial machinery because of their high strength, durability, and versatility. They can be fabricated into various components such as frames, panels, and casings, providing structural support and protection. Steel sheets are also used for forming complex shapes through processes like bending, cutting, and welding. Additionally, they offer resistance to heat, corrosion, and wear, making them suitable for harsh industrial environments.

1. Manufacturer Overview

| Location | Hunan, China |

| Year Established | 1989 |

| Annual Output Value | Above US$ 10 Million |

| Main Markets | North America; South America; Eastern Europe; Southeast Asia; Africa; Oceania; Mid East; Eastern Asia; Western Europe; Central America; |

| Company Certifications | ISO 9001:2000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Guangzhou Port |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | Above 10 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | Above 20,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Design Service Offered; Buyer Label Offered |

| Product Price Range | High; Average |

Send your message to us

Manufacturer of Glue Steel Fiber

- Loading Port:

- Guangzhou Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 50000000 Ton Per Year m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords