Cold Rolled C Channel with High Quality C140/C160

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t

- Supply Capability:

- 15000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Specifications of Cold Rolled C Channel with High Quality C140/C160:

1.Our Cold Rolled C Channel with High Quality C140/C160 has lots of advantages, just as followings:

a) At reasonable price and good quality.

b) To be convenient in construction and to save much time and labor.

c) The length of Cold Rolled C Channel can be manufactured according to customer’s requirements.

d) The Cold Rolled C Channel has strong mechanical strength.

e). The Cold Rolled C Channel possesses various kind of fittings, through which it is suitbal for many combinations.

The detailed sections of Cold Rolled C Channel with High Quality C140/C160 as per GB standard:

| Model | Section size | |||

| h(mm) | b(mm) | a(mm) | s(mm) | |

| C140 | 140 | 50 | 20 | 1.6-3.2 |

| C140 | 140 | 60 | 20 | 1.6-3.2 |

| C160 | 160 | 50 | 20 | 1.6-3.2 |

The mechanical property of MS Cold Rolled C Channel with High Quality C140/C160 according to Q235B:

Alloy No | Grade | Yielding Strength Point(Mpa) | |||

Thickness(mm) | |||||

≦16 | >16-40 | >40-60 | >60-100 | ||

≧ | |||||

Q235 | B | 235 | 225 | 215 | 205 |

Alloy No | Grade | Tensile Strength(Mpa) | Elongation After Fracture(%) | |||

Thickness(mm) | ||||||

≦16 | >16-40 | >40-60 | >60-100 | |||

≧ | ||||||

G235 | B | 375-500 | 26 | 25 | 24 | 23 |

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered by OKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will arrange production. The shipping date is dependent upon the quatity, how many sizes you want and the plan of production, but is typically 1 month to 2 months from the beginning of production.

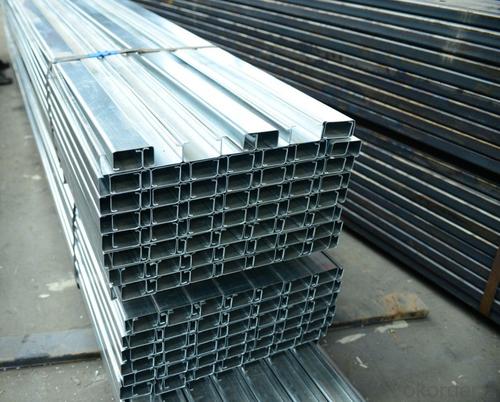

Images of Cold Rolled C Channel with High Quality C140/C160:

*If you would like to get our price, please inform us the size, standard/material and quantity. Thank you very much for your attention.

- Q: How is steel used in the production of medical equipment?

- Steel is commonly used in the production of medical equipment due to its strength, durability, and resistance to corrosion. It is used in surgical instruments, implantable devices, hospital beds, and various other medical tools and equipment.

- Q: What are the properties and characteristics of different steel products?

- Different steel products have varying properties and characteristics based on their composition, manufacturing process, and intended use. Some common properties include high strength, durability, and excellent corrosion resistance. Additionally, steel products can have different mechanical properties, such as hardness, ductility, and toughness, depending on their specific grade and heat treatment. These properties make steel products suitable for a wide range of applications, including construction, automotive manufacturing, and household appliances.

- Q: How do steel products compare to other materials in terms of strength and durability?

- Steel products are widely recognized for their exceptional strength and durability compared to other materials. Steel's innate strength allows it to withstand heavy loads, resist deformation, and maintain its structural integrity over time. Additionally, steel's durability enables it to endure harsh environmental conditions, resist corrosion, and have a longer lifespan compared to many other materials. Overall, steel products consistently demonstrate superior strength and durability, making them a preferred choice in numerous industries.

- Q: What are the advantages of using steel products in construction?

- There are several advantages of using steel products in construction. Firstly, steel is known for its exceptional strength and durability, making it a reliable choice for constructing buildings, bridges, and other structures. It can withstand harsh weather conditions, earthquakes, and fire, ensuring the safety of the occupants. Secondly, steel is highly versatile and can be easily molded into various shapes and sizes, allowing for flexibility in design and construction. Additionally, steel is a sustainable material as it can be recycled, reducing the environmental impact of construction projects. Lastly, steel offers cost-effectiveness in the long run as it requires minimal maintenance and has a longer lifespan compared to other materials.

- Q: How is steel used in the transportation industry?

- Steel is used extensively in the transportation industry for various applications such as building vehicles, manufacturing railway tracks, constructing bridges, and designing infrastructure. It provides strength, durability, and impact resistance, making it an ideal material for ensuring the safety and reliability of transportation systems.

- Q: What are the properties of galvanized steel for outdoor applications?

- Galvanized steel is known for its excellent corrosion resistance, making it highly suitable for outdoor applications. Its protective zinc coating forms a barrier between the steel and the elements, preventing rust and corrosion from forming. This coating also provides a durable and long-lasting finish, ensuring that galvanized steel can withstand exposure to harsh weather conditions, moisture, and UV rays. Additionally, galvanized steel is known for its strength and toughness, making it a reliable choice for outdoor structures, fences, roofing, and other applications where durability is essential.

- Q: What are the uses of steel in the construction of hotels and resorts?

- Steel is widely used in the construction of hotels and resorts due to its exceptional strength and durability. It serves various purposes such as providing structural support, forming the framework of the building, and reinforcing concrete structures. Steel beams and columns are used to create large open spaces, allowing for flexible and efficient floor plans. Additionally, steel is utilized in the construction of staircases, elevator shafts, and roofing systems. Its fire-resistant properties and ability to withstand extreme weather conditions make it an ideal choice for ensuring the safety and longevity of hotels and resorts.

- Q: What are the common types of steel products used in the fashion and apparel industry?

- The common types of steel products used in the fashion and apparel industry include steel buttons, zippers, buckles, and snaps. These steel components are used to enhance the design and functionality of clothing and accessories, providing durability and a sleek aesthetic appeal.

- Q: What are the different types of steel bolts and their uses in the construction of power plants?

- There are several types of steel bolts commonly used in the construction of power plants. Some of the most common types include anchor bolts, structural bolts, and high-strength bolts. Anchor bolts are used to secure equipment, machinery, and structures to the concrete foundation in power plants. They provide stability and prevent movement or displacement. Structural bolts, on the other hand, are used for connecting steel members together in power plant structures. These bolts are designed to withstand high loads and provide structural integrity to the plant's framework. High-strength bolts are specifically designed to withstand extreme forces and provide the necessary strength for critical connections. They are commonly used in the construction of power plants to connect heavy equipment, turbine foundations, and other crucial components. Overall, these different types of steel bolts play a vital role in ensuring the safety, stability, and structural integrity of power plants during their construction process.

- Q: What are the different types of steel wire ropes and their uses in marine applications?

- There are several types of steel wire ropes used in marine applications, each with its own specific use. Some common types include galvanized wire ropes, stainless steel wire ropes, and non-rotating wire ropes. Galvanized wire ropes are coated with a protective layer of zinc, making them resistant to corrosion and ideal for use in marine environments. Stainless steel wire ropes, on the other hand, are highly corrosion-resistant and are often used in applications where strength and durability are crucial, such as mooring lines or lifting equipment. Non-rotating wire ropes are designed to minimize twisting and spinning, making them suitable for tasks that require precise control and stability, such as crane operations. Overall, the choice of steel wire rope depends on the specific marine application and the desired characteristics of strength, corrosion resistance, and stability.

Send your message to us

Cold Rolled C Channel with High Quality C140/C160

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t

- Supply Capability:

- 15000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords