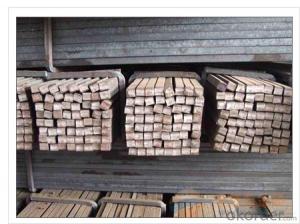

Hot Rolled Low Carbon Steel Square Bars

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Hot Rolled Low Carbon Steel Square Bars at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to African, South American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Hot Rolled Low Carbon Steel Square Bars are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Hot Rolled Low Carbon Steel Square Bars are durable, strong, and wide variety of sizes.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Manufacture: Hot rolled

Grade: Q195 – 235

Certificates: ISO, SGS, BV, CIQ

Length: 6m – 12m, as per customer request

Packaging: Export packing, nude packing, bundled

| SQUARE BAR | |

| SIZE a(mm) | theoretical kg/m |

| 5.5 | 0.237 |

| 6 | 0.283 |

| 7 | 0.385 |

| 8 | 0.502 |

| 9 | 0.636 |

| 10 | 0.785 |

| 11 | 0.95 |

| 12 | 1.13 |

| 13 | 1.33 |

| 14 | 1.54 |

| 15 | 1.77 |

| 16 | 2.01 |

| 17 | 2.27 |

| 18 | 2.54 |

| 19 | 2.83 |

| 20 | 3.14 |

| 21 | 3.46 |

| 22 | 3.8 |

| 24 | 4.52 |

| 25 | 4.91 |

| 26 | 5.31 |

| 28 | 6.15 |

| 30 | 7.06 |

| 32 | 8.04 |

| 34 | 9.07 |

| 36 | 10.2 |

| 38 | 11.3 |

| 40 | 12.6 |

| 42 | 13.8 |

| 45 | 15.9 |

| 48 | 18.1 |

| 50 | 19.6 |

| 53 | 22 |

| 56 | 24.6 |

| 60 | 28.3 |

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How many tons of steel products could be loaded in containers?

A3: Usually the steel products are delivered by bulk vessel because of the large quantity and the freight. However, there are no bulk vessel enter some seaports so that we have to deliver the cargo by containers. The 6m steel product can be loaded in 20FT container, but the quantity is changed according to the size, usually from 18tons to 25tons.

Images:

- Q: How do you use a steel square to determine the angle of a compound taper cut?

- To determine the angle of a compound taper cut, one must follow these steps: 1. Place the steel square on the material's surface or edge where the taper cut will be executed, ensuring that the square's long side aligns with the material's length. 2. Adjust the square so that one arm runs parallel to the material's surface or edge. This arm will serve as a reference line for angle measurement. 3. Utilize a protractor or angle finder to measure the angle between the reference line of the square and the material's surface or edge. Position the protractor against the square's perpendicular arm. 4. Take note of the angle measurement, which will determine the required angle for the taper cut. 5. Transfer the angle measurement to the saw or cutting tool being used. Most saws have a bevel or miter gauge that allows for angle adjustment. Set the gauge to the measured angle and secure it in place. 6. Align the material with the saw or cutting tool's blade, ensuring that the steel square's reference line remains parallel to the saw's fence or guide. 7. Execute the compound taper cut carefully, either following the marked line or using the saw's fence or guide as a reference. By utilizing a steel square to measure the angle of a compound taper cut, one can achieve precise and accurate cuts, resulting in a professional-looking finished product.

- Q: Can a steel square be used for welding?

- Yes, a steel square can be used for welding. A steel square is a versatile tool commonly used in welding to ensure accurate right angles and measurements. It can be used as a guide to check the alignment and squareness of weld joints, ensuring that they are properly positioned and welded at a 90-degree angle. Additionally, a steel square can be used to measure and mark materials before cutting or welding, ensuring precise dimensions. Overall, a steel square is an essential tool in the welding process, aiding in achieving high-quality and accurate welds.

- Q: How do you use a steel square to ensure the correct angle for a finger joint?

- To use a steel square to ensure the correct angle for a finger joint, you would start by marking the desired angle on the edge of the wood. Then, place one arm of the steel square against the edge of the wood and align the other arm with the angle mark. Finally, use a pencil or marking knife to trace along the edge of the steel square, creating a precise guideline for cutting the finger joint.

- Q: How is a steel square calibrated?

- A steel square is calibrated by ensuring that all its angles and measurements are accurate through a process of precision machining and quality control.

- Q: Can a steel square be used for cutting wood?

- No, a steel square is not typically used for cutting wood. Its primary purpose is for measuring and marking angles and straight lines in woodworking projects.

- Q: How do you use a steel square to mark out 75-degree angles?

- To use a steel square to mark out 75-degree angles, you would typically align the 45-degree angle of the square with the edge of the material. Then, using a protractor or angle finder, measure 30 degrees from the square's 45-degree angle, which will give you a total of 75 degrees. Finally, draw a line along the edge of the square to mark out the 75-degree angle.

- Q: Can a steel square be used for measuring the thickness of tiles?

- No, a steel square cannot be used for measuring the thickness of tiles. A steel square is a tool primarily used for measuring angles and ensuring accurate 90-degree corners. It is not designed to measure thickness. To determine the thickness of tiles, one would typically use a caliper or a thickness gauge specifically designed for measuring small dimensions. These tools are more precise and provide accurate readings for tile thickness.

- Q: What are the dimensions of a steel square?

- The dimensions of a steel square can vary depending on its specific design or purpose. However, in general, a steel square typically has equal sides that range from 6 inches to 48 inches in length.

- Q: How do you use a steel square to lay out a diamond shape?

- To use a steel square to lay out a diamond shape, start by marking a reference line on the material using the long arm of the square. Then, align the short arm of the square with the reference line and mark a point to the left and right of the reference line to create the width of the diamond. Next, rotate the square 45 degrees and align the short arm with the left point previously marked. Mark a point above and below the reference line to determine the height of the diamond. Repeat this step for the right point. Finally, connect the points to form the diamond shape.

- Q: Can a steel square be used for tile corner layout?

- Tile corner layout can be done using a steel square. A steel square, also called a framing square or carpenter's square, is a versatile tool suitable for various layout tasks, including tile corner layout. Its right-angle shape is perfect for guaranteeing accurate and precise corners while laying tiles. By positioning the steel square against the tile corner, you can ensure proper alignment and squareness between tiles. This is especially handy when dealing with large tiles or intricate tile patterns that require precise corner alignment.

Send your message to us

Hot Rolled Low Carbon Steel Square Bars

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords