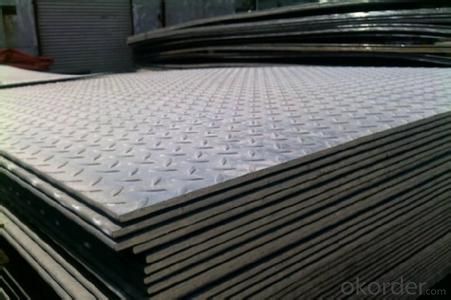

Hot Rolled Checkered Steel Plate of High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 200 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Hot Rolled Checkered Steel Plate Description

Widely used in petrochemistry,chemistry,electricity,boiler and vessel manufacture,and could be made into reactor,

heat exchange facility,segregator,sphere vessel,oil tank,liquid gas storage tank,nuclear reactor press shell,turbine and other machines.

2.Main Features of the Hot Rolled Checkered Steel Plate

•Hot Rolled & Annealing

•Good Quality & Fast Delivery

•Competitive Price & Nice Service

3. Hot Rolled Checkered Steel Plate Images

4. Hot Rolled Checkered Steel Plate Specification

Thickness | 2-100mm |

Width | 1250mm,1500mm,1800mm,2000mm.,2500mm or as required |

Length | 2000-12000mm |

Standard | AISI, ASTM, BS, DIN, GB, JIS |

Material | A36,SS400,SPCC,SPHC, Q195, Q 235,Q345 |

Tehnique | Hot rolled;cold rolled |

Payment | TT ,L/C |

Packing | Standard seaworthy packing or as required |

Market | Mild east, North/South America, Europe, Asia,Africa etc |

Certificate | BV,SGS,MTC |

Delivery time | Within 7-10 days |

5.FAQ of Hot Rolled Checkered Steel Plate

①Condition of Delivery

According to user requirements, can be Hot rolled, normalizing, tempering, normalizing and tempering, quenching and other delivery.

②Which Standard?

According to user requirements, can be delivered the following criteria: national standards, metallurgical industry standards, the United States ASTM, ASME standards, Japanese JIS, German DIN, British BS, European EN, the international ISO standards and the standards specific board and so on.

③What's the usage?

Making pipes, cold strip-welded pipes, cold-bent shaped-steel, bicycle structures, small-sized press-pieces and household decoration goods

- Q: What is the typical electrical conductivity of a steel sheet?

- The typical electrical conductivity of a steel sheet is relatively low compared to other metals. Steel is considered to be a poor conductor of electricity, with a conductivity ranging from 6.99 to 9.71 million siemens per meter (MS/m), depending on the specific type and composition of the steel.

- Q: What is the difference between a smooth and embossed steel sheet?

- A smooth steel sheet is characterized by its flat and uniform surface, lacking any textures or patterns. It is typically produced by rolling the steel through a series of rollers to achieve a sleek and even finish. Smooth steel sheets are commonly utilized in industries where a seamless and polished appearance is desired, such as in architectural and interior design, automotive manufacturing, and appliance production. On the other hand, an embossed steel sheet possesses a textured or patterned surface. This texture is created by pressing the steel sheet between embossing rollers, which imprint a design onto the surface. The embossed pattern can take various shapes, including diamonds, squares, or waves, and it adds a decorative and tactile element to the sheet. Embossed steel sheets are often employed in industries like furniture manufacturing, signage production, and decorative metalwork. In terms of functionality, smooth steel sheets are typically chosen for applications that require a clean and unadorned surface, such as for painting, coating, or other surface treatments. They serve as a blank canvas for further customization or finishing processes. In contrast, embossed steel sheets provide a visually appealing and distinctive texture that can enhance the aesthetic appeal of a product or structure without the need for additional surface treatments. Furthermore, the surface texture of a smooth steel sheet tends to be more resistant to fingerprints, smudges, and dirt accumulation compared to an embossed steel sheet. This makes smooth steel sheets easier to clean and maintain in applications where cleanliness is crucial, such as in the food processing or healthcare industries. Overall, the primary distinction between a smooth and embossed steel sheet lies in their appearance, functionality, and suitability for specific applications. While smooth steel sheets offer a clean, consistent, and versatile surface, embossed steel sheets provide a decorative and textured finish that can elevate the visual appeal of a product or structure.

- Q: Can the steel sheets be easily painted or coated?

- Indeed, it is possible to effortlessly paint or coat steel sheets. The sleek texture of these sheets enables exceptional paint or coating adherence. Before proceeding with the painting or coating process, it becomes crucial to diligently cleanse the surface to eliminate any potential dirt, grease, or rust that may hinder proper adhesion. Additionally, the utilization of a primer or base coat can considerably augment the resilience and longevity of the applied paint or coating. In summary, steel sheets furnish a fitting and conveniently paintable surface for an array of purposes.

- Q: Are the steel sheets resistant to oil or grease?

- Yes, steel sheets are generally resistant to oil or grease. Steel is known for its durability and resistance to various chemicals, including oil and grease. The smooth surface of steel sheets makes it difficult for substances like oil or grease to adhere to them, allowing for easy cleaning and maintenance. Additionally, steel sheets can be further treated or coated with protective materials to enhance their resistance to oil or grease if required.

- Q: How thick are steel sheets typically?

- Steel sheets can vary in thickness depending on their intended use, but they typically range from 0.5 to 6 millimeters thick.

- Q: Can steel sheets be used in HVAC applications?

- Yes, steel sheets can be used in HVAC applications. Steel sheets are commonly used in HVAC systems for various purposes such as ductwork, ventilation, and fabrication of components like air handling units and heat exchangers. Steel offers excellent strength, durability, and resistance to corrosion, making it suitable for these applications.

- Q: What is AO steel plate?

- It is better to meet the anatomical angle and bone surface in steel plate and Futie professional medical professional operation, to fracture the bones to firm, stable and maximum support.

- Q: Are steel sheets suitable for battery enclosures or casings?

- Yes, steel sheets are suitable for battery enclosures or casings. Steel is a durable and strong material that can provide sufficient protection for batteries against external forces and impacts. Additionally, steel sheets can resist heat and fire, making them a reliable choice for battery enclosures.

- Q: Are steel sheets suitable for elevator shafts or cabin interiors?

- Yes, steel sheets are suitable for both elevator shafts and cabin interiors. Steel is a widely used material in the construction industry due to its strength, durability, and versatility. When it comes to elevator shafts, steel sheets are commonly used for their ability to withstand heavy loads and provide structural support. They offer excellent fire resistance and can withstand extreme temperatures, making them a safe choice for elevator shafts. In terms of cabin interiors, steel sheets offer various advantages. They can be easily fabricated into different shapes and sizes, allowing for customization and flexibility in design. Steel sheets can be painted or coated to provide a smooth and aesthetically pleasing finish. They are also highly resistant to wear and tear, ensuring long-term durability in a high-traffic area like an elevator cabin. Moreover, steel sheets are known for their soundproofing properties, which is crucial for elevator cabins to provide a comfortable and quiet experience for passengers. They are also resistant to moisture and corrosion, making them suitable for elevator cabins in humid or coastal areas. Overall, steel sheets are an excellent choice for elevator shafts and cabin interiors due to their strength, durability, versatility, fire resistance, soundproofing capabilities, and resistance to moisture and corrosion.

- Q: Can steel sheets be used in marine applications?

- Yes, steel sheets can be used in marine applications. Steel is a common material used for constructing ships, offshore platforms, and other marine structures due to its high strength, durability, and resistance to corrosion in saltwater environments.

Send your message to us

Hot Rolled Checkered Steel Plate of High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 200 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords