Hot Rolled Steel Strip Coils Professional Manufacturer in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 33 m.t.

- Supply Capability:

- 4433222 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Applications of Steel Strip Coils:

1:Chemical industry equipment, Industrial tanks

2:Medical Instruments,Tableware, Kitchen utensil,kitchen ware

3:Architectural purpose, Milk & Food processing facilities

4:Hospital Equipment, interior Exterior decoration for building

5:Architectural purposes, escalators, kitchen ware,vehicles

Festures of Steel Strip Coils:

Standards: Q195 SGCC DX51D

Other steel grade can be provided after negotiating with customers.

Size: thickness 0.08-5mm, width 10-950mm

Packing: Seaworthy packing.

Specifications of Steel Strip Coils:

| Description | Hot Rolled Steel Strip |

| Brand | Tianjin Metallurgical No.Steel Group |

| Specification | 1.2-6.0mm*70mm |

| Standard | AISI,ASTM,BS,DIN,GB,JIS |

| Material | Q195,Q215,Q215B,Q235,Q235B |

| Application | Widly used in welding steel pipes, and bicycle making etc. |

| Certificates | BV,SGS,ISO etc. |

| MOQ | 20 tons or according to customers’ requirement. |

| Port of Delivery | Tianjin Port of China |

| Remarks | We can provide qualify goods,competitive price and speedy delivery |

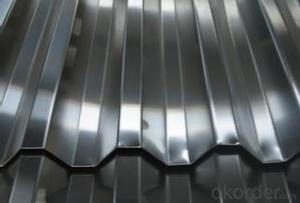

Images of Steel Strip Coils:

FAQ

1.What's your MOQ?

25MT, it is for one container.

2.Do you have QC teams?

Yeah, sure, our QC team is very important, they will keep the quality control for our products.

3. What's your normal delivery time?

Our delivery time about 10-20days for standard sizes, if you have other requirements like hardness and width ,it is about 20-40days.

- Q: How are steel strips used in the construction of pipelines?

- Steel strips are used in the construction of pipelines as they are rolled into cylindrical shapes to form the main body of the pipeline. These strips are welded together to create a continuous and durable structure that can withstand high pressure and transport fluids or gases over long distances. Additionally, the steel strips provide strength, stability, and corrosion resistance to ensure the integrity and longevity of the pipeline system.

- Q: What are the different techniques used for cutting steel strips?

- There are several techniques commonly used for cutting steel strips, including shearing, slitting, and laser cutting.

- Q: How are steel strips used in the production of food processing equipment?

- Steel strips are commonly used in the production of food processing equipment due to their durability and corrosion-resistant properties. These strips are typically used to construct various components of the equipment, such as frames, supports, and panels, ensuring the overall strength and longevity of the machinery. Additionally, steel strips can be shaped and molded into specific forms, allowing for customized designs that meet the specific requirements and functionality of food processing equipment.

- Q: What are the factors that affect the weldability of steel strips?

- There are several factors that can affect the weldability of steel strips. 1. Carbon content: The carbon content of the steel strip plays a significant role in determining its weldability. Higher carbon content can lead to increased hardness and reduced weldability due to the formation of hard and brittle welds. 2. Alloying elements: The presence of alloying elements in the steel strip can also affect its weldability. Some alloying elements, such as chromium and nickel, can improve the weldability by increasing the strength and reducing the risk of cracking. However, other elements, such as sulfur and phosphorus, can have a detrimental effect on weldability by causing porosity and brittleness. 3. Heat treatment: The heat treatment of the steel strip can impact its weldability. Certain heat treatments, such as quenching and tempering, can improve the mechanical properties and weldability of the steel strip by reducing residual stresses and improving grain structure. On the other hand, improper heat treatment can lead to poor weldability due to the formation of undesirable microstructures. 4. Surface condition: The condition of the steel strip's surface can also affect its weldability. A clean and properly prepared surface is essential for achieving a sound and defect-free weld. Contaminants such as oil, grease, rust, or scale can hinder the welding process and lead to weak welds. 5. Thickness and width of the strip: The thickness and width of the steel strip can influence its weldability. Thicker and wider strips may require more heat input and higher welding currents to achieve proper fusion and penetration. Additionally, the geometry of the strip can affect the accessibility and ease of welding, especially in complex joint configurations. 6. Welding process and parameters: The choice of welding process, such as arc welding, resistance welding, or laser welding, can impact the weldability of steel strips. Each welding process has its own set of requirements and limitations. Welding parameters, including welding current, voltage, travel speed, and heat input, need to be carefully controlled to ensure proper fusion, minimize distortion, and prevent defects like porosity or cracking. 7. Base metal cleanliness: The cleanliness of the base metal, including the presence of impurities or inclusions, can affect the weldability of steel strips. Inclusions or impurities can act as stress concentration points, leading to the initiation of cracks during welding. Overall, the weldability of steel strips is a complex interplay of various factors, and it is crucial to consider and optimize these factors to achieve high-quality and reliable welds.

- Q: How are steel strips straightened?

- Leveling or flattening is the method utilized to straighten steel strips. This technique is executed using specialized machinery, namely levelers or flatteners. To initiate the process, the steel strip is introduced into the leveler, which comprises a series of small-diameter rolls arranged consecutively. These rolls are strategically positioned to gradually bend the strip in the opposite direction of its existing curvature. While the steel strip progresses through the leveler, the rolls exert pressure on the convex side of the strip, gradually diminishing its curvature. The number and spacing of the rolls can be adjusted to accommodate various thicknesses and widths of steel strips. In addition to the rolls, levelers may incorporate supplemental features like tension rolls or hydraulic or pneumatic systems to further ensure proper straightening of the steel strip. These additional components aid in applying tension or counteracting any residual stresses in the strip, thereby yielding a straightened final product. In conclusion, the leveling process plays a vital role in guaranteeing the flatness and straightness of steel strips, which is of utmost importance for their subsequent processing and utilization across diverse industries such as automotive, construction, and manufacturing.

- Q: How are steel strips processed for surface grinding?

- Steel strips are processed for surface grinding through a series of steps to ensure a smooth and even finish. The process typically begins with the preparation of the steel strip, which involves cleaning and removing any contaminants or rust using a degreasing agent or chemical solution. This step is crucial as it ensures a clean surface for the subsequent grinding process. Once the steel strip is properly cleaned, it is fed into a grinding machine where the actual surface grinding takes place. The machine consists of a rotating grinding wheel or abrasive belt that removes material from the surface of the steel strip. The speed and pressure of the grinding wheel or belt can be adjusted to achieve the desired finish and remove any imperfections or surface irregularities. During the grinding process, coolant or oil may be used to lubricate the grinding wheel and cool the steel strip, preventing overheating and ensuring a consistent finish. This helps in maintaining the integrity of the steel strip and avoiding any potential damage. After the surface grinding is complete, the steel strip is inspected for any remaining imperfections or inconsistencies. If necessary, additional grinding may be performed to achieve the desired surface quality. Finally, the steel strip is cleaned again to remove any residue or debris from the grinding process. This is done using a cleaning agent or solvent, ensuring the strip is ready for further processing or application. Overall, the process of surface grinding steel strips involves careful preparation, precise grinding, and thorough inspection to achieve a smooth and even finish. This process is essential in various industries where steel strips are used, such as automotive, construction, and manufacturing, as it ensures the quality and functionality of the final product.

- Q: How are steel strips typically stored and transported?

- Steel strips are typically stored and transported in a variety of ways to ensure their safety and efficiency. In terms of storage, steel strips are usually stacked in a vertical position. This allows for easy access and organization, as well as minimizing the risk of damage. The strips are often separated by wooden or steel spacers to prevent any contact between them, which could cause scratching or deformation. Additionally, steel strips are typically stored in a covered warehouse or under a protective roof to shield them from the elements and prevent rusting. When it comes to transportation, steel strips are commonly transported by trucks or trains. They are loaded onto flatbed trailers or rail cars, securely fastened to prevent shifting or movement during transit. To protect the strips from damage during transportation, they are often wrapped in plastic or strapped together using metal bands. This ensures that the strips remain intact and undamaged during the journey. In some cases, steel strips may also be transported by ships or airplanes for longer distances or international shipments. When transported by ship, the strips are usually loaded into containers and secured to prevent any movement. Air transportation typically involves packaging the steel strips in specially designed crates or pallets that provide extra protection. Overall, the storage and transportation of steel strips involve careful attention to detail and proper handling techniques to ensure their safety and integrity.

- Q: Are steel strips suitable for making shelving units?

- Indeed, shelving units can be made using steel strips. Steel, being a robust and long-lasting material, is well-suited for bearing substantial weights. It is effortlessly moldable into different dimensions and shapes, facilitating personalized and adaptable designs for shelving units. Furthermore, steel's resistance to corrosion guarantees the durability of the shelving units, particularly in areas with excessive moisture or humidity. Moreover, the sleek surface of steel strips simplifies the cleaning and upkeep of the shelving units. Ultimately, steel strips prove to be a dependable and pragmatic option for constructing shelving units, providing strength, durability, versatility, and longevity.

- Q: How are steel strips joined together?

- Steel strips are typically joined together using various welding techniques, such as electric resistance welding, laser welding, or arc welding. These methods involve melting the edges of the steel strips and fusing them together to form a strong and durable joint.

- Q: Are steel strips suitable for making utensils?

- Yes, steel strips are suitable for making utensils. Steel is a durable and strong material that can withstand high temperatures and resist corrosion. It is commonly used in the production of kitchen utensils due to its versatility and ability to be easily shaped and molded into various forms.

Send your message to us

Hot Rolled Steel Strip Coils Professional Manufacturer in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 33 m.t.

- Supply Capability:

- 4433222 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords