Aluminum composite board,hot sell aluminium clad composite panel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Specifications

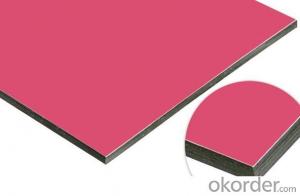

.Aluminum panels for walls aluminum composite panel

.Thickness: 4mm 6mm 8mm up to 20mm (only in Bolliya with special cladding profile)

.Aluminum Skin: AA1100, AA3003 AA3005 AA5052 optional

2. Description

| Paint: | PVDF, PE Or Others | |

| Skin Alloy: | 1100, 3003, 3005, 5005, 5052 | |

| Standard Thickness: | 4mm (details as below chart) | |

| Standard Size: | 1220*2440, 1500*4000 | |

| Coating Thickness: | >25UM (kynar, FEVE) >18um(PE), None for other metals | |

| Coating thickness | ECCA-T1[1995]Comply with customer standard | Kynar 500, 70%+ FC resin 28um + | ||

| Gloss Deviation | ECCA-T2[1995]30 (60 °) +/- 5 E | Gloss | 10% | |

| Colours Deviation | ECCA-T3[1995]ΔΕ≤0.8(CIE - L a b - system) | ΔE | 0.4-0.5 | |

| Pencil hardness | ECCA-T4[1995] ≥H | 2H | ||

| Impact resistance test | ECCA-T5[1995] 1 kg of weight falls from specified heigh | no detainting no cracking | ||

| T-Bending | ECCA-T7[1996] 0T Without severe cracks | 1T | ||

| Coating adhesive | not lower than class 1 | not lower than class 0 | ||

| MEK-test | ECCA-T11[1999] | Over 200 | ||

| Acid Resistance | 70% HNO3 30mins | ΔE< 5% | ||

| Boiling test | Bended sheets 1.0T after 5 minutes in boiling water | without cracks | ||

| Tensile Strenght | 155-180(Mpa) | ≥155 | ||

| Yield strength | ≥130Mpa) | ≥130 | ||

| Elongation | ≥3% | ≥3% | ||

| This test resulte is randomly tested by internal QC department and result in average datebase. | ||||

3. Application

Painting: Kynar 500 PVDF resin with quality dying material only from PPG or Beckers. 2-3 coating system as one of PPG's authorized coater in China. Color remain bright and vivid after long time duration even under server weathering considtion.

Using high-grade polyester lacquer coating material, the finished coated coils are with delicate color uniform texture, color and diverse. It is the most popular and most common used materials in decorative usage. The PE coated aluminum are widely used in ACP( aluminum composite panel ) production and indoor ceiling usage

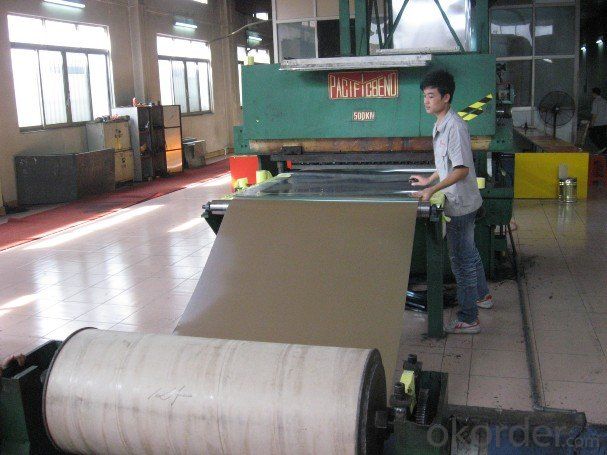

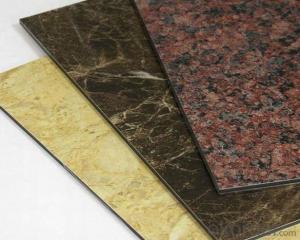

4. Pictures

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirement.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;

- Q: How do steel products contribute to the construction of theme-based amusement parks?

- Steel products play a crucial role in the construction of theme-based amusement parks by providing structural support, safety, and aesthetic appeal. Steel is widely used in the fabrication of roller coasters, water slides, and other thrill rides, ensuring their stability and durability. Additionally, steel frameworks and trusses are employed to construct large-scale structures such as theme park entrances, iconic landmarks, and indoor pavilions. The versatility and strength of steel enable designers to create intricate and gravity-defying structures, enhancing the overall experience and visual appeal of theme parks.

- Q: How is steel pipe threaded for plumbing applications?

- Steel pipe is threaded for plumbing applications using a process called threading, which involves cutting helical grooves or ridges on the external surface of the pipe. This is typically achieved using a threading machine or a die set. The threaded ends of the pipe can then be connected to fittings, allowing for a secure and leak-resistant plumbing system.

- Q: What are the properties of high-strength steel for structural applications?

- High-strength steel for structural applications possesses several key properties. Firstly, it has a significantly higher yield strength compared to conventional steel, allowing it to withstand higher loads and stresses without deforming permanently. Additionally, it exhibits excellent toughness and ductility, ensuring it can absorb energy and resist fracture even under extreme conditions. High-strength steel also offers improved corrosion resistance, reducing the risk of deterioration over time. Lastly, it has a relatively low weight-to-strength ratio, making it an ideal choice for lightweight and high-performance structures.

- Q: How is steel pipe coated for underground gas pipelines?

- Steel pipe for underground gas pipelines is typically coated using a three-layer coating system. The first layer is a fusion-bonded epoxy (FBE) primer that provides corrosion protection. The second layer is an adhesive that helps bond the FBE to the pipe. Finally, the third layer is a polyethylene or polypropylene coating that acts as a protective outer layer. This coating process ensures the steel pipe is well-protected against corrosion and other potential damages in underground environments.

- Q: How are steel pipes used in oil and gas pipelines?

- Steel pipes are used in oil and gas pipelines due to their strength, durability, and resistance to harsh conditions. These pipes are used to transport crude oil, natural gas, and other petroleum products over long distances. They are able to withstand high pressure and temperature variations, ensuring the safe and efficient transportation of these resources. Additionally, steel pipes are often coated with protective layers to prevent corrosion and ensure the longevity of the pipeline system.

- Q: What are the common uses of steel in the defense industry?

- Steel is commonly used in the defense industry for various purposes, including the production of military vehicles, aircraft carriers, submarines, and tanks. It is also utilized in the construction of bulletproof vests, helmets, and other protective gear. Additionally, steel is used in the manufacturing of weapons, such as firearms, artillery, and missiles, due to its strength and durability.

- Q: How is steel rebar used in concrete construction?

- Steel rebar is used in concrete construction to provide reinforcement and strength to the concrete structures. It is typically placed within the concrete forms before pouring, creating a framework that helps to increase the structural integrity and durability of the concrete. The steel rebar acts as a tension device, absorbing and distributing the forces that act upon the concrete, such as those caused by weight, temperature changes, and natural disasters. This reinforcement helps to prevent cracking, increase load-bearing capacity, and enhance the overall performance and lifespan of the concrete construction.

- Q: What are the properties of heat-resistant steel for high-temperature applications?

- Heat-resistant steel for high-temperature applications possesses several key properties. Firstly, it has a high melting point, allowing it to withstand extreme temperatures without deformation or failure. Additionally, it exhibits excellent thermal stability, maintaining its mechanical strength and structural integrity even at elevated temperatures. Heat-resistant steel also possesses good oxidation resistance, preventing the formation of scale or oxide layers when exposed to oxygen-rich environments. Furthermore, it has low thermal expansion, reducing the risk of thermal stress and cracking. Lastly, heat-resistant steel often has good creep resistance, enabling it to withstand prolonged exposure to high temperatures without significant deformation or failure.

- Q: What are the properties of stainless steel for medical equipment?

- Stainless steel for medical equipment exhibits several key properties such as high corrosion resistance, excellent strength and durability, good heat resistance, and ease of sterilization. It is also non-reactive, biocompatible, and resistant to bacteria growth, making it a suitable material for surgical instruments, implants, and other medical devices.

- Q: How is steel used in the manufacturing of packaging materials?

- Steel is commonly used in the manufacturing of packaging materials due to its strength and durability. It is often used to create cans and containers, providing a secure and protective packaging solution for various products, such as food, beverages, and household goods. Steel packaging materials are able to withstand the rigors of transportation and storage, ensuring the preservation and safety of the enclosed products. Additionally, steel is recyclable, making it an environmentally friendly choice for packaging materials.

Send your message to us

Aluminum composite board,hot sell aluminium clad composite panel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords