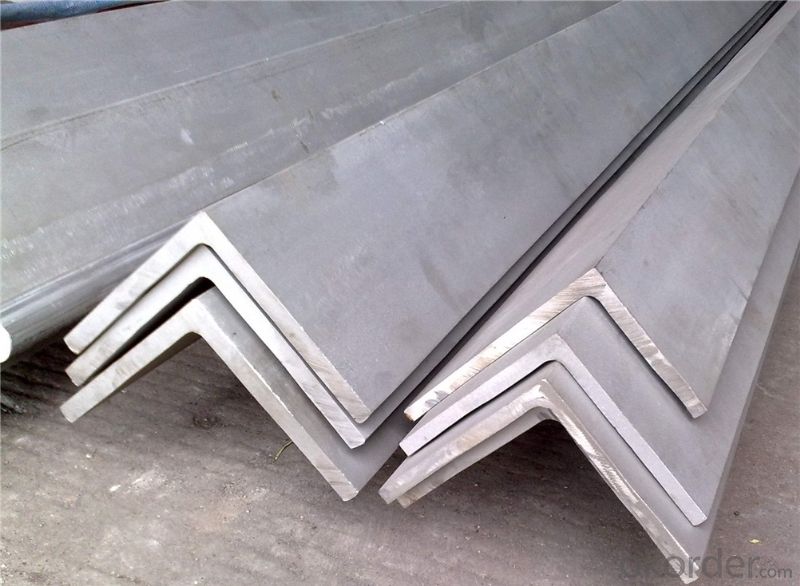

Hot rolled stainless steel angle for construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100000 m.t.

- Supply Capability:

- 2000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description:

OKorder is offering hot rolled stainless steel angle for construction at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Hot rolled stainless steel angle are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Steel angle are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Specifications of Angle Steel

1. Invoicing on theoretical weight or actual weight as customer request

2. Length: 6m, 9m, 12m as following table

1).100% irrevocable L/C at sight.

2).30% T/T prepaid and the balance against the copy of B/L.

3).30% T/T prepaid and the balance against L/C

Packaging & Delivery of Angle Steel

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

Production flow of Angle Steel

Material prepare (billet) —heat up—rough rolling—precision rolling—cooling—packing—storage and transportation

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

- Q: What is the weight-bearing capacity of steel angles?

- The weight-bearing capacity of steel angles depends on various factors such as the dimensions and thickness of the angle, the type of steel used, and the specific load application. Steel angles are commonly used in construction and structural applications due to their strength and load-bearing capabilities. However, it is important to consult engineering tables or consult with a structural engineer to determine the specific weight-bearing capacity of a steel angle in a particular application.

- Q: Can steel angles be used for structural applications?

- Yes, steel angles can be used for structural applications. They are commonly used in construction and engineering projects to provide structural support, stability, and reinforcement. Steel angles have excellent strength-to-weight ratio, high durability, and versatility, making them suitable for various structural applications such as framing, bracing, trusses, and supports.

- Q: What are the standard lengths of steel angles?

- The standard lengths of steel angles vary depending on the specific requirements and standards set by different industries and applications. However, in general, the standard lengths of steel angles can range from 20 feet to 40 feet. These lengths are commonly used in construction, manufacturing, and structural applications. It is important to note that steel angles can also be cut and customized to specific lengths based on the project's needs.

- Q: What are the standard dimensions for equal leg steel angles?

- The standard dimensions for equal leg steel angles vary depending on the industry and country. However, in general, the standard dimensions for equal leg steel angles are typically measured in terms of the length of each leg and the thickness of the angle. Common dimensions include leg lengths ranging from 20mm to 200mm, with thicknesses ranging from 3mm to 20mm. These dimensions are often specified in millimeters and can be further customized to meet specific project requirements. It is important to consult industry standards and specifications to determine the exact dimensions for equal leg steel angles in a particular context.

- Q: Can steel angles be used in seismic or earthquake-resistant construction?

- Seismic or earthquake-resistant construction can indeed make use of steel angles. These angles are commonly employed in structural applications due to their ability to provide strength and stability to a building. The main objective in seismic construction is to create structures capable of withstanding the powerful forces unleashed by an earthquake. Steel angles can be utilized in various ways to enhance a structure's resistance to seismic activity. One common application involves using them as bracing elements. These bracing systems help distribute the seismic forces throughout the building, reducing the risk of collapse. Steel angles can be employed as diagonal bracing members, adding strength and rigidity to the structure. Furthermore, steel angles can serve as moment-resisting frames in seismic design. These frames are designed to dissipate and absorb the energy generated during an earthquake. By incorporating steel angles into the frame, the building can effectively counteract lateral forces and maintain stability during seismic events. Moreover, steel angles are crucial in the construction of steel moment frames, which are widely used in seismic design. These frames consist of steel columns and beams connected by steel angles or other connections capable of resisting earthquake-induced forces. Steel angles play a vital role in transferring forces between different frame members, ensuring overall stability and structural integrity. In conclusion, steel angles can be effectively utilized in seismic or earthquake-resistant construction. Their strength and versatility make them suitable for bracing systems, moment-resisting frames, and steel moment frames, all of which contribute to enhancing a structure's seismic resistance. However, it is essential to ensure that the design and installation of steel angles comply with relevant building codes and regulations to guarantee the safety and durability of the construction.

- Q: Can steel angles be used for electrical conduits?

- No, steel angles cannot be used for electrical conduits as they are not designed or suitable for carrying electrical wiring. Electrical conduits are typically made of materials such as PVC, steel, or aluminum that are specifically designed to safely enclose and protect electrical wires.

- Q: Can steel angles be used in conveyor systems or material handling equipment?

- Yes, steel angles can be used in conveyor systems or material handling equipment. Steel angles, also known as angle iron, are commonly used in these applications due to their structural strength and versatility. They can be easily welded, bolted, or riveted together to create various framework structures for conveyors and material handling equipment. Steel angles provide stability, support heavy loads, and can be used to construct frames, supports, and guards for conveyor belts, rollers, chutes, and other components. Additionally, steel angles are available in various sizes and thicknesses to suit different application requirements, making them a popular choice in the construction of conveyor systems and material handling equipment.

- Q: Can steel angles be drilled or punched for fastening?

- Fastening steel angles is possible through drilling or punching. These angles are commonly utilized in the construction and manufacturing industries due to their structural strength and versatility. To attach steel angles to other materials or join them together, the most common method is to drill or punch holes. Drilling involves the use of a drill bit to create precise holes in steel angles. This method is suitable when the angle needs to be attached to a specific location. The drilling process can be performed manually or with the assistance of drilling machines, depending on the project's scale. On the other hand, punching involves the use of a punch and die set to create holes in steel angles. This method is faster and more efficient, especially when dealing with large quantities of angles. Punching machines can create holes of different sizes and shapes, making it suitable for various fastening requirements. Once the holes are drilled or punched, fastening can be achieved using bolts, screws, or rivets. These fasteners are inserted through the holes and tightened to securely hold the steel angles together or attach them to other materials. The choice of fastening method depends on the specific application and load requirements. To summarize, drilling or punching holes in steel angles is a viable option for fastening. Whether it's attaching steel angles to other materials or joining them together, drilling or punching provides reliable and secure fastening solutions for construction and manufacturing projects.

- Q: How are steel angles tested for quality and strength?

- Steel angles are tested for quality and strength through various methods to ensure they meet the required standards and specifications. One of the primary tests conducted on steel angles is the tensile test, which measures the material's resistance to breaking under tension. This test involves applying a gradually increasing load to a sample of the steel angle until it reaches its breaking point. The maximum load the angle can withstand is measured, and this provides critical information about its tensile strength. Another important test is the hardness test, which determines the steel angle's resistance to indentation. This test helps to assess the material's ability to withstand wear and tear, as well as its overall strength. Hardness is typically measured using the Rockwell or Brinell scales, where a harder material indicates higher strength. To ensure the steel angle's quality, it also undergoes visual inspections for any surface defects, such as cracks, uneven surfaces, or deformities. These inspections are conducted by trained professionals who carefully examine the angles for any imperfections that may compromise their structural integrity. In addition to these tests, steel angles may also undergo chemical composition analysis to verify that the material meets the required specifications. This analysis determines the percentage of various elements present in the steel, such as carbon, manganese, and sulfur, which directly impact the angle's strength and durability. Overall, steel angles are rigorously tested for quality and strength through a combination of physical, visual, and chemical tests. These tests ensure that the angles can withstand the intended loads and perform safely in various applications, providing confidence in their reliability and longevity.

- Q: How are steel angles inspected for quality and compliance with standards?

- Steel angles are inspected for quality and compliance with standards through a series of rigorous tests and inspections. These inspections are carried out by qualified personnel, often trained and certified in non-destructive testing (NDT) methods. The inspection process begins with a visual examination of the steel angles, looking for any surface defects such as cracks, pits, or sharp edges. This examination ensures that the angles are free from any visible defects that may compromise their strength and structural integrity. Next, dimensional checks are performed to verify that the steel angles meet the specified dimensions and tolerances as outlined in the applicable standards. This includes measuring the length, width, thickness, and other critical dimensions to ensure they align with the required specifications. To evaluate the internal soundness of the steel angles, non-destructive testing methods are employed. These methods include ultrasound testing (UT), magnetic particle testing (MT), liquid penetrant testing (PT), and radiographic testing (RT). UT uses high-frequency sound waves to detect any internal flaws or discontinuities, while MT and PT involve the application of magnetic particles or liquid dyes to detect surface cracks or defects. RT, on the other hand, uses X-rays or gamma rays to inspect the internal structure of the steel angles. Mechanical tests are also conducted to assess the mechanical properties of the steel angles. These tests may include tensile testing, which measures the strength and elasticity of the material, and hardness testing, which determines the resistance of the steel to indentation or scratching. These tests ensure that the steel angles possess the required mechanical strength and properties as specified by the standards. Furthermore, chemical analysis is carried out to verify the chemical composition of the steel angles, particularly the levels of various alloying elements. This analysis ensures that the steel meets the required chemical composition standards, which directly influence its strength, corrosion resistance, and other properties. In addition to these inspections, steel angles may also undergo surface treatment testing, such as coating thickness measurement, adhesion testing, or salt spray testing, to ensure that any protective coatings or finishes applied meet the required standards. Overall, the inspection process for steel angles is comprehensive and involves a combination of visual examinations, dimensional checks, non-destructive testing, mechanical tests, chemical analysis, and surface treatment testing. These inspections are crucial to ensure that the steel angles meet the necessary quality and compliance standards, providing confidence in their performance and reliability in various applications.

Send your message to us

Hot rolled stainless steel angle for construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100000 m.t.

- Supply Capability:

- 2000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords